It took me some time to get the courage to work on my Dual 701.I did some work on the electronic section replacing the capacitors and the discrete series regulator with a MC7815CT which also trips at 800mA so current protection is now included, just in case.... for those rare germanium transistors.

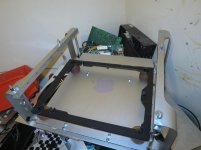

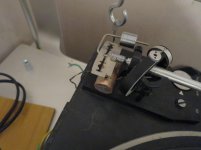

But what really drained me was to rework with copper and lead its tonearm counterweight cause i broke the original one out of curiosity just to see what dual resonant counterweight means...and it led me to the actual counterweight system which is develloped more on the horisontal being also heavier and closer to the pivot allowing both fixed and fine tuning weights to be damped.I actually cut by 2/3rd the internal brass rod attaching te counterweight to the toneram to make the tonearm itself as light as posible.More work on that later as i don't really like heavy tonearms and preffer to get the damping trough different methods .I also added my new semiautomatic 12 inch tonearm that has also end of record electric sensor and lift and conceived a leaf spring based system additional to its own spring damping system.Thus i removed the 701 original wooden enclosure and kept the internal platic support cut to a minimum and adding some more silicon rubber damping basically creating two completely separate damping systems that can also accomodate my other Dual 1219 turntable as 1219 and 701 need identical spring fixture .More work and photos later this year.

But what really drained me was to rework with copper and lead its tonearm counterweight cause i broke the original one out of curiosity just to see what dual resonant counterweight means...and it led me to the actual counterweight system which is develloped more on the horisontal being also heavier and closer to the pivot allowing both fixed and fine tuning weights to be damped.I actually cut by 2/3rd the internal brass rod attaching te counterweight to the toneram to make the tonearm itself as light as posible.More work on that later as i don't really like heavy tonearms and preffer to get the damping trough different methods .I also added my new semiautomatic 12 inch tonearm that has also end of record electric sensor and lift and conceived a leaf spring based system additional to its own spring damping system.Thus i removed the 701 original wooden enclosure and kept the internal platic support cut to a minimum and adding some more silicon rubber damping basically creating two completely separate damping systems that can also accomodate my other Dual 1219 turntable as 1219 and 701 need identical spring fixture .More work and photos later this year.

Attachments

-

IMG_5510.jpg835 KB · Views: 1,036

IMG_5510.jpg835 KB · Views: 1,036 -

IMG_5511.jpg819.1 KB · Views: 866

IMG_5511.jpg819.1 KB · Views: 866 -

IMG_5515.jpg866.8 KB · Views: 692

IMG_5515.jpg866.8 KB · Views: 692 -

IMG_5516.jpg865.4 KB · Views: 690

IMG_5516.jpg865.4 KB · Views: 690 -

IMG_5485.jpg976 KB · Views: 768

IMG_5485.jpg976 KB · Views: 768 -

IMG_5490.jpg787 KB · Views: 653

IMG_5490.jpg787 KB · Views: 653 -

IMG_5492.jpg900.4 KB · Views: 646

IMG_5492.jpg900.4 KB · Views: 646 -

IMG_5496.jpg900.9 KB · Views: 615

IMG_5496.jpg900.9 KB · Views: 615 -

IMG_5499.jpg957.3 KB · Views: 584

IMG_5499.jpg957.3 KB · Views: 584 -

IMG_5502.jpg891.7 KB · Views: 631

IMG_5502.jpg891.7 KB · Views: 631

@ ohsowise... it took four days just to attach the silicon rubber stands(actually silicon rubber wheels from a skateboard.) as they are glued with about 15 layers of rubber contact glue while cutting the plastic was indeed very stresful so it' not really for the faint hearted who wouldn't dare to "ruin such a german piece of engineering"...yet the original "dual resonant counterweight" is not exactly dual as the fine tuning counterweight is not flabby enough in my "not that german" view, nor it is distributed on the horizontal plane, but at least its mass is equaly distributed in all directions...And by the way internally the counterweight has a fine sheet of steel that's actually getting rusty and not that elastic in 50 years of use, but nobodys' checking it cause everybody knows it's only you who are allowed to express "internal" opinions on Duals guts. Next time i'll try better razors as gillette stainless steel isn't that steely anymore...I bet you know what are the best razors on the market, don't you? Next time when i'm going to replace the oil in the dd motor i'll ask explicitely for your permission cause i know you're the only expert ever in Duals! Fortunately someone dared to do that and measured the wow and flutter with the new oil without your permission already!

To completely redesign a turntable requires test equipment that can display tone arm resonances and that's just the start , there is no lack of engineering initiative but that has to be coupled with the engineering knowledge of massive changes in design which should be checked at each stage and tested with the appropriate equipment .

You make a point of Gillette razor blades , nothing would make me buy them anymore after condemning their largest majority of customers which lost them $$$$$$$$ in sales.

You make a point of Gillette razor blades , nothing would make me buy them anymore after condemning their largest majority of customers which lost them $$$$$$$$ in sales.

You didn't see the whole slaughter yet!Nice butcher job.

Did I mention that i used a 1219 with that same 701 plastic fixture? O yes, Dual, the german company used platic and cheap MDF, a lot of it in their best equipment not thinking that's cheap plastiky inside...

Although my 12inch tonearm has semiautomatic electrical lift , I forgot to tell that i removed half of 1219's mechanics meaning all the automation and one main feature that i want removed from the 701 too, but that won't happen soon with the 701 cause i need to figure out how to do it properly.Now the reason for removing the automation behind tonarm is due to a leverage that actually causes a tiny amount of friction when the tonearm is sliding over the record.May be small, but it's there all the time! Before Dual's guru would give advice on changing for less stifer tonearm wiring they'd better realise that the leverage inide the red-orange circles is causing 10 times more friction...

And...heresy, i put a 3.3uf/100v electrolitic reeplacing a 3.3uf/16v tantalum capacitor(actually meaured 4.4uf..) and some other capacitors here and there, even cutting the plastic enclosure over the EDS 1000 to accomodate them and the 78M15 regulator heatsink cause i don't care about precious "profesionnal modders " advice...and never will...

Attachments

Last edited:

Well...I've been a callibration and test engineer for various analytical chemistry and medical equipment more than a decade ago...If i could handle 5 decimals analytical weighing scales and million euros laser and x-ray machines, i hope i can "theoretically" handle a damn toneram today...To completely redesign a turntable requires test equipment that can display tone arm resonances and that's just the start , there is no lack of engineering initiative but that has to be coupled with the engineering knowledge of massive changes in design which should be checked at each stage and tested with the appropriate equipment .

You make a point of Gillette razor blades , nothing would make me buy them anymore after condemning their largest majority of customers which lost them $$$$$$$$ in sales.

I saw some recommending Feather razor blades here , but honestly those gilletes are 0.5 dollar for 5 razors...and i can replace them anytime.I didn't make a picture of the counterweight separately of the tonearm, but it's fairly easy to see in the pictures i provided that there's a sliding mechanism made out of fishing nylon wire and a brass pipe (taken from a ballpoint pen ) that also allows for lateral balancing with the fine tuning counterweight and it's especially useful for DUAL tonearms that have diplaced leverage acting with different force on the left and right gimbal bearings .The fixed counterweight is made by melting lead inside a copper collar pipe for electric use.Unfortunately i couldn't afford Platinum for that matter 🙂

Last edited:

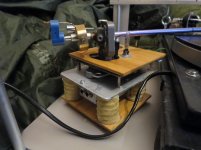

And this is made out of a a PowerMac case...some photos from older iterations also:

Attachments

- Home

- Source & Line

- Analogue Source

- Dual 701 and tonearm mods