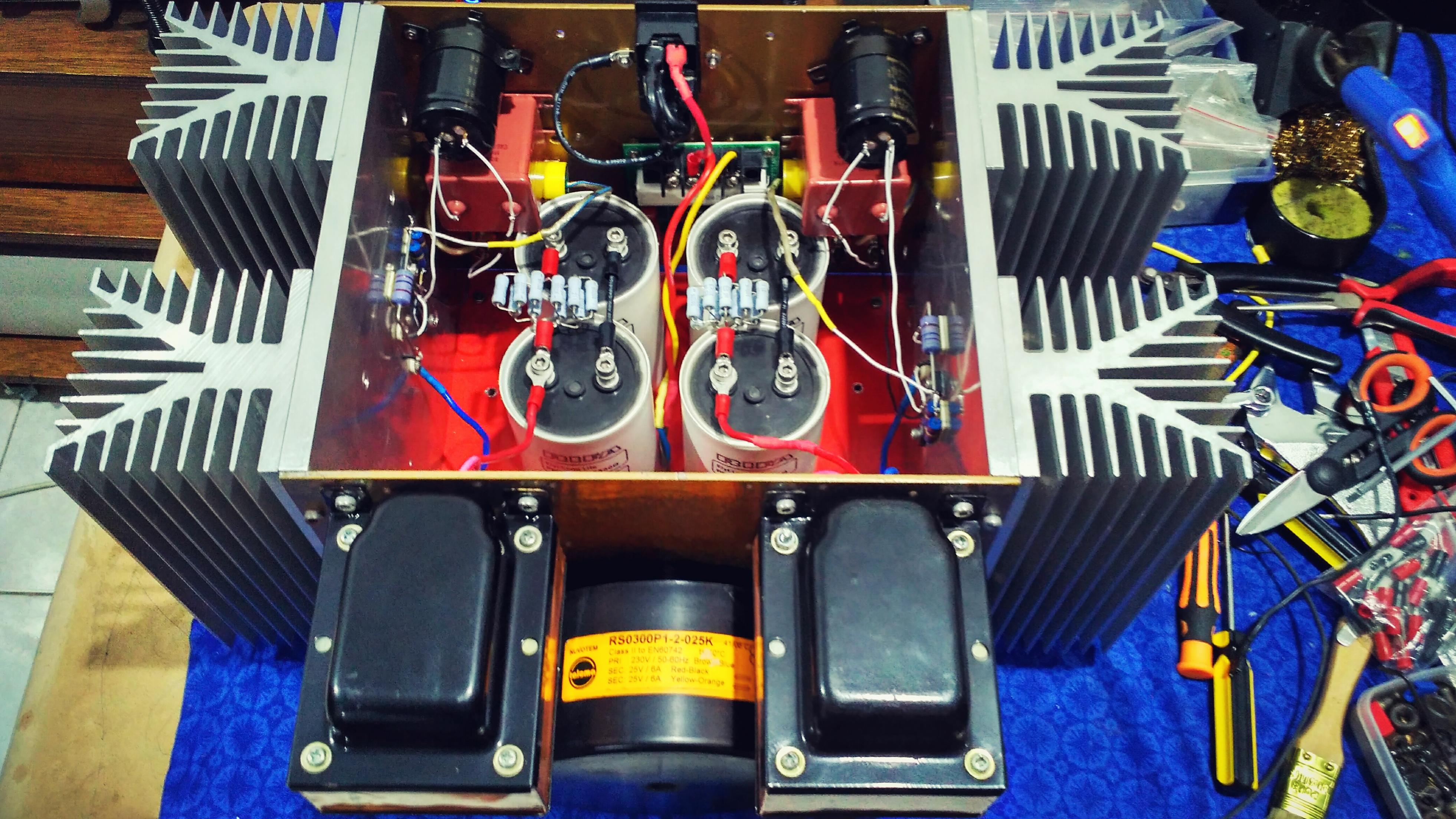

I have a DISPANTE 4U cabinet laying around, with very large heat sinks that I would like to use as an enclosure for a large MOFO Power AMP. It would pump out 20 watts at an idle current of 2.5 amps ( per channel )

The MOFO uses one power transistor / channel that requires a heat sink.

The Dispante 4U uses two equal sized heat sinks per side ( channel ).

Is there a reasonable way to thermally bridge the two heat sinks together, to form one large heat sink?

The MOFO uses one power transistor / channel that requires a heat sink.

The Dispante 4U uses two equal sized heat sinks per side ( channel ).

Is there a reasonable way to thermally bridge the two heat sinks together, to form one large heat sink?

Do you mean joining the two sinks together, or bridging them with some 3rd part connection. Because the sinks in the Disspante cabinets are some distance apart ?

A aluminium plate of reasonable thickness covering both heatsinks, overlapping maybe 100mm on each, so full heatsink height and minimum 200mm wide, would be my response. Use best insulator, and minimum heat paste, it seems easy but it's crucial for good transfer

Or go full width of both heatsinks with a 4-5 mm aluminium flat bar or angle, this will problaly distribute heat more even,

My Disspante is the 400mm deep option, not the standard 300 mm.

Mine has two 200mm sections that are held in place by brackets. They do touch, but not enough to transfer heat efficently.

So, I suppose I could leave them on the brackets and have them welded or take some flat aluminum stock, overlap the two heat sinks with some sort of thermal paste sandwiched between.

I was just wondering if someone else had a similar problem.

Mine has two 200mm sections that are held in place by brackets. They do touch, but not enough to transfer heat efficently.

So, I suppose I could leave them on the brackets and have them welded or take some flat aluminum stock, overlap the two heat sinks with some sort of thermal paste sandwiched between.

I was just wondering if someone else had a similar problem.

Last edited:

Buy a bigger heat sink, they are $3 a kilo here.

What you need is about $5 worth, not worth the effort of joining two heat sinks.

What you need is about $5 worth, not worth the effort of joining two heat sinks.

Banco and Jindal in India

Alcoa in the USA.

Search for heat sink sections.

Find someone who sells cut pieces, as the general lengths are 12 or 15 feet per section.

Or you could buy a full length if you need long term, cut with a chop saw.

Alcoa in the USA.

Search for heat sink sections.

Find someone who sells cut pieces, as the general lengths are 12 or 15 feet per section.

Or you could buy a full length if you need long term, cut with a chop saw.

The simplest would be ZenMod method of forced air using a computer fan running at a lower voltage (thus lower speed and nearly inaudible noise) on each heatsink and not bridging -- is that an option?

Otherwise, heavy stock to bridge the two with thermal goop, but even then the efficiencies drop at each interface. The over the top solution would be using copper heat pipes, but price, working with available shapes and forms, and attaching become major headaches.

Easiest is just using a massive large finned heatsink on each MoFo output device as it was originally designed. Those solid state relay style heatsinks can be found on-line with a few clicks. I salvaged a few of these heatsinks attached to SS relays I found locally.

Otherwise, heavy stock to bridge the two with thermal goop, but even then the efficiencies drop at each interface. The over the top solution would be using copper heat pipes, but price, working with available shapes and forms, and attaching become major headaches.

Easiest is just using a massive large finned heatsink on each MoFo output device as it was originally designed. Those solid state relay style heatsinks can be found on-line with a few clicks. I salvaged a few of these heatsinks attached to SS relays I found locally.

What I did was use 1/4” aluminum the full size of both heat sinks, lapped contacting surfaces on glass with 600 grit paper and applied a thin layer of thermal grease. When the amps ( F4 clones) reached equilibrium the heat sinks and 1/4” plate were precisely the same temperature showing me the air/ heatsink interface was far less efficient then the heatsink/heatsink interface. What really blows my mind my last amp build XRKs Alpha Nirvana I used cpu heat sinks with forced air - the temp on the heat pipe portion of the heatsink was higher than the device itself. I even placed kapton tape on both parts and they still measured the same offset.

Bill

Bill

Last edited:

Thx for the info.

I did apply some thermal grease to both heat sinks before butting them up against each other and securing them to the frame of the case, but I am not getting the results that I want.

So I will probably try your method with the 1/4 inch plate overlapping the two heat sinks.

I did apply some thermal grease to both heat sinks before butting them up against each other and securing them to the frame of the case, but I am not getting the results that I want.

So I will probably try your method with the 1/4 inch plate overlapping the two heat sinks.

A simple coupling without thermal paste and with a minimal overlapping surface is not effective in ensuring a good thermal coupling. The coupled surfaces must have a sufficient extension to ensure adequate heat exchange and be as smooth as possible and the thermal paste must be of good quality such as an Arctic MX4 or 5 especially if it is anodized surfaces that should be smoothed to remove anodizing from the contact surface because it is thermal insulator.

Last edited:

I-CAN´T-SEE-YOUR-PICTURESI have a DISPANTE 4U cabinet laying around, with very large heat sinks that I would like to use as an enclosure for a large MOFO Power AMP. It would pump out 20 watts at an idle current of 2.5 amps ( per channel )

The MOFO uses one power transistor / channel that requires a heat sink.

The Dispante 4U uses two equal sized heat sinks per side ( channel ).

Is there a reasonable way to thermally bridge the two heat sinks together, to form one large heat sink?

Oh, you ask but didn´t post any? 😕 🙄

HOW are we supposed to answer?

What does a "dispante" cabinet look like?

Never saw one, doubt many did.

Heat sinks are $3 a kilo here, how many hours did you spend in this, and what would your hourly rate be?

I'm using 10mm alum plate that cover both heatsink and put Sony 2SK82 between them, the plate is milled precisely on metal workshop

What is the power output expected?

When you do finish, keep a gap at the top and bottom between heat sink and shelf to allow air circulation.

This kind of heat sink may be happier with a fan.

And keep the heat sinks outside the enclosure, cover only the circuit, leave the transformers also outside.

When you do finish, keep a gap at the top and bottom between heat sink and shelf to allow air circulation.

This kind of heat sink may be happier with a fan.

And keep the heat sinks outside the enclosure, cover only the circuit, leave the transformers also outside.

Clarify the situation better if you want helpful answers. A photo of the dissipating 4U enclosure would be helpful. If, as I believe, it is a container with both sides made up of a single full-height heatsink, I don't think there are problems of insufficient surface. A photo would be better than many words.Thx for the info.

I did apply some thermal grease to both heat sinks before butting them up against each other and securing them to the frame of the case, but I am not getting the results that I want.

So I will probably try your method with the 1/4 inch plate overlapping the two heat sinks.

Dismantle case is the one sold in the diyaudio store for reference. I disagree removing anodizing from the surface to mate them. Anodizing is not a coating but a process that creates a 4 micron plus outer layer that is much harder and dense than the untreated aluminum and has been proven to improve heat conduction.

Bill

Bill

- Home

- Design & Build

- Construction Tips

- How do I thermally bridge two heat sinks?