High Bl, strong motor strength is generally required.

Other parameters that make a driver "good" depend on how low, how loud, how clean, and how efficient you want the bass horn to be.

Other parameters that make a driver "good" depend on how low, how loud, how clean, and how efficient you want the bass horn to be.

Down to 20hz. How low, loud, clean, and efficient seems to be as much a function of the horn as the driver. I want it all.High Bl, strong motor strength is generally required.

Other parameters that make a driver "good" depend on how low, how loud, how clean, and how efficient you want the bass horn to be.

Here's what my novice horn knowledge tells me. High motor strength, strong and rigid cone, high efficiency. Xmax and Fs seem to be less important in horn drivers?

Dusty,Down to 20hz. How low, loud, clean, and efficient seems to be as much a function of the horn as the driver. I want it all.

Here's what my novice horn knowledge tells me. High motor strength, strong and rigid cone, high efficiency. Xmax and Fs seem to be less important in horn drivers?

Xmax determines clean (linear) output potential, so is as important in a horn as a direct radiator if you want maximum output potential from what would be a very expensive undertaking.

What SPL at 20 Hz do you want to achieve?

Hoping to achieve 115-120 db clean output with -3 at 20hz, with plenty of headroom to avoid distortion. Being inside the horn, I imagine 110db at 1 watt is not much of an ask. Speaking of which, has anyone taken measurements inside the mouth of a horn?Dusty,

Xmax determines clean (linear) output potential, so is as important in a horn as a direct radiator if you want maximum output potential from what would be a very expensive undertaking.

What SPL at 20 Hz do you want to achieve?

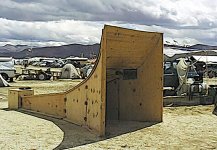

It really won't be that expensive, as I can do all the work myself and I would be using very cheap alternative building materials. The roof would would be the only part of the whole structure that would be pricey. If taking into account my labor, then yes, costly. The audio/video components would likely cost more than the structure.

The whole structure would probably be about 30' in length.20 hz from a horn? Just how large are you planning here?

Djk (rip) said xmax.....

Driver sensitivity didn't matter too much on a subwoofer horn.

https://db.audioasylum.com/mhtml/m....djk&r=&search_url=/cgi/search.mpl?forum=vinyl

Well i think mass corner for how high it goes b4 rolling still applies = (fs / qes) x 2

https://db.audioasylum.com/mhtml/m....djk&r=&search_url=/cgi/search.mpl?forum=vinyl

Driver sensitivity didn't matter too much on a subwoofer horn.

https://db.audioasylum.com/mhtml/m....djk&r=&search_url=/cgi/search.mpl?forum=vinyl

Well i think mass corner for how high it goes b4 rolling still applies = (fs / qes) x 2

https://db.audioasylum.com/mhtml/m....djk&r=&search_url=/cgi/search.mpl?forum=vinyl

Last edited:

how about one of those cheap Dayton 21" with relatively low Le ?

down at the bottom of the sims is a small mouth and corner loading

a mouth big enough to live in could take some wood - I see horrible pressure treated plywood at $87 a sheet and $67 for common OSB.

down at the bottom of the sims is a small mouth and corner loading

a mouth big enough to live in could take some wood - I see horrible pressure treated plywood at $87 a sheet and $67 for common OSB.

Attachments

In general, but depends on how high up you want it to load and how low the cutoff is; i.e. its upper mass corner as Norman noted. For instance the 14-120 Hz sim I did in the other thread required increasing the driver's Qts' from 0.33 to 0.833 otherwise HR wouldn't calc it.High Bl, strong motor strength is generally required.

Other parameters that make a driver "good" depend on how low, how loud, how clean, and how efficient you want the bass horn to be.

"You can't get there from here..." Fantasy horns show up here from time to time.... and never get built. Klipschorn is a wonderful room-filling sound and feels like great bass on almost all music, but poops out below 35 Hz.

But just in case, you also need to specify if there's going to be rear sealed chamber and if horn is direct enough to reach as high as mid-frequencies.

B.

But just in case, you also need to specify if there's going to be rear sealed chamber and if horn is direct enough to reach as high as mid-frequencies.

B.

- Home

- Loudspeakers

- Subwoofers

- What are the qualities of a good driver for driving a low bass horn?