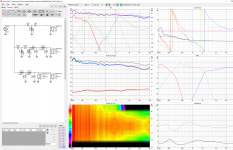

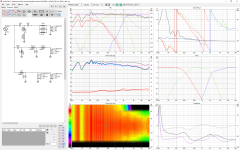

I have been simulating steeper crossovers, not a 100% success. Really just wanted to see if I could get something with better filtering of the breakups and possibly better power handling. Main issue I am running into is that the impedance goes way too low, 2.3 Ohms at 440 Hz.

Tried so searches to see what I should do about low impedance and didn't really see a solution. I based my filters off of the library filters so I don't think I am far off reasonable values.

Tried so searches to see what I should do about low impedance and didn't really see a solution. I based my filters off of the library filters so I don't think I am far off reasonable values.

Attachments

I have started in on the cabinet building. Each speaker uses a full sheet of 4'x8'. I will post the cut list later, would be a good cabinet for a variety of 8" woofer 3 ways.

Images:

My table saw set up with cut down ikea table for outfeed. Turn it 90 and you have some support for cross cuts.

The sheet of plywood broken down and ready for routing.

Bracing template with the hole and jig saw.

Bracing with rough jig saw cut outs and cleaned up against the template with the router. 3/8" round over to come.

Just a few clamps for the front panel glue up.

Router with custom long support so I can get around the woofer cutouts without loosing control.

Dry fit with a good view of the driver bevels.

Woops, I had some tightbond II I wanted to use up. Bad idea, work time was too short in the LA heat. I didn't properly constrain the front to the side panel and my heavy clamping after the fact gave a bit of a ripple on the front panel edge.

Nothing a bit of plastic wood and patience couldn't fix. My woofer rebates were a touch oversized. the hole guide was going to be interference fit or just over, so went with over. Turned out a bit bigger than expected, so some strips of spare mahogany paper backed veneer to tighten things up.

And finally the cross over I think I will start with. Something simple and inexpensive with iron core for the large inductors and electrolytics.

Images:

My table saw set up with cut down ikea table for outfeed. Turn it 90 and you have some support for cross cuts.

The sheet of plywood broken down and ready for routing.

Bracing template with the hole and jig saw.

Bracing with rough jig saw cut outs and cleaned up against the template with the router. 3/8" round over to come.

Just a few clamps for the front panel glue up.

Router with custom long support so I can get around the woofer cutouts without loosing control.

Dry fit with a good view of the driver bevels.

Woops, I had some tightbond II I wanted to use up. Bad idea, work time was too short in the LA heat. I didn't properly constrain the front to the side panel and my heavy clamping after the fact gave a bit of a ripple on the front panel edge.

Nothing a bit of plastic wood and patience couldn't fix. My woofer rebates were a touch oversized. the hole guide was going to be interference fit or just over, so went with over. Turned out a bit bigger than expected, so some strips of spare mahogany paper backed veneer to tighten things up.

And finally the cross over I think I will start with. Something simple and inexpensive with iron core for the large inductors and electrolytics.

Attachments

-

Zhangqi_019.png420.6 KB · Views: 488

Zhangqi_019.png420.6 KB · Views: 488 -

20210619_111253.jpg1 MB · Views: 543

20210619_111253.jpg1 MB · Views: 543 -

20210619_123555.jpg943.9 KB · Views: 479

20210619_123555.jpg943.9 KB · Views: 479 -

20210620_105908.jpg595.5 KB · Views: 418

20210620_105908.jpg595.5 KB · Views: 418 -

20210622_075335.jpg716.3 KB · Views: 191

20210622_075335.jpg716.3 KB · Views: 191 -

20210703_100206.jpg893.7 KB · Views: 205

20210703_100206.jpg893.7 KB · Views: 205 -

20210627_144229.jpg908.8 KB · Views: 219

20210627_144229.jpg908.8 KB · Views: 219 -

20210703_113507.jpg836.7 KB · Views: 222

20210703_113507.jpg836.7 KB · Views: 222 -

20210704_114111.jpg866.5 KB · Views: 224

20210704_114111.jpg866.5 KB · Views: 224 -

20210705_125839.jpg700.4 KB · Views: 229

20210705_125839.jpg700.4 KB · Views: 229

I'm guessing you are using the 4 ohm version of the 5" for the mid range. The reason I say this is because two of the 8 inch woofers will be about 93db where the single 5 inch will only be 86 db where the 4 ohm is 88 db. Either one might not be sensitive enough to keep up but maybe the 4 ohm would give a 5 db baffle step compensation. I think the tweeter will be OK, I would even pad it down a few db just to give it a nice house curve. I use both drivers and they sound good to my old ears.

I'm guessing you are using the 4 ohm version of the 5" for the mid range. The reason I say this is because two of the 8 inch woofers will be about 93db where the single 5 inch will only be 86 db where the 4 ohm is 88 db. Either one might not be sensitive enough to keep up but maybe the 4 ohm would give a 5 db baffle step compensation. I think the tweeter will be OK, I would even pad it down a few db just to give it a nice house curve. I use both drivers and they sound good to my old ears.

Yes I have the 4 ohm midrange with the 8 ohm woofers in parallel. At least from the VituixCAD simulations with the baffle geometry (including roundover) using SB Acoustics traced curves things look nicely level matched. I could boost the low end a bit by switching to a toroidal inductor if needed and shape the crossover region with some shunt resistors. The outstanding question though is the tweeter level, I suspect with the waveguide things are going to run a bit hotter than what is simulated here. Going to have a few spare resistors on hand to deal with that.

After I get the simple cross over dialed in I may revisit for steeper slopes on the woofer or shaping on the tweeter. Just a bit annoying to have to custom wind inductors and such for that.

I still suggest measuring the drivers once they're mounted in the enclosure. The simulated frd are usually slightly off to be reliably used for crossover simulations. Nice project.

If those are the drivers you intend on using then have a search for Javad Shadzi and Jeff Bagby's Cermico speakers on the Facebook Loudspeaker page or on. All of the work is done for you.

Log into Facebook

Log into Facebook

Both cabinets now have the major woodwork done, still the final 1.5" roundover once the box is closed up. Going to be gluing in the bitumen sheets and recycled denim soon.

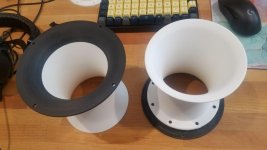

Decided to 3d print a Harmen port in two tone to match my drivers. Turned out nicely, will reprint when I finalize tuning. Matches the mounting of my precision ports so I can switch them around.

Still waiting on backordered crossover components (yes I will measure, saw half my planned components go on backorder and with supply lines being what they are wanted something on hand) and should have the MJF nylon waveguides soon. Getting close!

Decided to 3d print a Harmen port in two tone to match my drivers. Turned out nicely, will reprint when I finalize tuning. Matches the mounting of my precision ports so I can switch them around.

Still waiting on backordered crossover components (yes I will measure, saw half my planned components go on backorder and with supply lines being what they are wanted something on hand) and should have the MJF nylon waveguides soon. Getting close!

Attachments

Decided to build a smaller test box to make sure I could get everything done with something easier to handle.

Really nice routing job getting the tweeter closer to the midrange! 🙂

(..the HiFi Loudspeaker industry should be doing it so well.) 😱

That's awesome you're using the Harman port! Since that box is so much bigger than mine, see if you can calculate the net volume as precisely as possible so we can see if the end correction is close to what I found. What was minimum diameter of the port?

Also when you print the final pieces are you going to try ABS or Polysmooth so you can smooth it? There was a big impact on chuffing when you do.

Also when you print the final pieces are you going to try ABS or Polysmooth so you can smooth it? There was a big impact on chuffing when you do.

That's awesome you're using the Harman port! Since that box is so much bigger than mine, see if you can calculate the net volume as precisely as possible so we can see if the end correction is close to what I found. What was minimum diameter of the port?

Also when you print the final pieces are you going to try ABS or Polysmooth so you can smooth it? There was a big impact on chuffing when you do.

From my 3d model less the bracing, drivers, and port the total woofer cabinet volume is 5600 in3 or 91.7 Liters. On the conservative end 90 Liters, so yes big. The port has a throat diameter of 3 in, overall length of about 6 in, using the .5 ratio and recommended roundover from the paper. May need to go out to 8 in long depending on room gain, have a hard to estimate room with openings.

I am building a printer for ABS, but that probably wont be ready in time. So, instead I will just go for filler primer and sanding with a high gloss coat for the white portion. Vapor smoothing tends to not give good dimensional consistency, so instead tight layers, sanding and painting are going to be better in the end.

I will have to go back through your thread to get the measurement methodology.

Getting good use out of your findings between the waveguide and port.

Progress.

The cabinet in the foreground has a layer of nominal 1" recycled denim throughout (more like .5"). In the background you can see the second cabinet with the bitumen pads and its denim and polyfil on top. Polyfil for the first cabinet coming soon when the vinyl glue gets here. The wiring harness is 16ga with cloth tape wrap. Waveguide is a placeholder with the nylon ones on the way.

Detail of the cabinet interior.

Stainless nuts epoxied into the bottom of the cabinet with furniture levelers for feet. Will swap out or paint black.

Test crossover, found a construction oversight. How to fix it into the cabinet.... have some ideas of how to get some threaded rod in the bottom of the cabinet to secure it.

The cabinet in the foreground has a layer of nominal 1" recycled denim throughout (more like .5"). In the background you can see the second cabinet with the bitumen pads and its denim and polyfil on top. Polyfil for the first cabinet coming soon when the vinyl glue gets here. The wiring harness is 16ga with cloth tape wrap. Waveguide is a placeholder with the nylon ones on the way.

Detail of the cabinet interior.

Stainless nuts epoxied into the bottom of the cabinet with furniture levelers for feet. Will swap out or paint black.

Test crossover, found a construction oversight. How to fix it into the cabinet.... have some ideas of how to get some threaded rod in the bottom of the cabinet to secure it.

Attachments

If those are the drivers you intend on using then have a search for Javad Shadzi and Jeff Bagby's Cermico speakers on the Facebook Loudspeaker page or on. All of the work is done for you.

Log into Facebook

You are right, but they didn used waveguide on tweeter...

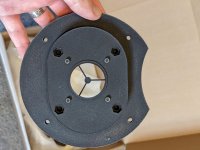

Waveguide is in. MJF PA12 dyed black at 80um (nylon).

Locating pegs for the tweeter are a bit long, easy to sand down. The spokes that hold the phase shield are a little more delicate than intended. Modeled after the stock SB26 tweeter's faceplate, but that is probably stiffer ABS with the larger phase shield so a shorter span.

The differences in my waveguide from the baseline are: Most significantly a round footprint to make the baffle routing simple. Insets for 4 m5 nuts to clamp the tweeter instead of cutting threads in the waveguide. Locating pins changed so that the tweeter is oriented with terminals at the sides. 3 spokes to hold the phase shield, mostly an authentic choice and may give some additional protection. Prerouted for a 150mm midrange to sit as near the acoustic center as possible (4.5 in). A little embossed logo. Screw countersinks to match the hex head screws that will be used for the other drivers.

Profile matches the J revision of the SB26 waveguide.

Locating pegs for the tweeter are a bit long, easy to sand down. The spokes that hold the phase shield are a little more delicate than intended. Modeled after the stock SB26 tweeter's faceplate, but that is probably stiffer ABS with the larger phase shield so a shorter span.

The differences in my waveguide from the baseline are: Most significantly a round footprint to make the baffle routing simple. Insets for 4 m5 nuts to clamp the tweeter instead of cutting threads in the waveguide. Locating pins changed so that the tweeter is oriented with terminals at the sides. 3 spokes to hold the phase shield, mostly an authentic choice and may give some additional protection. Prerouted for a 150mm midrange to sit as near the acoustic center as possible (4.5 in). A little embossed logo. Screw countersinks to match the hex head screws that will be used for the other drivers.

Profile matches the J revision of the SB26 waveguide.

Attachments

Testing is in progress, cranked it a bit to check for issues. Low end is spot on. Midrange might to be getting too much low end just from cone movement, but far field seems fine, detailed driver measurements soon. It is stupid heavy with the drivers in. Going to have to buy a hand truck just to get these in the house.

You can see the start of my sound treatment in the background there. Making a template for a maximum length series panel. Going with 4in of 8lbs rockwool with a 2+in air gap. Should finish our similar to the GIK 6“ alpha panels. Going to treat the back wall with 3 panels and might get away with a chunk in the fireplace. Sidewall treatment isn't an option, but maybe I can get a cloud past WAF.

Already itching to build some subs after this.

You can see the start of my sound treatment in the background there. Making a template for a maximum length series panel. Going with 4in of 8lbs rockwool with a 2+in air gap. Should finish our similar to the GIK 6“ alpha panels. Going to treat the back wall with 3 panels and might get away with a chunk in the fireplace. Sidewall treatment isn't an option, but maybe I can get a cloud past WAF.

Already itching to build some subs after this.

Its moving day, speakers have finally made their way into the house. Fixed my crossover issue, just forgot to connect a crossover element of the midrange to ground. They are big, I'm sure they will feel a part of the room when I get used to them, but really big. Small detail but I airbrush primed the feet black.

I recently got a used Technics Sl-1500C with a Ortofon 2M Bronze that I also need to set up, last turntable I will ever need. My audio setup is a Purifi amp with NC500 buffers, Mini DSP SHD fed by the PC over USB, TV over optical (PS4), and Art DJPRE II Phono Preamplifier over RCA. Cables are the no frills Micca 14ga, they have a good tone to blend in with the brick hearth.

Pictured in their role as a new cat tree, and then with anti cat hole covers.

Veneer still to go, I have AAA Bolivian Rosewood raw wood which will be its own journey. I was going to vacuum bag and all that, but I think I may try heat application given the curvature I have to deal with. Need to get the workshop is good order before attempting that. Veneer is why the top edge isn't rounded, sides have a generous 1.5" roundover.

May see if a local cabinet maker will take on the veneering if it is a reasonable cost, don't want to ruin $$$ veneer.

Room treatment, well some day.

I recently got a used Technics Sl-1500C with a Ortofon 2M Bronze that I also need to set up, last turntable I will ever need. My audio setup is a Purifi amp with NC500 buffers, Mini DSP SHD fed by the PC over USB, TV over optical (PS4), and Art DJPRE II Phono Preamplifier over RCA. Cables are the no frills Micca 14ga, they have a good tone to blend in with the brick hearth.

Pictured in their role as a new cat tree, and then with anti cat hole covers.

Veneer still to go, I have AAA Bolivian Rosewood raw wood which will be its own journey. I was going to vacuum bag and all that, but I think I may try heat application given the curvature I have to deal with. Need to get the workshop is good order before attempting that. Veneer is why the top edge isn't rounded, sides have a generous 1.5" roundover.

May see if a local cabinet maker will take on the veneering if it is a reasonable cost, don't want to ruin $$$ veneer.

Room treatment, well some day.

Why do you think there cannot be standing waves inside a loudspeaker enclosure?There are no standing waves inside a speaker box. SW might take place in a room, yes

I see the pictures, now, after log-in: what about putting the crossover out of the box ?! Still it's about box environment...

Now let's see the Xxx-over...what's that 3 Ω resistor in front of the woofer??Maybe better to take a look at Jshadzi's design!

- Home

- Loudspeakers

- Multi-Way

- 3 Way w/SB Acoustics Ceramics (woofer choice?)