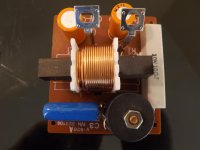

This is a crossover from a BIC America V-820 2-way speaker made in 1994. I want to know: 1) are both orange-yellow caps bipolar/not polarized? 2) are they the type they call electrolytic? 3)What does the blue one do, what type is it, and what does "4.5K 100V MER CH" mean? Accepting any and all advice on cap upgrades. Thanks!

Attachments

1) and 2). Both orange caps are bipolar electrolytic - quite common in crossovers.

3). The blue one is MKT type capacitor - better than bipolar electrolytic, but more expensive. It is part of the tweeter high-pass filter here, together with the smaller inductor.

4.5K = 4.500 nano Farads = 4.5 micro Farads.

MER = Metallized Polyester Film (MKT)

100V = maximum voltage

3). The blue one is MKT type capacitor - better than bipolar electrolytic, but more expensive. It is part of the tweeter high-pass filter here, together with the smaller inductor.

4.5K = 4.500 nano Farads = 4.5 micro Farads.

MER = Metallized Polyester Film (MKT)

100V = maximum voltage

Last edited:

Unless you have measurement facilities, it is best to replace capacitors like for like i.e. electrolytic for electrolytic and film for film. Otherwise you could end up making the speaker sound worse and not better.Accepting any and all advice on cap upgrades. Thanks!

You could look for high quality bipolar electrolytics and MKP (polypropylene) film capacitors if you are intent on upgrading.

Having said that, 26 years is not particularly long in the life of a loudspeaker crossover, especially when yours appears to be of reasonable quality to begin with.

Since I'm always interested in speaker systems that are new to me, I searched for your V820 speakers!

I might as well share my finding with other interested parties: B.I.C. Venturi V820 Speaker System Review price specs - Hi-Fi Classic

I might as well share my finding with other interested parties: B.I.C. Venturi V820 Speaker System Review price specs - Hi-Fi Classic

Who on earth came up with that marking scheme? Why not just say 4µ5 ?4.5K = 4.500 nano Farads = 4.5 micro Farads.

I despair of capacitor manufacturers and their perverse aversion to nanofarads 🙂

I too found this a few years ago. Cool piece of nostalgia.Since I'm always interested in speaker systems that are new to me, I searched for your V820 speakers!

I might as well share my finding with other interested parties: B.I.C. Venturi V820 Speaker System Review price specs - Hi-Fi Classic

Thank you!1) and 2). Both orange caps are bipolar electrolytic - quite common in crossovers.

3). The blue one is MKT type capacitor - better than bipolar electrolytic, but more expensive. It is part of the tweeter high-pass filter here, together with the smaller inductor.

4.5K = 4.500 nano Farads = 4.5 micro Farads.

MER = Metallized Polyester Film (MKT)

100V = maximum voltage

Plastic film capacitors do not tend to wear out except in AC mains surge prevention service. X & Y capacitors do wear out due to thousands of volt spikes on the AC line. X & Y capacitors are not used in speakers.

Polyester is reputed to produce more distortion than polyprophylene dielectric.

Electrolytic capacitors tend to dry out due to cracks in the rubber seal. Different sealants have different aging rates. You are not allowed to know what sealant was used, but datasheets do sometimes provide a service life rating @ a certain temperature. 1000 hours service life is garbage, 10000 hours up are state of the art. Farnell & digikey allow you to see the service life in the selector table. mouser makes you download the datasheet and read it. Alliedelec only carries 1000 hour service life. Parts-express won't tell you anything about brand, manufacturer part number, or service life of electrolytic caps. Service life is typically not published for bipolar electrolytic caps.

Polyester is reputed to produce more distortion than polyprophylene dielectric.

Electrolytic capacitors tend to dry out due to cracks in the rubber seal. Different sealants have different aging rates. You are not allowed to know what sealant was used, but datasheets do sometimes provide a service life rating @ a certain temperature. 1000 hours service life is garbage, 10000 hours up are state of the art. Farnell & digikey allow you to see the service life in the selector table. mouser makes you download the datasheet and read it. Alliedelec only carries 1000 hour service life. Parts-express won't tell you anything about brand, manufacturer part number, or service life of electrolytic caps. Service life is typically not published for bipolar electrolytic caps.

Last edited:

Note, David, that you may find high quality axial bipolar electrolytics easier to source than high quality radial ones (unless someone here can point to a supplier of the latter).

Your electrolytics are radial capacitors which have two leads that stick out from the bottom of the capacitor. Axial capacitors have one lead that sticks out from either end.

Your electrolytics are radial capacitors which have two leads that stick out from the bottom of the capacitor. Axial capacitors have one lead that sticks out from either end.

Last edited:

Thank you everyone. ERSE has 3% DF axials; best electrolytics I have found yet. Are they in USA? Shipping will be 20 times the parts cost!

Nichicon makes some nice bipolar audio grade capacitors. Digikey and Mouser both carry them. As Galu pointed out your caps are radial, not axial.

use parts connexion , for the tweeter use quality poly caps , for woofer Nichicon makes electrolytes that are good and cheap in 22uf and higher values .... replace cheap sand cast resistor with Mundorf or Mills .... also wiring should be replaced for quality copper

- Home

- Design & Build

- Parts

- Crossover Identification