You mention modulation. Each woofer should be handling the same signal at the same time, so isn't this something else?

It depends what you are referring to. The electrical signal itself, notwithstanding losses, is by definition the same, but different drive units, particularly dissimilar types, have their own balances of damping, resonance etc. To use the above example, I wouldn't be overly keen on running a rather delicate Lowther into the same shared box as, say, a large 12in woofer that has a different baseline sensitivity, resonant frequency &c., & I would have significant concern that that woofer, especially when the wick gets turned up, is going to exert an increasing influence in terms of internal pressures &c. over the smaller unit at some stage or other. While you can get away with it in some cases, as Thorsten, Wilson, Troels etc. have, with drivers of roughly analogous types, with larger variations I would expect to see that to break down a bit. YMMV as always of course.

Re the Elsinore Steve, it's a 2.5-way with the four units actually wired in series-parallel rather than purely in series (I did the series-parallel part myself with the Edingdale shown below, though the design is otherwise very different to the Elsinore).

Attachments

Last edited:

So if I understand this thread correctly, its supposed to address the non-uniform movement of multiple same type drivers connected in series vs parallel in a shared enclosure air space. The size, type of enclosure, driver diameter, suspension compliance, tuning frequency, etc will have alot of influence on this too.

My take is that a parallel connection of drivers would be more beneficial than series, mainly because both drivers are being directly controlled by the significantly lower output impedance of the amplifier, so the drivers are relatively immune from the eddy current of each other and therfore isolated from interacting.

Now if the pressure fluctuations from standing waves inside the enclosure are exerting alternating different forces on the backside of the driver cones, it could introduce some dynamic response abnormalities that modulate the collective total system output. It also can introduce rocking forces in the suspensions if the standing wave length is short enough (less than the distance of drivers to each other), relative to the shared enclosure dimensions and also accounting for location relative to internal enclosure boundaries as well as baffle placement symmetry. This can show itself as increased THD, especially around the Fb of a vented enclosure and frequencies lower than driver's own Fs.

In the case of drivers wired in series, there can be more serious consequences if the enclosure volume is fairly large and driver compliance is high, in which case the enclosure air volume has relatively little effect on total system compliance. In this scenario, the drivers can be prone to modulation between each other around Fb, especially if the drivers' TS parameters aren't well matched.

Along these lines, I once had a weird experience with a large acoustic suspension subwoofer with 4 x 12" drivers wired in series. Sometimes one or another driver individually and alternately would bottom out early only with certain music. After doing sine wave sweeps, it was determined that the drivers would interact with each other in a way that didn't distribute power evenly, mainly close to Fb. I could induce the problem if I lightly held one of the driver cones from free movement and it would lightly oscillate between the drivers, slowly dissipating most of the time. If I slightly varied the drive frequency around Fb, the drivers would alternately take off in amplitude and excursion would increase. On rare occasion I could get a modulating wave to circulate between all the drivers if I carefully honed in on the right frequency and amplitude. Very weird, but a potentially bad problem. The issue was fixed by combined series / parallel wiring of the drivers.

In regards to someone mentioning an issue with large cone drivers in vented cabs, I also can report some confirming observations about a problem with cone rocking. The issue was with an 18" ported cerwin vega sub that had a weird distortion behavior at certain frequencies. The VC would sound like it was rubbing and I could make it disappear when I put pressure on one side of the cone. I thought this was a bad driver, but I decided to reinstall the driver rotated by 180 degrees thinking it was cone sag. The VC was still rubbing, but this time it would go away when I pushed on the same area on the cone related to how it was installed in the enclosure, not the actual same place on the driver cone itself. The issue was uneven (unbalanced) backpressure across the entire cone surface itself caused by asymmetrical port location. The problem went away when I relocated the port to the center of the cab behind the driver. I think this issue would be more likely to crop up on higher compliance drivers with soft cones (as in the example of the older cerwin vega driver) and single spider suspensions. This likely one of the reasons why many large pro sound drivers have double spiders and lower compliance suspensions that suppress this sort of problem, especially with the tighter VC gaps and higher excursion levels they tend to run.

My take is that a parallel connection of drivers would be more beneficial than series, mainly because both drivers are being directly controlled by the significantly lower output impedance of the amplifier, so the drivers are relatively immune from the eddy current of each other and therfore isolated from interacting.

Now if the pressure fluctuations from standing waves inside the enclosure are exerting alternating different forces on the backside of the driver cones, it could introduce some dynamic response abnormalities that modulate the collective total system output. It also can introduce rocking forces in the suspensions if the standing wave length is short enough (less than the distance of drivers to each other), relative to the shared enclosure dimensions and also accounting for location relative to internal enclosure boundaries as well as baffle placement symmetry. This can show itself as increased THD, especially around the Fb of a vented enclosure and frequencies lower than driver's own Fs.

In the case of drivers wired in series, there can be more serious consequences if the enclosure volume is fairly large and driver compliance is high, in which case the enclosure air volume has relatively little effect on total system compliance. In this scenario, the drivers can be prone to modulation between each other around Fb, especially if the drivers' TS parameters aren't well matched.

Along these lines, I once had a weird experience with a large acoustic suspension subwoofer with 4 x 12" drivers wired in series. Sometimes one or another driver individually and alternately would bottom out early only with certain music. After doing sine wave sweeps, it was determined that the drivers would interact with each other in a way that didn't distribute power evenly, mainly close to Fb. I could induce the problem if I lightly held one of the driver cones from free movement and it would lightly oscillate between the drivers, slowly dissipating most of the time. If I slightly varied the drive frequency around Fb, the drivers would alternately take off in amplitude and excursion would increase. On rare occasion I could get a modulating wave to circulate between all the drivers if I carefully honed in on the right frequency and amplitude. Very weird, but a potentially bad problem. The issue was fixed by combined series / parallel wiring of the drivers.

In regards to someone mentioning an issue with large cone drivers in vented cabs, I also can report some confirming observations about a problem with cone rocking. The issue was with an 18" ported cerwin vega sub that had a weird distortion behavior at certain frequencies. The VC would sound like it was rubbing and I could make it disappear when I put pressure on one side of the cone. I thought this was a bad driver, but I decided to reinstall the driver rotated by 180 degrees thinking it was cone sag. The VC was still rubbing, but this time it would go away when I pushed on the same area on the cone related to how it was installed in the enclosure, not the actual same place on the driver cone itself. The issue was uneven (unbalanced) backpressure across the entire cone surface itself caused by asymmetrical port location. The problem went away when I relocated the port to the center of the cab behind the driver. I think this issue would be more likely to crop up on higher compliance drivers with soft cones (as in the example of the older cerwin vega driver) and single spider suspensions. This likely one of the reasons why many large pro sound drivers have double spiders and lower compliance suspensions that suppress this sort of problem, especially with the tighter VC gaps and higher excursion levels they tend to run.

But are you talking about new frequencies being created?It depends what you are referring to. The electrical signal itself, notwithstanding losses, is by definition the same,

You only mention resonance. Ok, the drivers feel each other. This happens whether they are balanced or not.

The problem went away when I relocated the port to the center of the cab behind the driver. I think this issue would be more likely to crop up on higher compliance drivers with soft cones (as in the example of the older cerwin vega driver) and single spider suspensions. This likely one of the reasons why many large pro sound drivers have double spiders and lower compliance suspensions that suppress this sort of problem, especially with the tighter VC gaps and higher excursion levels they tend to run.

Yes.

So in a case of high SPL eventually you actually hear the cone rocking making the voice coil rub.

Otherwise at low SPL just assume the uneven pressure is still there.

And contributes to overall distortion/ response of the speaker.

Then assume if this pressure was equalized. It would reduce

the distortion associated with it.

Single port in the middle made that happen. Or as mentioned

4 ports in each corner is a known method as well.

Of course you can make the speaker tougher

to deal with un even pressure.

But it just seems easy as well to use more

symmetrical porting in any speaker design

After I experienced the issue as well.

I figured regardless of home stereo / live sound

Any enclosure will have unequal pressure.

And as far as common reflex cabinets.

I tend to look at ways to equalize pressure

to hopefully reduce distortion.

"takes on the weakest driver"? Didn't follow that... 😕

Didn't find that terribly precise either... 😕

Now "Rocking Mode" I do know. Spider needs to be good.

Spider needs to be good, or as mentioned

4 ports total in each corner...or

Symmetrical porting/ speaker placement to equalize pressure.

Far as weakest driver in series. Easy Example would be

Say with a pair of speakers

if individual tested. One driver had more output/sensitivity than the other.

Since they are in series the weakest driver will always be dominant in the overall sound output.

As with any other electrical characteristic of a driver.

Its series.

Easy experiment is to take 2 dissimilar drivers, or even 2 matching drivers.

Where when listened to individually one has a noticeable lower output

or poor sound. Connected in series the overall sound will be of the poorest driver.

Its why I prefer parallel drivers.

Or of course in a extreme case especially with tube amps.

If one voice coil is /disconnected/ damaged / blown.

Since it is series you now have a no load situation.

Bad news with a tube amp.

I tend to use parallel wiring only for tube amps.

So its less likely to have a no load situation

with multiple matching drivers

Last edited:

I hate to sound curmudgeonly, but this is a tale of two modes:

Until we see some actual testing and measurement of voltages and currents with the two drivers, which will reflect the actual movement of two midbasses in a common enclosure, it's all just guesswork! 😀

The Maths is vaguely related to what we used to call common-mode and difference-mode in twisted pair telephone wires. A cheap but elegant solution.

Each pair of wires is designed to be fairly impervious to the signals on the other wires. Thus little crosstalk or interference between the telephone circuits.

Until we see some actual testing and measurement of voltages and currents with the two drivers, which will reflect the actual movement of two midbasses in a common enclosure, it's all just guesswork! 😀

The Maths is vaguely related to what we used to call common-mode and difference-mode in twisted pair telephone wires. A cheap but elegant solution.

Each pair of wires is designed to be fairly impervious to the signals on the other wires. Thus little crosstalk or interference between the telephone circuits.

I don't have a horse in this race because I no longer build vented box enclosures... but I recall from the distant past that when using dual woofers in a vented box, the best practice was: each woofer should have its own volume and its own vent. They should not share the volume or a common vent. I do not know from whom or where I got this guidance.

I haven't run into any issues with single chamber vented boxes that had 2 like LF drivers wired in parallel, given the tuning frequency was low enough and the box was on the larger side. I also built several 2.5 way floor standing designs with drivers wired in parallel and each driver being fed from separate sized inductors. I do tend to place the port(s) close to the LF drivers with both having similar distances to the port.

I have frequently run into problems with small ported 2 way speakers, mainly with excess midrange port output aggravated by higher box tuning frequencies. Ive come across some really weird anomalies there and its very hard to get a ported 2 way sounding clean in the lower mids, so I now usually build smaller 2 ways with sealed enclosures. They just sound much better to me that way and gel better with subs. I just use subs if I want more low end, rather than trying to muscle a lot of low end from smaller drivers that tend to flap in the breeze and even bottom out with turntable arm resonance.

I have frequently run into problems with small ported 2 way speakers, mainly with excess midrange port output aggravated by higher box tuning frequencies. Ive come across some really weird anomalies there and its very hard to get a ported 2 way sounding clean in the lower mids, so I now usually build smaller 2 ways with sealed enclosures. They just sound much better to me that way and gel better with subs. I just use subs if I want more low end, rather than trying to muscle a lot of low end from smaller drivers that tend to flap in the breeze and even bottom out with turntable arm resonance.

... its very hard to get a ported 2 way sounding clean in the lower mids

My experience exactly. I have great respect for those people who can build a really good small 2-way vented box. There are a lot of competing issues that have to be balanced and managed. I know it can be done, but I have not been able to do it, and now I have lost interest.

I also found that if the box tuning frequency is above ~32 Hz or so, the bass quality suffers... the bass performance is musically unsatisfying. A big vented box tuned to 24 Hz is very different than a small box tuned to 40 Hz.

j.

Smaller PR boxes tend to sound a bit lazier to me than ported ones. It could be the added mass of the PR vs the port. Then there's the limited linearity of the PRs suspension. I'm not saying it isn't doable, but a little more finicky to get right. You do have advantages at lower tuning frequencies where the port would be physically to long for the enclosure depth as well as avoiding the taller order pipe resonances.

Yes, and a PR limits the midrange sound leakage from inside the box. But there is still the fact that we have the box resonant tuning frequency right where bass instruments live.

I am just being a bit persistent here because I would like to know the answer to my ideas about two midbasses interacting in a common enclosure:

I think it's a hard problem. I am wary of jumping at it too quickly.

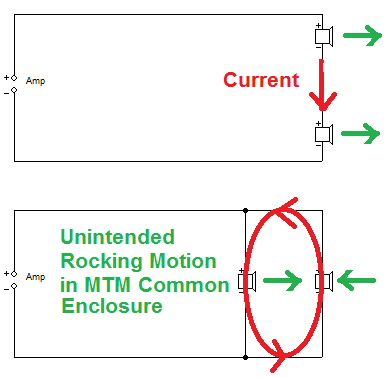

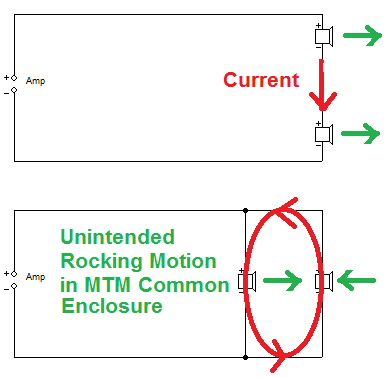

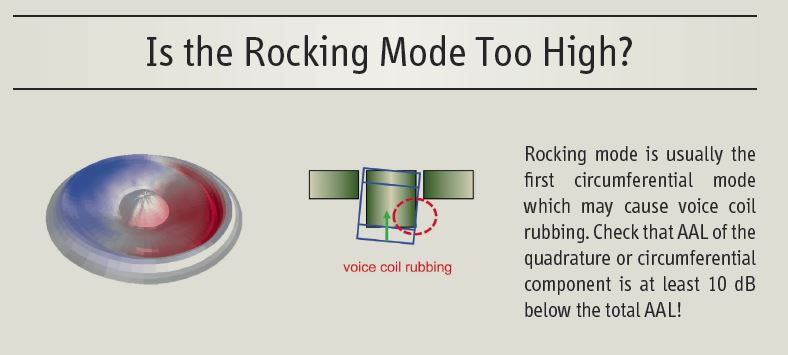

Talk about driver rocking mode isn't much to do with it, IMO:

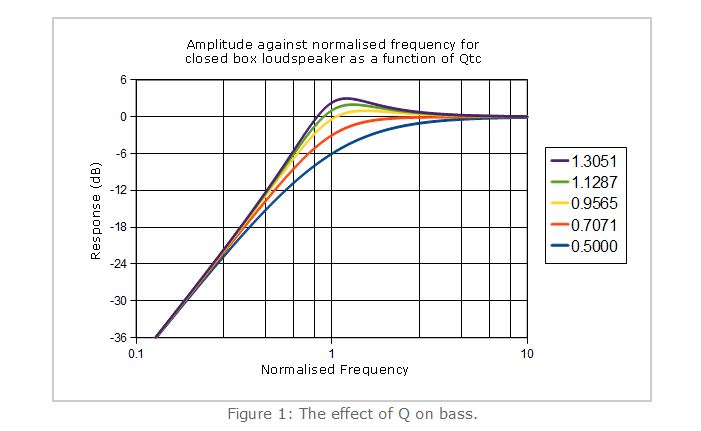

And bass calculations aren't really relevant. Closed box is just reflex at the limit of the port becoming tiny or passive radiator of infinite mass and stiffness:

I think it's a hard problem. I am wary of jumping at it too quickly.

Talk about driver rocking mode isn't much to do with it, IMO:

And bass calculations aren't really relevant. Closed box is just reflex at the limit of the port becoming tiny or passive radiator of infinite mass and stiffness:

I never liked that qtc box graph.

I always figured that the f9 is higher on a low qtc box

Speaker Box Enclosure Designer / Calculator Help

I always figured that the f9 is higher on a low qtc box

Speaker Box Enclosure Designer / Calculator Help

Attachments

TBH, I was always a bit puzzled with your rocking motion diagram Steve; AFAIK, rocking modes are usually taken, as Wolfgang Klippel puts it, to be '...small irregularities in the circumferential distribution of the stiffness, mass and magnetic force in the gap'. Assuming some kind of asymmetric physical force applied to one unit you may get some on compliance, & thereby on the current in the gap, but that would apply however the drivers were wired. An electrical energy transfer between mismatched units may cause problems, but whether any asymmetry in the VC gap would be a (or the) primary issue I wouldn't care to say.

I agree that the usual bass modelling calculations aren't likely to get very far in identifying where any issue may or may not occur WRT wiring the drivers, since they're lumped element methods assuming a fixed set of conditions, and we're in essence talking about the potential for problems when drivers depart from that. You can create compound set of T/S parameters to assess a nominal alignment for dissimilar units as Thorsten did, but I'd be wary if major differences existed in type as the mean may (to my perhaps mistaken logic) end up as risky for one of the units.

I agree that the usual bass modelling calculations aren't likely to get very far in identifying where any issue may or may not occur WRT wiring the drivers, since they're lumped element methods assuming a fixed set of conditions, and we're in essence talking about the potential for problems when drivers depart from that. You can create compound set of T/S parameters to assess a nominal alignment for dissimilar units as Thorsten did, but I'd be wary if major differences existed in type as the mean may (to my perhaps mistaken logic) end up as risky for one of the units.

Steve's usage of the term "rocking mode" is a bit unlucky but i don't know the correct term for the phenomenon either.

What he is talking of is the influence of one driver's pressure on the other one. If they are really equal then they will behave exactly the same as if they were both in seperate boxes of the same size. If their fb differs by a significant amount their excursion would not be equal around their individual fb and also force the other one to unwanted motions.

But I would say that the problem is worse with series connected drivers than parallel ones. With quality drivers having the same mileage one is most probably fine.

Regards

Charles

What he is talking of is the influence of one driver's pressure on the other one. If they are really equal then they will behave exactly the same as if they were both in seperate boxes of the same size. If their fb differs by a significant amount their excursion would not be equal around their individual fb and also force the other one to unwanted motions.

But I would say that the problem is worse with series connected drivers than parallel ones. With quality drivers having the same mileage one is most probably fine.

Regards

Charles

Last edited:

I don't know of one either, though I'm snowed under with work at present (hence not being around for a few days) so the brain isn't 100% on the old audio front. 😉 I suspect there isn't a specific term per se, though I speak under correction. Allen & GM are here & they haven't mentioned one, so I'm assuming that's likely the case.

Right, and that's certainly what I've been talking about, although I perhaps mistakenly assumed Steve really was referring to asymmetry in the circumferential distribution due to his graphics showing a laterally displaced coil &c.

Either way, I agree -with well-matched drivers, it's unlikely to be an issue for normal home use, and there are a reasonable number of examples. The Tritrix is one; the much-missed Jeff Bagby had another, and I recall Louis Coraggio had at least one on his site. Plenty of other speakers with a series-pair of units too, the Wavecor Ardent being a formidable (non-MTM) example. With poorly matched units I'd be a bit more careful though. Not that you want to be using a poorly matched set of drivers in the first place, but many aren't in a position to be able to measure & are at the mercy of the production QA / QC. Since we're living in an era when even some very well regarded companies (mentioning no names) only use a QA / QC production tolerance of 10% to Fs & nothing else, that's not so good. To be sure, unlikely to cause any terminal issues, but given the choice, I tend to favour parallel wiring for the reasons Lynn referred to as probably being a bit less vulnerable.

Right, and that's certainly what I've been talking about, although I perhaps mistakenly assumed Steve really was referring to asymmetry in the circumferential distribution due to his graphics showing a laterally displaced coil &c.

Either way, I agree -with well-matched drivers, it's unlikely to be an issue for normal home use, and there are a reasonable number of examples. The Tritrix is one; the much-missed Jeff Bagby had another, and I recall Louis Coraggio had at least one on his site. Plenty of other speakers with a series-pair of units too, the Wavecor Ardent being a formidable (non-MTM) example. With poorly matched units I'd be a bit more careful though. Not that you want to be using a poorly matched set of drivers in the first place, but many aren't in a position to be able to measure & are at the mercy of the production QA / QC. Since we're living in an era when even some very well regarded companies (mentioning no names) only use a QA / QC production tolerance of 10% to Fs & nothing else, that's not so good. To be sure, unlikely to cause any terminal issues, but given the choice, I tend to favour parallel wiring for the reasons Lynn referred to as probably being a bit less vulnerable.

Last edited:

I'm seeing three parts to this, and the first is the unequal division of the drive signal due to the differences in impedance. This attachment, an exaggerated example, shows that this alone doesn't prevent the total response from being flat.

The second part is the combination of the differences between the Q and frequency, and it's known that ordinarily combining nearby resonances produces a similar combined result that is probably not remarkable in itself in a case like this.

The third part is the way that unless the two drivers are working together, they no longer see the cabinet as half the volume at all frequencies.

Thus, assuming no higher modes are involved I think the individual drivers could be measured, for impedance and response, but it should be done while both are powered.. even if this means doing nearfield measurements. This should allow the sharing to be modelled and assessed. However if it is only for system design then the two could be measured as a unit.

The second part is the combination of the differences between the Q and frequency, and it's known that ordinarily combining nearby resonances produces a similar combined result that is probably not remarkable in itself in a case like this.

The third part is the way that unless the two drivers are working together, they no longer see the cabinet as half the volume at all frequencies.

Thus, assuming no higher modes are involved I think the individual drivers could be measured, for impedance and response, but it should be done while both are powered.. even if this means doing nearfield measurements. This should allow the sharing to be modelled and assessed. However if it is only for system design then the two could be measured as a unit.

Attachments

An update on my little project for those who gave me inputs to my question. The speakers are now build as inted. the two 4 ohms midbas i series, and a 8 ohm tweeter. The Cabinet volumen are build in 25mm MDF and a volumen around 48 litres. There are 4 ports in the bottum of the cabinets with an inner diameter on 46mm and a lenght on 270mm.

I'm still in "running in" process, and run them with an active DSP setup until they are ready for measuring to build a filter. The crossover frequency is now 2000Hz. I have tryed 2500Hz but that is not god, but middlerange is to "thin". I have tryed 1600Hz, and that is very simular to 2000, so it will end up somewhere between 1600 and 2000. Allthough the bass units have less than 20 hours there are desent bass, so i'm stille hopefull that I can succed with the project. So far I'm very happy.

I'm still in "running in" process, and run them with an active DSP setup until they are ready for measuring to build a filter. The crossover frequency is now 2000Hz. I have tryed 2500Hz but that is not god, but middlerange is to "thin". I have tryed 1600Hz, and that is very simular to 2000, so it will end up somewhere between 1600 and 2000. Allthough the bass units have less than 20 hours there are desent bass, so i'm stille hopefull that I can succed with the project. So far I'm very happy.

Attachments

Has anybody expirience with the 2 4 ohms midbass in Series, -and then in parallel with the High tone driver.

These:

With a passive XO you are looking for woofer sensitivity about 3dB more than the midTweeter.

dave

Last edited:

- Home

- Loudspeakers

- Multi-Way

- MTM Speaker drivers