If the brown stuff washes off, it can be cap slime. If it stays put & becomes smoother lookiing, it is hot melt glue. Or possible rubber adhesive, a cool substance now banned by the California Air Board. *&^%#

After I was taking those pics I noticed how there is dark brown stuff all over the caps themselves, like a brush with brown goo rubbed up against them as they were trying to get down to the bottom of the cap. You can see it in the pics where stuff is speared all on the sides, it's the same color as the goo at the bottom. So I'm hoping that's all just some kind of glue.

No reason to put glue on the sides of the cap. Just around the bottom to hold a big cap to the board. If it ran down the sides, it probably leaked from the top. Wash it off and see what the towel looks like. Stain on the towel, cap slime.

No reason to put glue on the sides of the cap. Just around the bottom to hold a big cap to the board. If it ran down the sides, it probably leaked from the top. Wash it off and see what the towel looks like. Stain on the towel, cap slime.

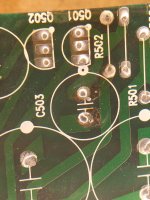

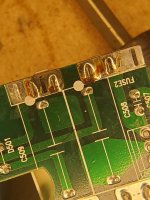

Here is a couple pics, one showing what I mean about the stuff smeared all over the side of the cap and where it looks like that stuff is kind of puddled up on the board. Also have a close up of the damaged area...I blew it up under my 'dental light' (I use it for car chip repair) to see the damage a bit closer.

The stuff on the side of the cap doesnt easily come off, I used alcohol on it prior to taking these pics.

Attachments

I also took some pics of the boards bottom, that smallish blue cap with all the brown smeared on it side next to all the damage, looks different that everything else on the bottom....also the bottom of fuse looks different too, like it got real hot or something (both fuses blew but only one has this brownish look to the solder).

Does any of that look like something that cant be repaired?

Does any of that look like something that cant be repaired?

Attachments

Try the amp as is. No necessary need to change the power supply caps.

The 2200ii sounds great as is, I enjoy it....but I thought with the modifications floating around online that it would sound even better. Do you think the difference is so minor that it's not worth the effort?

I bought two...one that I'm enjoying and one with a issue I'm bugging everyone here about, trying to fix it....but it's the one I thought I might modify since I'm having to repair it anyway.

But hell, your the designer, if you say the modifications wont make any difference then I'll just drop all that, patch it up and be done.

Last edited:

I also took some pics of the boards bottom, that smallish blue cap with all the brown smeared on it side next to all the damage, looks different that everything else on the bottom....also the bottom of fuse looks different too, like it got real hot or something (both fuses blew but only one has this brownish look to the solder).

Does any of that look like something that cant be repaired?

Around the caps and fuses looks like they didn't wash all the flux off.

99% alcohol is not the best solvent for water based compounds like in electrolytic caps. 409, scrubbing bubbles, fantastik, the new spray spicnspan are great. 70% isoprophyl alcohol is better , available for $1 at dollar tree. Or if stuck at home, water & dish detergent.

99% alcohol is not the best solvent for water based compounds like in electrolytic caps. 409, scrubbing bubbles, fantastik, the new spray spicnspan are great. 70% isoprophyl alcohol is better , available for $1 at dollar tree. Or if stuck at home, water & dish detergent.

Sounds good

I had it diluted down but prob more like 50%. It cleaned stuff off but not that stuff smeared on the side and bottom of the cap. But I'll grab some 409 or bubbles.

But what do you think that mess is in the pics of the sides of the cap, where it shows it smeared all over it?

Last edited:

C503 is a 1000 uf 100 v cap used to stabilize the current limiter q501. Not an expensive cap. I'd replace it.

You can check the health of the expensive rail caps with a watts test. Discontinued Products > HCA-2200II 2 Channel Amplifier

says watts/channel is 250 into 8 ohm, 385 into 4 ohms. You could buy four D100k1r0 1 ohm 100 w resistors for $11 each from electronicsurplus.com, series hook them up, put on stands to keep from burning the floor, and do a watts test. play the radio, turn up the volume, measure the voltsAC on the 4 resistors. P=(V^2)/z where z would be 4 ohms. Watts = spec, your rail caps don't have a problem.

You can check the health of the expensive rail caps with a watts test. Discontinued Products > HCA-2200II 2 Channel Amplifier

says watts/channel is 250 into 8 ohm, 385 into 4 ohms. You could buy four D100k1r0 1 ohm 100 w resistors for $11 each from electronicsurplus.com, series hook them up, put on stands to keep from burning the floor, and do a watts test. play the radio, turn up the volume, measure the voltsAC on the 4 resistors. P=(V^2)/z where z would be 4 ohms. Watts = spec, your rail caps don't have a problem.

Theres some write ups online that talk about doing that....based on some John Curl comments.... here is a write up about it.... whatishifi: Restoring and modifing a Parasound HCA-2200II power amp.

But attached is a mod writeup from Big Sky Audio, after he retired he posted what his modifications were. But I dont yet know enough about all this to tell if the web link how to and this attached document are the same or not....

Second, make sure that your feedback resistors (47K) are 1/2W Resista or Holco (old), nothing else will do.

So, the feedback resistor should be a special resistors exclusively made for audio !? Hmm...

.... sounds like typical audiophoolery. My crystal ball says that a 'common' 1/2 metal-film resistor will do the job.

.... sounds like typical audiophoolery. My crystal ball says that a 'common' 1/2 metal-film resistor will do the job.

Last edited:

C503 is a 1000 uf 100 v cap used to stabilize the current limiter q501. Not an expensive cap. I'd replace it.

You can check the health of the expensive rail caps with a watts test. Discontinued Products > HCA-2200II 2 Channel Amplifier

says watts/channel is 250 into 8 ohm, 385 into 4 ohms. You could buy four D100k1r0 1 ohm 100 w resistors for $11 each from electronicsurplus.com, series hook them up, put on stands to keep from burning the floor, and do a watts test. play the radio, turn up the volume, measure the voltsAC on the 4 resistors. P=(V^2)/z where z would be 4 ohms. Watts = spec, your rail caps don't have a problem.

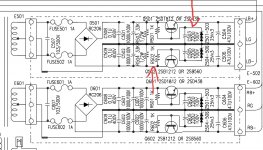

I'm waiting on tools to get here but in the meantime I was going over what you said and just want to verify it. I attached some images and this section of the schematic. Now on the bottom of the board the one that looks messed up around its solder is C503 (like you mentioned) but its a smaller 220uf/100v cap. The resister on top that looks all crispy is R502 and looking at board bottom C503 and R502 appear to be connected together.

I dont know much about this stuff but thought maybe a picture I'd posted made it C503 was the bigger 1000uf cap, but it's actually one of the smaller ones. It looks like C501 and C502 are the 1000uf caps.

So just wanting to make sure if you were suggesting C503 or if you meant C501 or C502 since they are the 1000uf caps.

Also, if you meant the c503 220uf/100v (which I think you did). Would you also replace that small crispy resister R502? If so, should I look for anything special regarding thier replacements? Should I replace the same ones on the right channel so they have the same parts, or will this not affect sound?

Attachments

Last edited:

You might want to find out why that resistor got crispy. Make sure Q502 and C506 are healthy, and the zener diode stack too (those would either be shorted or good). How many ohms does R502 *measure* now? Maybe somebody before you put in one too small? The amp may still *work* to some degree, even if that low current regulated supply is wonky. If it’s output voltage is too low, you’ll clip early and if it’s just putting out full unregulated voltage the only obvious symptom might be hum from power supply ripple.

You said some cap had brown debris on it that you didn't know if it was cap slime or glue. Doesn't look like glue to me. I'd replace it in a 20 year old amp without even thinking about it. A 220 uf cap would be even cheaper than a 1000 uf cap, $.30 instead of $.80. That resistor with brown **** on it, I'd replace that too. Per wg-ski's comment, check the resistor value and the load resistance before you order. I've had some Hammond organ amps burn a resistor in all three products I own that had the same amp. Bad design, I upgraded the wattage from 1 to 3.

Actually if an amp sounds funny, is too polite with no volume peaks, or won't pass a full watts test on resistors, I replace all the e-caps anyway. If one replaces only "the one that is bad" the amp is broken all the time as caps fail one by one. The amps I leave old caps in are closet queens that had a bad solder joint that made them unreliable from day one. 25 year old caps in Peaveys that have only a dozen hours use or so are fine. The same can't be said of consumer trash caps that come in low end TV's, converter boxes, replacement ATX supplies from the local shop, or similar trash products.

I make some bad solder joints so I don't replace every cap at once without testing function. If you replace 2 and the amp gets worse on test, you have a real good idea without much debug where the problem is. I'm lucky the amps I work on will work with the cover off in all cases.

Actually if an amp sounds funny, is too polite with no volume peaks, or won't pass a full watts test on resistors, I replace all the e-caps anyway. If one replaces only "the one that is bad" the amp is broken all the time as caps fail one by one. The amps I leave old caps in are closet queens that had a bad solder joint that made them unreliable from day one. 25 year old caps in Peaveys that have only a dozen hours use or so are fine. The same can't be said of consumer trash caps that come in low end TV's, converter boxes, replacement ATX supplies from the local shop, or similar trash products.

I make some bad solder joints so I don't replace every cap at once without testing function. If you replace 2 and the amp gets worse on test, you have a real good idea without much debug where the problem is. I'm lucky the amps I work on will work with the cover off in all cases.

Last edited:

"old" gear = spring(s) with no bounce (left)

I have maintained from day one... re-cap, to eliminate variables *Not opposing John, not saying all are bad. The images support the fact something IS unhappy and needs addressing. The portion of this scenario, I struggle with most [in my own gear] is the prospect of component failures that take out other parts with them. **Not to mention, simply limiting long term listening enjoyment.

It seems many people *marvel* their "old" / vintage gear because it often sounds soft(er) and woolly, maybe more "forgiving" **To me [analogy] like a vintage wine, with the tannin's and flavor structure profile changing with time. Some good, some bad, some (times) vinegar. There is a lot of "sour" gear out there, people do not realize it. Sour = so so, really quite mediocre [as it sits] this will offend some people.

The approach of using the "parts list" from *the mod 'group'* you PM'd me SPO, to choose electrolytic caps, exact parts, values and manufacturers... EG. use a known recipe, don't try and re-invent the recipe, screw up a good thing. The 2200 IS worthy of the work over time, as you can do it... using good parts.

Frankly, (I believe) the splatter / burn mark on the resister is a result of an insect vaporizing in an unfortunate mis-step... saw this often the repair shop I used to work...

Well said!Actually if an amp sounds funny, is too polite with no volume peaks, or won't pass a full watts test on resistors, I replace all the e-caps anyway. If one replaces only "the one that is bad" the amp is broken all the time as caps fail one by one...

I have maintained from day one... re-cap, to eliminate variables *Not opposing John, not saying all are bad. The images support the fact something IS unhappy and needs addressing. The portion of this scenario, I struggle with most [in my own gear] is the prospect of component failures that take out other parts with them. **Not to mention, simply limiting long term listening enjoyment.

It seems many people *marvel* their "old" / vintage gear because it often sounds soft(er) and woolly, maybe more "forgiving" **To me [analogy] like a vintage wine, with the tannin's and flavor structure profile changing with time. Some good, some bad, some (times) vinegar. There is a lot of "sour" gear out there, people do not realize it. Sour = so so, really quite mediocre [as it sits] this will offend some people.

The approach of using the "parts list" from *the mod 'group'* you PM'd me SPO, to choose electrolytic caps, exact parts, values and manufacturers... EG. use a known recipe, don't try and re-invent the recipe, screw up a good thing. The 2200 IS worthy of the work over time, as you can do it... using good parts.

Frankly, (I believe) the splatter / burn mark on the resister is a result of an insect vaporizing in an unfortunate mis-step... saw this often the repair shop I used to work...

case of another 20+ y.o. amp

**Not to thread jack** strictly, to illustrate a point, alluding so many??

I just re-capped my Audio Research VT-200. Every main PS cap,

measured nearly the same, strangely about 10% below rated value.

The 20 original caps ALL tested very consistent, test "as well".

ALL CAPS FAILED, in terms of internal resistance,

the actual health of these caps, they WERE ALL DEAD!

The values all over the place, none were the same.

**Not to thread jack** strictly, to illustrate a point, alluding so many??

I just re-capped my Audio Research VT-200. Every main PS cap,

measured nearly the same, strangely about 10% below rated value.

The 20 original caps ALL tested very consistent, test "as well".

ALL CAPS FAILED, in terms of internal resistance,

the actual health of these caps, they WERE ALL DEAD!

The values all over the place, none were the same.

Last edited:

When I was working on an HCA1000, I didn’t get much out of changing the feedback resistors myself, and it wasn’t easy to find those special ones either…

The parts swapped in servo made more difference by far.

The parts swapped in servo made more difference by far.

You said some cap had brown debris on it that you didn't know if it was cap slime or glue. Doesn't look like glue to me. I'd replace it in a 20 year old amp without even thinking about it. A 220 uf cap would be even cheaper than a 1000 uf cap, $.30 instead of $.80. That resistor with brown **** on it, I'd replace that too. Per wg-ski's comment, check the resistor value and the load resistance before you order. I've had some Hammond organ amps burn a resistor in all three products I own that had the same amp. Bad design, I upgraded the wattage from 1 to 3.

Actually if an amp sounds funny, is too polite with no volume peaks, or won't pass a full watts test on resistors, I replace all the e-caps anyway. If one replaces only "the one that is bad" the amp is broken all the time as caps fail one by one. The amps I leave old caps in are closet queens that had a bad solder joint that made them unreliable from day one. 25 year old caps in Peaveys that have only a dozen hours use or so are fine. The same can't be said of consumer trash caps that come in low end TV's, converter boxes, replacement ATX supplies from the local shop, or similar trash products.

I make some bad solder joints so I don't replace every cap at once without testing function. If you replace 2 and the amp gets worse on test, you have a real good idea without much debug where the problem is. I'm lucky the amps I work on will work with the cover off in all cases.

Do you have any experience with Wurth caps? Are they good caps? They are rated for 125C and life span over 2000hrs at max temp and voltage, of course I will never play this at its max. Would there be any sonic difference in using a different brand cap or one marketed to audio?

I'm asking because I found someone who repairs a lot of electronics and modifies them and has test equipment and such. I talked to him and he uses a lot of Wurth caps....I'm thinking about taking them amps to him so I dont risk messing them up. But wondering about these caps he would be using.

Last edited:

I just bought some wurth caps rated 5000 hours 105 c or 7000 hours 105c. They were stocked by Newark (farnell) who I have found in the past carries no garbage. I haven't installed any yet, but I expect no problems.

The 1000 hour caps Newark stocks, are consistant. They will last 1000 hours 85 C or, in my experience, 6 to 8 years in 2000 hour a years service. I don't buy those because I don't care to do the re-e-cap job every 8 years as I did 4 times on my ST-70. I buy 5000 hour caps because I want to do the job once and enjoy it the rest of my life.

The 1000 hour caps Newark stocks, are consistant. They will last 1000 hours 85 C or, in my experience, 6 to 8 years in 2000 hour a years service. I don't buy those because I don't care to do the re-e-cap job every 8 years as I did 4 times on my ST-70. I buy 5000 hour caps because I want to do the job once and enjoy it the rest of my life.

Last edited:

I just bought some wurth caps rated 5000 hours 105 c or 7000 hours 105c. They were stocked by Newark (farnell) who I have found in the past carries no garbage. I haven't installed any yet, but I expect no problems.

The 1000 hour caps Newark stocks, are consistant. They will last 1000 hours 85 C or, in my experience, 6 to 8 years in 2000 hour a years service. I don't buy those because I don't care to do the re-e-cap job every 8 years as I did 4 times on my ST-70. I buy 5000 hour caps because I want to do the job once and enjoy it the rest of my life.

Great, sounds like good caps then. I was looking at this page on thier website and they have several types of electrolytic capacitors. One is "low impedance"....is there any kind of benifit in audio to using low impedance caps?

Radial THT | Passive Components | Wurth Elektronik Product Catalog

Also based on thier data, the 125c rated caps will have a very very long lifespan when used at temps less than 125c, so it sounds like he would be using very long life caps.

Last edited:

- Home

- Amplifiers

- Solid State

- Is a Parasound HCA-2200ii still reliable?