Should there be any difference if you tack your stuffing wool to the walls, or you could randomly leave them in the space you need.

Of course it makes sense that by tacking, you can force smash the stuffing, hence increasing its density.

Of course it makes sense that by tacking, you can force smash the stuffing, hence increasing its density.

I suppose it depends on the type of enclosure.

I would staple the likes of BAF wadding to the walls of a reflex enclosure, but fill a sealed enclosure with loose rolls of the stuff.

I would staple the likes of BAF wadding to the walls of a reflex enclosure, but fill a sealed enclosure with loose rolls of the stuff.

It all depends on alot of factors. Type of enclosure, LF driver crossover point, target system Q, preference in low end response or trying to clean up midrange leakage from the port. Proper cabinet construction goes a long way to avoiding the use of band aids, trying to fix it with dampening.

On a reflex enckosure, the goal is keeping the high air velocity pathway and zones close to the port and rear of LF driver free of any dampening material that will hinder efficiency, reducing LF output. Ported boxes are hard to get right and you risk overly tubby sounding mid bass along with midrange leaking from the port with not enough or improper damping materials placed in the wrong areas. You just have to experiment with what sounds best to you and satisfies your taste.

The type of damping material really can make a big difference and combinations of materials sometimes help strike a good compromise. In general I prefer rock wool on the walls of ported cabs to reduce lower midrange wash on a 2 way system. On a larger ported pro audio cab I usually prefer dacron stapled to the walls with extra layers behind the LF driver.

Sealed boxes usually get a combination of dacron and loose sheeps wool filling the majority of the enclosure depending on target system Q and type of driver used. Sheeps wool is my favorite in sealed enclosures and really good at wide band absorption while not sucking all the life out of the low end. If the total Q is too high, I resort to a higher percentage of mineral wool, but you run the risk of overdamping it and killing too much lower end output and detail.

With fiberglass or mineral wool I will use grille cloth to cover the LF driver basket and protect the moving parts, especially if it has exposed VC windings. You dont want fiberglass or mineral wool fibers to get into that area.

On a reflex enckosure, the goal is keeping the high air velocity pathway and zones close to the port and rear of LF driver free of any dampening material that will hinder efficiency, reducing LF output. Ported boxes are hard to get right and you risk overly tubby sounding mid bass along with midrange leaking from the port with not enough or improper damping materials placed in the wrong areas. You just have to experiment with what sounds best to you and satisfies your taste.

The type of damping material really can make a big difference and combinations of materials sometimes help strike a good compromise. In general I prefer rock wool on the walls of ported cabs to reduce lower midrange wash on a 2 way system. On a larger ported pro audio cab I usually prefer dacron stapled to the walls with extra layers behind the LF driver.

Sealed boxes usually get a combination of dacron and loose sheeps wool filling the majority of the enclosure depending on target system Q and type of driver used. Sheeps wool is my favorite in sealed enclosures and really good at wide band absorption while not sucking all the life out of the low end. If the total Q is too high, I resort to a higher percentage of mineral wool, but you run the risk of overdamping it and killing too much lower end output and detail.

With fiberglass or mineral wool I will use grille cloth to cover the LF driver basket and protect the moving parts, especially if it has exposed VC windings. You dont want fiberglass or mineral wool fibers to get into that area.

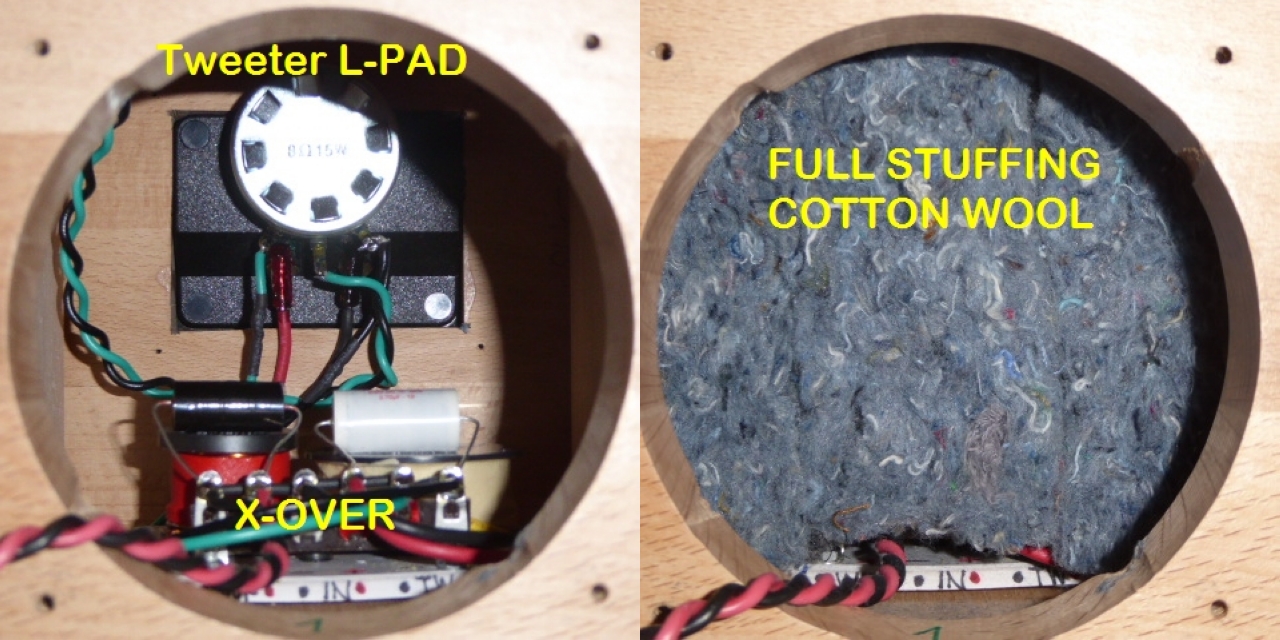

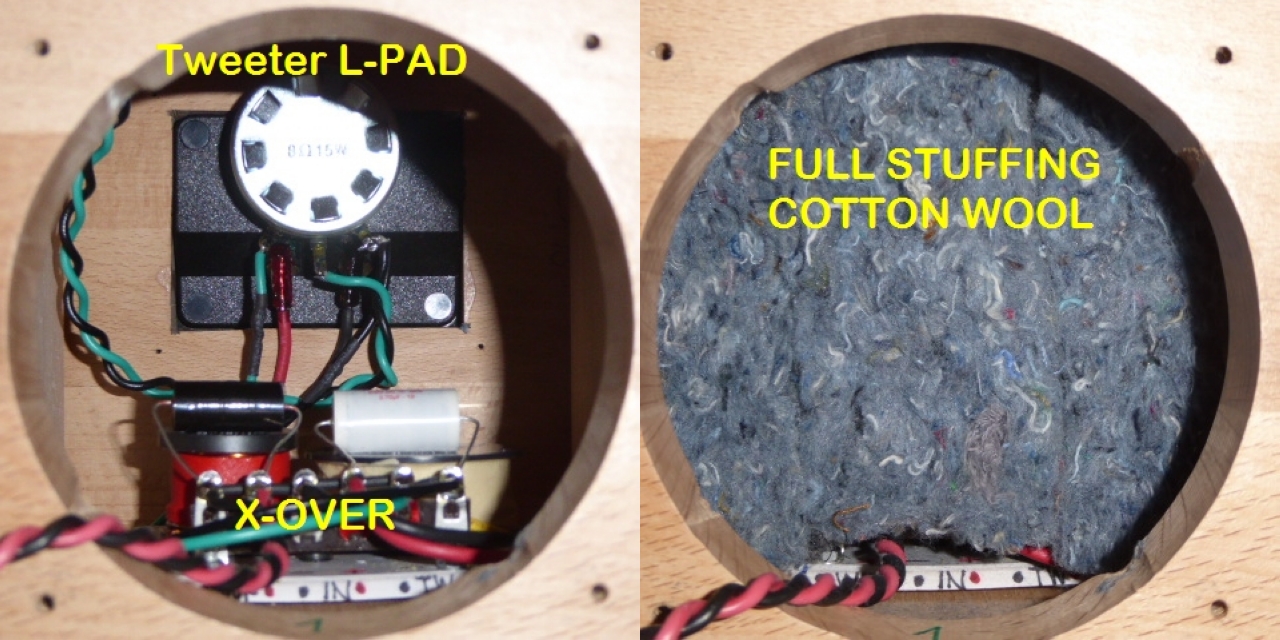

Personally, I fill nearly completely the volume of my enclosures, being bass-reflex or sealed type :

I use Cotton wool matress.

A+!

I use Cotton wool matress.

A+!

Those fan grilles are kind of a cool look. Is that damping material like a kind of recycled cotton padding?

To be clear, adding damping has an effect on the effective internal volume, so if you are wondering whether you need more or less, measure the bass output. 🙂

Those fan grilles are kind of a cool look. Is that damping material like a kind of recycled cotton padding?

Thanks @profiguy !

That's it : recycled cotton wool padding, used for home therma insulation. Harmless and excellent damping material.

A+!

To be clear, adding damping has an effect on the effective internal volume, so if you are wondering whether you need more or less, measure the bass output. 🙂

Yes, damping effect usually lowers a bit the resonant frequency of the enclosure, often providing an increase of acoustic volume equivalent to circa +15% in physical volume unstuffed that would be required to match the same resonant frequency.

A+!

On a reflex enckosure, the goal is keeping the high air velocity pathway and zones close to the port and rear of LF driver free of any dampening material that will hinder efficiency, reducing LF output. Ported boxes are hard to get right and you risk overly tubby sounding mid bass along with midrange leaking from the port with not enough or improper damping materials placed in the wrong areas. You just have to experiment with what sounds best to you and satisfies your taste.

Yes, so true.... vented boxes are hard to get optimized, especially if the woofer is expected to do midrange duty. A small 2-way ported speaker can be tricky to get stuffed just right.

Are there any good guides on how to measure and what to look for when adjusting the stuffing?

Is it just REW with a calibrated mic?

Do you just look for increased bass?

Is it just REW with a calibrated mic?

Do you just look for increased bass?

Last edited:

There are two reasons for fixing stuffing by glue or staples to the internal enclosure walls:Should there be any difference if you tack your stuffing wool to the walls, or you could randomly leave them in the space you need.

- If the stuffing can move it will be as effective at damping airborne energy, which is damped by the friction of air molecules being pushed through the fibres;

- If the stuffing is not attached to the cabinet walls it will not be as effective at damping cabinet resonances because if it is attached vibrations from the cabinet walls move the stuffing and friction between the fibres as they move damps the energy.

For your 1), assuming you use a soft insulation and not an open-cell foam, for example, you can only affix the part of the insulation that is immediately adjacent to an enclosure wall. The rest of the insulation is attached to... more insulation, so it's not like you can prevent the stuffing from moving, in practice.

Actually, now that I think about it, you can see how much of a factor that is by comparing Rockwool's rigid board to their softer stuff-in-place batts. I suspect it is not significant.

Actually, now that I think about it, you can see how much of a factor that is by comparing Rockwool's rigid board to their softer stuff-in-place batts. I suspect it is not significant.

If one part of the soft damping is fixed and air vibrations move another part, the friction between the fibres of the moving and non-moving sections will cause damping. This is an improvement over not fixing the damping at all. Of course with semi-rigid fibre panels they can be 'attached' by wedging them in place which achieves 1 & 2 above.

When i use fiber panels/sheets I use a regular office stapler to put a staple here and there where it makes sense to affix it.

If it's on the edges I tend to sneak the head of the stapler between the layers and basically just tack down the layer the most adjacent to the wall. It doesn't need to be super affixed; just stopped from literally moving out of place.

I cannot speak for loose fiber bunches as sealed speakers are not a thing I do very often.

If it's on the edges I tend to sneak the head of the stapler between the layers and basically just tack down the layer the most adjacent to the wall. It doesn't need to be super affixed; just stopped from literally moving out of place.

I cannot speak for loose fiber bunches as sealed speakers are not a thing I do very often.

OK, I understand. But how do you quantify how much the damping is moved by the sound waves, and what the effect of the overall motion is on the damping?If one part of the soft damping is fixed and air vibrations move another part, the friction between the fibres of the moving and non-moving sections will cause damping. This is an improvement over not fixing the damping at all. Of course with semi-rigid fibre panels they can be 'attached' by wedging them in place which achieves 1 & 2 above.

Do not use fibreglass batts for loudspeakers.

The particles cause cancer and they can be ejected from the port to zoom around the room getting to the whole family.

Use natural fibres.

The particles cause cancer and they can be ejected from the port to zoom around the room getting to the whole family.

Use natural fibres.

I don't have a simple answer so I'll digress somewhat. To some extent I use trial and error. If there is evidence of cavity resonance, I'll add more fill. For example a colleague brought in some B&W 801 S1 speakers because he wasn't happy with the low register. The bass had what I describe as a "bucket" sound.OK, I understand. But how do you quantify how much the damping is moved by the sound waves, and what the effect of the overall motion is on the damping?

To get an idea of what that is, hold a bucket near your head while you listen to music; you'll soon identify the sound signature of a cavity resonance of bucket dimensions. (BTW the same trick with glasses, coffee cups, drink bottles, etc, will give you an idea of the signature sounds of other resonances commonly found in loudspeaker systems. You can move the resonant object nearer or further from your ears to increase or decrease the resonant level compared to the sound level.)

On removing the 801 bass driver it was obvious that the cabinet was substantially packed with natural fibre absorbent damping (it is a sealed alignment). However the space immediately behind the bass driver was empty, forming an ~15-20 litre void in the densely packed absorbent. Loosening up the damping and distributing it more evenly without the void behind the driver removed the "bucket" effect from the bass. The redistribution of absorbent shouldn't adversely affect the 'Q' of the bass alignment because there was still the same amount of absorbent in the bass enclosure.

Listening to two different loudspeaker designs in succession is another good way to find the weaknesses in bothsystems, and identify the signatures of resonant modes that add unnaturalness in either system, and/or excessive damping that removes life from the sound.

I take every opportunity to listen to acoustic instruments with significant transient sounds such as piano, drums, etc without amplification. When these instruments are reproduced by loudspeakers it is often possible to identify sound that is not part of the character of the original instrument. This is because when the loudspeaker reproduces such an instrument the transient (attack) component of the sound excites all of the resonances in the loudspeaker which are not part of the orginal sound, thus unmasking them. This skill or discerning listening can be learned and continually improves. Warning: you will never listen to loudspeakers the same way again, but you will much more easily seperate the salt from the sugar even when listening to recordings, even ones you have never heard previously.

Glass fibers a listed as a possible carcinogen and should be handled with care. They probably should not be used in bass reflex enclosures.Do not use fibreglass batts for loudspeakers.

The particles cause cancer and they can be ejected from the port to zoom around the room getting to the whole family.

Use natural fibers.

Glass fibers do have one specific benefit; inside a sealed alignment they convert a component of the air compression/expansion into isothermal behaviour by absorbing and releasing the heat generated by compression and rarefaction of the air in the cabinet. This has the effect of making the internal volume of the cabinet appear bigger acoustically than it is mechanically, allowing for smaller enclosures for a given bass alignment.

Glass fibers are the best choice for this application because glass is thermally more conductive than other fibers such as polyester, acrylic or natural fibers, and allows faster heat interchange between the air and the fibers, creating a significantly greater proportion of isothermal behaviour than other fibers.

- Home

- Loudspeakers

- Multi-Way

- Does fiber type of stuffing need to be tacked to the walls?