For those who didn't see them yet, the new Mark Audio CHN110 drivers...

specs: https://www.markaudio.com/wp-content/uploads/2019/12/CHN110-with-plans.pdf

specs: https://www.markaudio.com/wp-content/uploads/2019/12/CHN110-with-plans.pdf

Attachments

For those who didn't see them yet, the new Mark Audio CHN110 drivers...

specs: https://www.markaudio.com/wp-content/uploads/2019/12/CHN110-with-plans.pdf

Excellent, thanks

1,001 299,721

---------

Fostex

Attachments

Last edited:

Excellent, thanks

1,001 299,721

---------

Fostex

I sent you a private message would welcome a response, you answer here or answer my private message, thanks.

Some fullrange drivers with

Some fullrange drivers with aluminium foil. I like to cover my fullrange drivers with aluminium foil, one side or both sides.

Fostex FE 208 sigma center dust cap covered with aluminium foil and back side (not here on foto).

Some small bluetooth loudspeaker with aluminium covered diaphragm.

Sica 12D fullrange driver with copper foil and aluminium foil.

Some cheap fullrange driver from germany - pretty linear from 100 Hertz to 10 Khz without whizzer cone. Works nice.

Why aluminium on fullrange drivers?

D.A. Barlow: The Development of a Sandwich-Construction Loudspeaker System. Page 159-171. From the AES anthology of articles on loudspeakers, article written 1970.

Citation begin (page 160):

"As paper cones are thin, these resonances are bending modes. The stiffness of a material in bending, for any given geometry and edge condition, is proportional to Young`s modulus and the cube of the thickness, ignoring variations in Poisson`s ratio. ... On this basis, paper is much stiffer than metals (except beryllium) in spite of its much lower modulus, and lower density materials such as expanded plastics are even stiffer, as may be seen in Table. A method of obtaining still greater stiffness is sandwich construction. ... In bending, the maximum stress and strain occur at the outer fibers, the material at the neutral axis being unstressed. Better use of material can thus be made by concentrating it at the outer fibers. A familiar example is the tube. In the case of large areas, the same effect is obtained by using a thin high-modulus material for the outer surfaces, and a light-weight material or form of construction for the core. ... This sandwich will of course be much stiffer than the same total weight of either material used separately. The skin material should have the maximum ratio of modulus/density. Beryllium, the best material, is impractical due to difficulty of rolling and possible toxicity, so aluminium is the obvious choice. The core should be as stiff as possible in the thickness direction and have minimum density. Honeycomb aluminium or impregnated paper are frequently used in aircraft construction and could be used for flat diaphragms."

Citation end.

Some fullrange drivers with aluminium foil. I like to cover my fullrange drivers with aluminium foil, one side or both sides.

Fostex FE 208 sigma center dust cap covered with aluminium foil and back side (not here on foto).

Some small bluetooth loudspeaker with aluminium covered diaphragm.

Sica 12D fullrange driver with copper foil and aluminium foil.

Some cheap fullrange driver from germany - pretty linear from 100 Hertz to 10 Khz without whizzer cone. Works nice.

Why aluminium on fullrange drivers?

D.A. Barlow: The Development of a Sandwich-Construction Loudspeaker System. Page 159-171. From the AES anthology of articles on loudspeakers, article written 1970.

Citation begin (page 160):

"As paper cones are thin, these resonances are bending modes. The stiffness of a material in bending, for any given geometry and edge condition, is proportional to Young`s modulus and the cube of the thickness, ignoring variations in Poisson`s ratio. ... On this basis, paper is much stiffer than metals (except beryllium) in spite of its much lower modulus, and lower density materials such as expanded plastics are even stiffer, as may be seen in Table. A method of obtaining still greater stiffness is sandwich construction. ... In bending, the maximum stress and strain occur at the outer fibers, the material at the neutral axis being unstressed. Better use of material can thus be made by concentrating it at the outer fibers. A familiar example is the tube. In the case of large areas, the same effect is obtained by using a thin high-modulus material for the outer surfaces, and a light-weight material or form of construction for the core. ... This sandwich will of course be much stiffer than the same total weight of either material used separately. The skin material should have the maximum ratio of modulus/density. Beryllium, the best material, is impractical due to difficulty of rolling and possible toxicity, so aluminium is the obvious choice. The core should be as stiff as possible in the thickness direction and have minimum density. Honeycomb aluminium or impregnated paper are frequently used in aircraft construction and could be used for flat diaphragms."

Citation end.

Attachments

Pioneer

Made. by Panaosonic. I had a set of those thru are. Nice.

dave

Made. by Panaosonic. I had a set of those thru are. Nice.

dave

Imma Really need glasses .....

--------------------------------------------------------------

For those 12 inch, and 15 inch fullrange,

This might be a start >

Attachments

I love the last bullet.

“Cuts economically from standard 4’ x 8’ plywood panels”

Notice they didn’t say how many. 😀

“Cuts economically from standard 4’ x 8’ plywood panels”

Notice they didn’t say how many. 😀

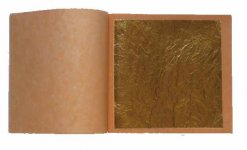

This thin quality aluminium foil you get from shops who sell thin gold for gilding. It's leaf aluminium. You use the same glue they use. In German it's "Anlegemilch dick".That's interesting, how do you cover the speaker with foil?

Oon

Shops like these

https://noris-blattgold.de/

But you can use also simple alu foil from the household and simple universal glue like pattex

My first project was a Fostex F208∑ with alu foil on all sides in a Jericho Horn from Klang und Ton magazine.

I do this since the year 2000.

I described the method on a website from year 2000 to 2010. But I never saw anyone trying to do the same. Only one from San Francisco who was on the fullrange forum melhuish. org.

I visited him in 2004 when I made a trip to California.

I do this since the year 2000.

I described the method on a website from year 2000 to 2010. But I never saw anyone trying to do the same. Only one from San Francisco who was on the fullrange forum melhuish. org.

I visited him in 2004 when I made a trip to California.

Attachments

Last edited by a moderator:

He aluminized a pair of fullrangers hung to the corners close to the ceiling.

And he liked doing it to dust caps of small fullrange drivers

And he liked doing it to dust caps of small fullrange drivers

- Home

- Loudspeakers

- Full Range

- full range pics-