Hi Members.

I'll be soon re clothing the speaker covers of my B&W DM110's.

The frames a plastic of some sort and I have regular speaker cloth.

My brief is to successfully glue the cloth to the frame at minimal cost, & I want to avoid staples

What type of glue can I use?

I have Crafters Choice Tacky Craft Glue, & Selleys PVA glue.

Are these suitable?

.

Thanks.

I'll be soon re clothing the speaker covers of my B&W DM110's.

The frames a plastic of some sort and I have regular speaker cloth.

My brief is to successfully glue the cloth to the frame at minimal cost, & I want to avoid staples

What type of glue can I use?

I have Crafters Choice Tacky Craft Glue, & Selleys PVA glue.

Are these suitable?

.

Thanks.

Last edited:

You need an instant contact adhesive such as Evo Stik Impact.

Same procedure as outlined in post #12 here: https://www.diyaudio.com/forums/con...e-grille-cloth-wood-grille-2.html#post6795981

Same procedure as outlined in post #12 here: https://www.diyaudio.com/forums/con...e-grille-cloth-wood-grille-2.html#post6795981

Thanks.

Will give it a go.

I might try a comparable local product, if Evo Stik is a European thing?!

Will give it a go.

I might try a comparable local product, if Evo Stik is a European thing?!

Synthetic rubber solution can attack some plastics.

Try a small patch first.

Or use hot melt glue.

PVA may not be strong enough.

Try a small patch first.

Or use hot melt glue.

PVA may not be strong enough.

Evo Stik is a trade name, Cliff - just look for a "contact adhesive".

P.S. Strangely, the grille frames on my DM110s are wood composite. However, contact adhesive is still applicable.

P.S. Strangely, the grille frames on my DM110s are wood composite. However, contact adhesive is still applicable.

Evo Stik = Rubber solution, honey colored stuff, used as shoe adhesive (among other uses).

Don't buy too much, it gets spoiled once exposed to air.

Let it get tacky, 10 minutes, then press both parts together.

Don't buy too much, it gets spoiled once exposed to air.

Let it get tacky, 10 minutes, then press both parts together.

I've got a tin of contact adhesive.

I'll try it out.

It can get pretty messy, so I'll work it with care.

I'll try it out.

It can get pretty messy, so I'll work it with care.

That is done be a machine in a factory, the fabric is melted and pressed in the same cycle.

Difficult to do by hand without some way of holding the stretched fabric.

It is modified hot staking.

A common example is razor blade cartridges, the front and back are molded separately, and the parts joined after blade insertion by melting and pressing the projections.

Similar to hot riveting in a way.

Difficult to do by hand without some way of holding the stretched fabric.

It is modified hot staking.

A common example is razor blade cartridges, the front and back are molded separately, and the parts joined after blade insertion by melting and pressing the projections.

Similar to hot riveting in a way.

I think the equipment needed to hot melt the fabric would be more suitable for re clothing large numbers of grills.

You will need a fixture for each design of grill. And need to do hundreds a day.

Don't think on that path.

Don't think on that path.

More than European, it´s British!!!!😱Thanks.

Will give it a go.

I might try a comparable local product, if Evo Stik is a European thing?!

faithful Subjects of the Queen should also have it at home 😀

Hey, even WE have it in Argentina 😱

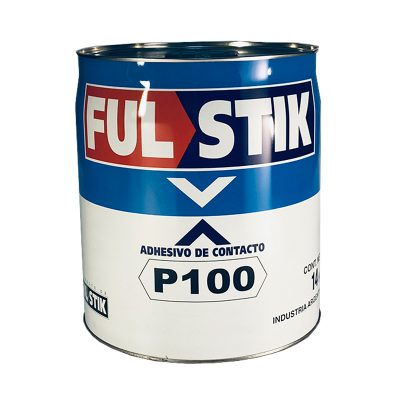

Only for some trademark issue here it´s called Ful Stik.

Very good contact adhesive, I buy it by the 5 Gallon cans to, precisely, Tolex my Guitar cabinets and grill cloth :cool

Or, if you hail from Argentina, adhesivo de contacto! 😛You need an instant contact adhesive...

Oh, the stuff inside the can is always the same 🙂

Sometimes we had exact same product under 3 different brands: Ful-Stik (locally made); Evo-Stik (UK made) and Bostik (guess it was US made) 🙄

Oh, for:

Sometimes we had exact same product under 3 different brands: Ful-Stik (locally made); Evo-Stik (UK made) and Bostik (guess it was US made) 🙄

Oh, for:

you must buy Xylene or Toluene (if legal in your Country) or same brand "contact cement solvent" and squirt a little inside the can before placing the cover back, which MUST fit tightly.Don't buy too much, it gets spoiled once exposed to air.

Originally originating in the USA, Bostik is now in the hands of the French company Arkema.Bostik (guess it was US made)

And Evo-Stik is a trademark of Bostik!

To help answer questions about compatability with grille frames and cloth, here is information from the Evo-Stik Impact Contact Adhesive Fact Sheet:

EVO-STIK Impact Adhesive is ideal for bonding wood, MDF, laminate, metal, PVC, cork, leather, rubber, glass, mirror, stone and ceramics.

EVO-STIK Impact Adhesive is not suitable for use on polystyrene, cellulose paint, vinyl, polythene, polypropylene and rayon fabrics.If in doubt, test a small area first.

- Home

- Design & Build

- Construction Tips

- Advice on recovering cloth on synthetic grill frames?