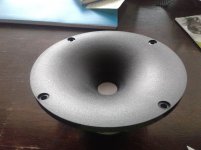

Thanks for everyone's replies to my last few posts about horns and compression drivers. I have another one. Looking at 2 horns with the same specs but very different looks. The Dayton H6512 and Eminence SST-1.

Dayton Audio - H6512 6-1/2" x 12" Waveguide 1" Threaded

https://www.eminence.com/speakers/hornflare-detail/?model=SST1

The H6512 is very rounded while the SST-1 is "flat-sided". I am wondering how this affects the sound.

Secondly, if the flat side design works well would anyone have a design to build this by laser cutting thin pieces of wood so they could be assembled into a horn (like a 3D puzzle)?

Dayton Audio - H6512 6-1/2" x 12" Waveguide 1" Threaded

https://www.eminence.com/speakers/hornflare-detail/?model=SST1

The H6512 is very rounded while the SST-1 is "flat-sided". I am wondering how this affects the sound.

Secondly, if the flat side design works well would anyone have a design to build this by laser cutting thin pieces of wood so they could be assembled into a horn (like a 3D puzzle)?

Every edge creates a reflection (echo), so i like the top one better.

Diffraction horns can sound very "live" adding a pleasant addition to the music.

Ideally, so diffraction slot, no edges, no corners, round over all the way to the baffle, and not very deep.

Diffraction horns can sound very "live" adding a pleasant addition to the music.

Ideally, so diffraction slot, no edges, no corners, round over all the way to the baffle, and not very deep.

Attachments

Every edge creates a reflection (echo), so I like the top one better.

Diffraction horns can sound very "live" adding a pleasant addition to the music.

Ideally, so diffraction slot, no edges, no corners, round over all the way to the baffle, and not very deep.

This is what I thought. And since they are injection molded there is no reason not to!