I’ve been asked to see if I can fix hum in the output from 2 of 4 identical dual 300B SE amps.

The amps had been operating happily for a number of years before developing the hum.

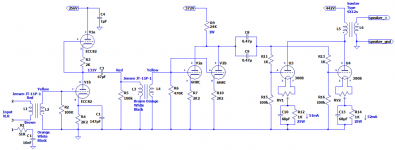

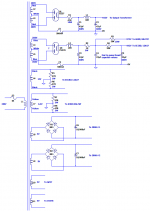

Attached are reverse-engineered schematics, an inside-chassis-shot and a screenshot of the output from my oscilloscope (the blue trace is one of the 5VAC heater supplies for reliable triggering).

Since the amps used to be OK and 2 of the 4 still are, I’ve been looking for changes that might have caused the problem.

First step was swapping all the tubes for those in a good amp. No joy.

Second step was fixing a couple of dry joints on an earth bus consisting of multi-stranded silver wire. I also checked all the joints in the amp. A couple on the 6H8C/6SL7GT) had no solder at all and I fixed those. Still no joy.

You can see ~11mV RMS of 50Hz on the output. I measured ~280mV of 100Hz ripple on the 2 HT supplies. I couldn’t measure any ripple on the 6SL7GT or 12AU7 supplies.

I attempted to simulate the HT supplies with PSUD2 and default Tx, inductor and capacitor resistances, but it insisted that the rectifier IFRM (current forward repetitive maximum) had been exceeded and wouldn’t give me a result. Maybe a user problem.

I’ve searched for threads on hum but those I’ve found all relate to hum encountered while building rather than after a long period of good operation.

Any suggestions as to how I should proceed please?

The amps had been operating happily for a number of years before developing the hum.

Attached are reverse-engineered schematics, an inside-chassis-shot and a screenshot of the output from my oscilloscope (the blue trace is one of the 5VAC heater supplies for reliable triggering).

Since the amps used to be OK and 2 of the 4 still are, I’ve been looking for changes that might have caused the problem.

First step was swapping all the tubes for those in a good amp. No joy.

Second step was fixing a couple of dry joints on an earth bus consisting of multi-stranded silver wire. I also checked all the joints in the amp. A couple on the 6H8C/6SL7GT) had no solder at all and I fixed those. Still no joy.

You can see ~11mV RMS of 50Hz on the output. I measured ~280mV of 100Hz ripple on the 2 HT supplies. I couldn’t measure any ripple on the 6SL7GT or 12AU7 supplies.

I attempted to simulate the HT supplies with PSUD2 and default Tx, inductor and capacitor resistances, but it insisted that the rectifier IFRM (current forward repetitive maximum) had been exceeded and wouldn’t give me a result. Maybe a user problem.

I’ve searched for threads on hum but those I’ve found all relate to hum encountered while building rather than after a long period of good operation.

Any suggestions as to how I should proceed please?

Attachments

Obvious question: you did try to re-adjust the hum suppressor trim pots?

These are things that may wander off with time.

Jan

These are things that may wander off with time.

Jan

So, RV1 and RV2 shown in the schematic are not there? Fixed resistors?

Yes then try with a 100R pot or so.

Jan

Yes then try with a 100R pot or so.

Jan

Check the cap and the bridge of the filaments of 300B

Normally, when I use the dc for 300B filaments in a stereo configuration, I use the opposite connection of them. In one 300B the + in one pin in the other tube on opposite. One-two time a year can swap the 300B so the consumption of filament is almost similar for both tubes.

Powering them with ac is always better

Walter

Normally, when I use the dc for 300B filaments in a stereo configuration, I use the opposite connection of them. In one 300B the + in one pin in the other tube on opposite. One-two time a year can swap the 300B so the consumption of filament is almost similar for both tubes.

Powering them with ac is always better

Walter

Yes, they are there. I'll try adjusting them. The 47Ω resistors are on the 6.3V and 12V supplies to the 6H8C and ECC82 respectively.

Each 300B has it's own rectified supply.Check the cap and the bridge of the filaments of 300B

Normally, when I use the dc for 300B filaments in a stereo configuration, I use the opposite connection of them. In one 300B the + in one pin in the other tube on opposite. One-two time a year can swap the 300B so the consumption of filament is almost similar for both tubes.

Powering them with ac is always better

Walter

Thanks Jan! Adjusting one of the 300B pots made no difference, adjusting the other 300B pot did!Obvious question: you did try to re-adjust the hum suppressor trim pots?

These are things that may wander off with time.

Jan

- Home

- Amplifiers

- Tubes / Valves

- Hum problem with a pair of old 300B SE amps