I've read some threads about getting rid of resonance and standing waves

It seems ideal shape would be a sphere with a transmission line

If you are making a rectangular box and have limited machining/carpentry tools, what would be the best thing to do to help with resonance?

Would making side walls in triangle shape help?

Basically imitation of some b&w speakers where left and right wall of the speaker cabinet converge..so a horizontal cross section would look like a triangle more or less.

It seems ideal shape would be a sphere with a transmission line

If you are making a rectangular box and have limited machining/carpentry tools, what would be the best thing to do to help with resonance?

Would making side walls in triangle shape help?

Basically imitation of some b&w speakers where left and right wall of the speaker cabinet converge..so a horizontal cross section would look like a triangle more or less.

Make the inside dimension all multiples of 1.61 also known as golden ratio boxes (roughly 8/5) and linked to the Fibonacci sequence, fractals etc.

I.e. width 1.0, height 1.61, depth 0.62.

You can go further and space the drivers on the baffle using this ratio as well for distances from the top and side especially for the tweeter.

I.e. width 1.0, height 1.61, depth 0.62.

You can go further and space the drivers on the baffle using this ratio as well for distances from the top and side especially for the tweeter.

So my build involves midrange drivers and a tweeter in the middle.

Would making triangular enclosure like in attached scetch help?

Planning to put cross overs inside the rear triangle space created.

Thanks for Fibonacci tip.. this might be a more doable approach

Would making triangular enclosure like in attached scetch help?

Planning to put cross overs inside the rear triangle space created.

Thanks for Fibonacci tip.. this might be a more doable approach

Attachments

Or this little unparalleled shape would not make a huge difference. Just follow Fibonacci rule and stuff the speakers

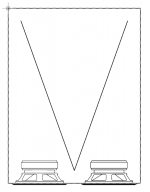

By putting non-parallel dividers in a rectangular box, you can easily break up the symmetry and thus avoid/reduce resonances or standing waves. For instance, if you join two thin boards to form a "V" and put the V in the rectangular box with the narrow end of the V pointing at the front baffle, the internal volume will be divided to look like a folded triangle. Adding absorptive materials (e.g., in the V) can attenuate reflected waves and further retard the generation of standing waves.

Kurt

Kurt

I just made a couple posts on the subject of outside shape: 3D printing enclosures without actual knowledge

Inside is a different thing. A sphere is one of the worst shapes for internal standing waves.

The affect of shape, inside & out, is different depending on what frequencies you are talking about.

A rule-of-thumb is that if you pass the unwanted back radiaiton, having it go thru a quarter-wavelength of damping material before being reflected. Of course how close depends on how effective the damping material is at the frequency of interest. A TL, quarter- or half-wave, damped until aperiodic is good for taming any internal air space resonances.

With sheet material having a box with significant chamfers can get really close to a more ideal shape.

With a loudspeaker in a room you are more interested in the horizontal than the vertical.

Trapezoidal with big chamfers:

Rectangular with large chamfers:

Cuboid shape (Classic Golden Ratio):

While none of these use the same driver (there exist literally hundreds of these with many different drivers), they illistate the difference in shape. The first speaker ia 2.5 litre, a variation of the same basic shape can be had up to 135 litres so far.

If we do take a set of these with the same driver, but of the set of 3 different shapes. Alignments are all the same. But with a reslving enuff system one can hear the difference. The extra effort of building the trapezoid pays off in a lousdpeaker with a lower diffraction signature, and a greater ability to “disappear”.

Here one can see how the trapezoid mimics a teardrop in the horizontal plane:

There is a lot more that can be said on the subject.

dave

Inside is a different thing. A sphere is one of the worst shapes for internal standing waves.

The affect of shape, inside & out, is different depending on what frequencies you are talking about.

A rule-of-thumb is that if you pass the unwanted back radiaiton, having it go thru a quarter-wavelength of damping material before being reflected. Of course how close depends on how effective the damping material is at the frequency of interest. A TL, quarter- or half-wave, damped until aperiodic is good for taming any internal air space resonances.

With sheet material having a box with significant chamfers can get really close to a more ideal shape.

With a loudspeaker in a room you are more interested in the horizontal than the vertical.

Trapezoidal with big chamfers:

Rectangular with large chamfers:

Cuboid shape (Classic Golden Ratio):

While none of these use the same driver (there exist literally hundreds of these with many different drivers), they illistate the difference in shape. The first speaker ia 2.5 litre, a variation of the same basic shape can be had up to 135 litres so far.

If we do take a set of these with the same driver, but of the set of 3 different shapes. Alignments are all the same. But with a reslving enuff system one can hear the difference. The extra effort of building the trapezoid pays off in a lousdpeaker with a lower diffraction signature, and a greater ability to “disappear”.

Here one can see how the trapezoid mimics a teardrop in the horizontal plane:

There is a lot more that can be said on the subject.

dave

By putting non-parallel dividers in a rectangular box, you can easily break up the symmetry and thus avoid/reduce resonances or standing waves.

Basically making it into a a member of the TL family. Complex is good for breaking up internal standing wave issues.

B&W DM302 from the late ‘70s.

This is not a TL, but a variable thickness backwall — a dramatic one.

Hegeman (handing off to Morrison) did seminal work on many small half-wave TLs built into the box to deal with bottom end resonances. Some recent posts on the subject goes into more detail on how to use it.

dave

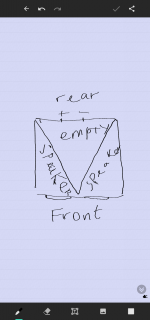

So basically a view from the top will look like this right?

Middle division wall is turned into a triangle

Forgive child looking drawings)

Yeah, you almost got it, but I'd make the V "shorter" and "narrower" so that the tip of the V does not hit the magnets of the drivers, and the open end of the V is not touching the back wall or the side walls. Think about it this way: the waves generated by the drivers will travel between the side walls and the V and then get reflected by the back wall into the inner volume of the V.

That is, of course, just one example. There are many ways, and I am sure some people can come up with some very complicated ways, to skin the cat.

Kurt

Last edited:

Triangles.

A design i origianlly did in the late ‘70s for the KEF B110/T27 kits we were selling and for the Fried H (Bud later borrowed the design): Pyramids

And the Tetra: High End Speakers-High End Studio Monitor Speakers-High End Reference Monitor Speakers-Surround Audio-Surround Sound Audio-Best Sounding Looks like they have abandoned the shape that gace the company its name.

dave

A design i origianlly did in the late ‘70s for the KEF B110/T27 kits we were selling and for the Fried H (Bud later borrowed the design): Pyramids

And the Tetra: High End Speakers-High End Studio Monitor Speakers-High End Reference Monitor Speakers-Surround Audio-Surround Sound Audio-Best Sounding Looks like they have abandoned the shape that gace the company its name.

dave

Attachments

Dave thank you for your posts. I've read some threads here that went into great details of dealing with standing waves..

A little beyond the scope of what I can do in my shop and my understanding of the matter at the moment.

I was looking for easiest trick to help with standing waves.also outside dimensions of the speaker needs to be rectangular to also work as a shelve) I live in new York..space must be used with utmost efficiency

A little beyond the scope of what I can do in my shop and my understanding of the matter at the moment.

I was looking for easiest trick to help with standing waves.also outside dimensions of the speaker needs to be rectangular to also work as a shelve) I live in new York..space must be used with utmost efficiency

So basically a view from the top will look like this right?

Better to not have the V attached to the walls. Then you can use the whole space to better effect. It creates a longer more complex half-wave TL. Stuff the pointy bit more densely. I like an aperiodic quarter-wave midTL for midTweeters (and midranges). An example at the end.

Note: you want the mids as close together as possible. Use a tweeter with a small bezel, or one that you can trim down to get the mids closer.

dave

Attachments

The simplest of these is to place damping material inside the box.

Good point, often more than good enuff. But the V could be used to dramatically brace the box walls… make the open bits in the V holes drilled into the V's panel wall to achieve the opening.

Going a bit oerboard is not a bad thng (usually).

dave

So basically the v inside is like a reflector/vent. The ends of the V are not attached to either wall? Basically just like on a. Image u attached.

Many years ago I built a subwoofer enclosure with an octagonal cross-section. When I hit the side of the enclosure, with the top open and without any damping material inside, it sounded like a drum! I placed a cushion with fake fur cover at the center of the enclosure, and it totally killed the resonance.

Kurt

Kurt

So basically the v inside is like a reflector/vent. The ends of the V are not attached to either wall? Basically just like on a. Image u attached.

It is more complex than that. How it acts depends on frequency. A bent is a “hole” loading to the outside (or to another box).

dave

I've read some threads about getting rid of resonance and standing waves

[...]

Would making side walls in triangle shape help?

Not really.

Much of this stuff is low frequency, where the wavelength is over 50cm long. That is large, relative to the size of any little lumps or wiggles you could put on the box.

Most designs that do this are simply trying to look good in their brochures / attempting to justify a high price tag.

If you do want to make the internal surfaces chaotic, just glue some random scraps and rubbish to the inside of your box. It will work exactly as well as $5000 worth of pretty translaminated CNC work.

It seems ideal shape would be a sphere with a transmission line

Good positioning + rounding the edges is enough.

The difference in quality between a "good" solution and an "ideal" solution is small, and there will usually be something else happening (room modes, or traffic noise or someone's dog barking incessantly) that is much more detrimental to your enjoyment than a 0.2dB wiggle in response.

If you are making a rectangular box and have limited machining/carpentry tools, what would be the best thing to do to help with resonance?

For a simple box, felt on the front baffle does approximately the same thing as rounding the baffle edges.

Usually composite material is better than monolithic materials. Cheap can beat $$.

e.g. laminated MDF is better than plain MDF.

A thin rigid box, heavily lined with whatever (lead, rubber, goo), works pretty well.

This has been tested by turntable nerds (lots of tests, which I can't find right now) and the BBC, see here:

plinth design and fabrication - audio qualia

The "polyester resin/kitty litter" combo (the best option listed) simply means the same sort of resin you'd use with fibreglass with clay mixed through it.

You could probably use any other glue + any other dense filler.

If I wanted to take this route, I'd probably use a thin skin of bamboo backed / braced with as the shell, with the faces held together via fairly beefy braces or glue blocks, coated on the inside with a thick layer of resin + clay goo.

I'd do it this way because bamboo is pretty, very hard wearing (scratch proof), not too expensive, and "better" than ply for damping / sound transmission.

To really streamline the build: Ikea sells some bamboo stuff that is good for repurposing as small speaker boxes.

You can use any tools for the glue + laminate step. If you don't have infinite clamps, but you do have 100kg of books or canned food or whatever, that will do.

Look up "constrained layer damping" if you want to dive deep into the topic. It has been discussed to death already by smarter people than me 🙂

Last edited:

For a simple box, felt on the front baffle does approximately the same thing as rounding the baffle edges.

Only at higher frequencies. And only edge diffraction. It would have to be very thick to mimic the chamfer son the full-on miniOnkens.

dave

"It would have to be very thick to mimic the chamfer son the full-on miniOnkens."

Those full-on speakers are probably very nice, but do not seem congruent with the original question:

"If you are making a rectangular box and have limited machining/carpentry tools, what would be the best thing to do to help with resonance?"

Those full-on speakers are probably very nice, but do not seem congruent with the original question:

"If you are making a rectangular box and have limited machining/carpentry tools, what would be the best thing to do to help with resonance?"

- Home

- Loudspeakers

- Multi-Way

- Ideal speaker shape to make at home