Need help with the restauration of this vintage turntable (Yes I looked everywhere and can't find what I need)

Bought this TT sometime ago for spare/repair of the big auction site but it came without the belt pulley on the motor.

My question is for people with this turntable (don't know if the BD2 has the same one)

Can someone measure the pulley for me ?

Have access to machines (lathe/cnc lathe) to make one but need the dimension for the 2 speed groves.

Or if someone has one going spare...

Any one ?

Bought this TT sometime ago for spare/repair of the big auction site but it came without the belt pulley on the motor.

My question is for people with this turntable (don't know if the BD2 has the same one)

Can someone measure the pulley for me ?

Have access to machines (lathe/cnc lathe) to make one but need the dimension for the 2 speed groves.

Or if someone has one going spare...

Any one ?

The BD-1 and BD-2 use the same platter, motor, belt, and nylon pulley (friction fit on the shaft).

At some point the rubber motor suspension was improved on both. The original was just three rubber bands.

The suspension may have been damaged in shipping, but you can make a replacement from a 3" wide

flat rubber sheet.

Make sure the start knob still has the rubber kicker on it. This is essential for proper startup. If not,

you can substitute an eraser from a pencil of the right size. The original rubber kicker was threaded

into the knob.

At some point the rubber motor suspension was improved on both. The original was just three rubber bands.

The suspension may have been damaged in shipping, but you can make a replacement from a 3" wide

flat rubber sheet.

Make sure the start knob still has the rubber kicker on it. This is essential for proper startup. If not,

you can substitute an eraser from a pencil of the right size. The original rubber kicker was threaded

into the knob.

Last edited:

The BD-1 and BD-2 use the same platter, motor, belt, and nylon pulley. At some point the rubber motor suspension

was improved on both. The original was just three rubber bands. The suspension may have been damaged

in shipping, but you can make a replacement from a 3" wide flat rubber sheet.

Thanks but you didn't understood my question

My problem is the missing pulley the problem with the suspension rubbers is sorted.

To Dave

Do you know the name/nick for this member ?

Ric

I understand, but have no pulley. But you or others may have some of those problems as well.

A round cross section rubber belt of the right size is also difficult to source these days.

A round cross section rubber belt of the right size is also difficult to source these days.

Last edited:

Being in the UK, you have a much better chance of finding a Connoisseur spare part than most of us.

This guy seems to have some spare parts.

403 Forbidden

This guy seems to have some spare parts.

403 Forbidden

Last edited:

I understand, but have no pulley. But you or others may have some of those problems as well.

A round cross section rubber belt of the right size is also difficult to source these days.

The Suspension problem is a well known issue (no surprise in a 40 year old deck)

Funny enough the drive belt (and suspension upgrade) is easy enough to find online.

That guy (ebay shop) does have a few things but no drive pulley in stock and never had one (I asked a few weeks ago)

Last edited:

I've used a 3" flat rubber washer from the hardware store, and cut it to replace the original suspension.

Did this originally when they were new, and the suspension was damaged in shipping, but it works better

and much longer than the original.

Did this originally when they were new, and the suspension was damaged in shipping, but it works better

and much longer than the original.

If you have access to a machine shop, just take a guess and make one. If it's the wrong size (as measured by table RPM) simply reduce the size of the pully if it's going to fast or make a new larger one if it's going too slow.

And that what I probably will end up doing but I can only go there on Friday so will have to wait another 2 weeks (closed tomorrow Good Friday).

But there is always hope some one will come forward with a spare pulley.

But there is always hope some one will come forward with a spare pulley.

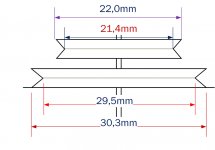

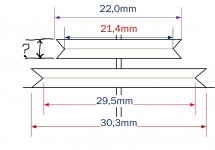

Here is sketch With thickness dimensions

But, my recommendation is to to recalculate pulley for flat belt as it is much easier to find replacement flat belt than original rounded one. That would be easily done with knowing dimension of platter and knowing the rotating speed of the motor which is exactly 375 RPM for 50Hz AC.

But, my recommendation is to to recalculate pulley for flat belt as it is much easier to find replacement flat belt than original rounded one. That would be easily done with knowing dimension of platter and knowing the rotating speed of the motor which is exactly 375 RPM for 50Hz AC.

Attachments

Round belts can be find at ball bearing sellers stores, the o-ring gaskets are suitable for that purpose.

I have a BD 1 tucked away somewhere. the original drive belt is much softer and more compliant than an O ring designed for sealing a joint.

- Home

- Source & Line

- Analogue Source

- Help with Sugden Connoisseur BD1