It has already happened DECADES ago, all over the place, with tubes retaining a microscopic part of the Market, in tiny very very specialized niches.So we can say that it is because nobody is developing tubes technologies anymore? so in the near future solid state will replace tubes completely, finally?

That WE love them, and keep using them, does not impress factory shareholders very much, they prefer to invest their money in more dynamic areas of Economy.

It is also a matter of supply and demand. There are probably 25 or less different types of new production vacuum tubes being manufactured in large quantities today. These are the common types being made for guitar and HiFi amplifiers. If someone wanted to design a vacuum tube product for mass marketing they would need to choose from only those 25 tube types (and realistically only 12 types) to ensure a long running supply of replacement tubes. Those start at the 12AX7 sized tubes and get larger.

If someone was building DIY equipment for themselves, or limited small volume production, they could choose from thousands of tube types that were made long ago, some of which are quite small. I have used some tiny tubes originally intended for hearing aids and military technology like those shown in post#3 for a vacuum tube preamp that fits inside an electric guitar body, and for some music synthesizer modules.

As I recently found out the NOS (New Old Stock) vacuum tube supply situation changes continuously. One of my suppliers sold out to someone who wants $5 each for a tube that I was getting for $.35, and the other passed away leaving nearly 5 million tubes unavailable at any cost. These risks have put my company in danger of extinction, since I have chosen to rely on tubes that are not being made today.

If someone was building DIY equipment for themselves, or limited small volume production, they could choose from thousands of tube types that were made long ago, some of which are quite small. I have used some tiny tubes originally intended for hearing aids and military technology like those shown in post#3 for a vacuum tube preamp that fits inside an electric guitar body, and for some music synthesizer modules.

As I recently found out the NOS (New Old Stock) vacuum tube supply situation changes continuously. One of my suppliers sold out to someone who wants $5 each for a tube that I was getting for $.35, and the other passed away leaving nearly 5 million tubes unavailable at any cost. These risks have put my company in danger of extinction, since I have chosen to rely on tubes that are not being made today.

Whatever happened to the cold-cathode electron emitter? I'd thought I had read something about this being a nano-tech, where arrays of electron-microscope sized spikes were created that could send electron off the tips - cold.

That might go some way toward miniaturization. Never heard about it again.

Device physicists have been looking into vacuum microelectronics with field emission cathodes for decades, fascinated by the high speeds/small transit times you could theoretically obtain when you combine the high electron mobility in vacuum with microscopic sizes, but it has produced only very few usable devices so far. One problem is the lack of P-type devices, the other all sorts of reliability issues with the cathodes. Apparently some travelling-wave tubes are now manufactured with a cold cathode based on field emission and there were also some exotic displays made based on this technology.

That Nutube is interesting, but how many do you think you'll need to put in || to get 1.75W to go play in the SE 45 arena?

Douglas

Douglas

Now adays there are mechanical parts inside microchips (gyros, accelerometers....)

That is incorrect. They are NOT mechanical parts, they are solid state. Google it, there is plenty info available.

Member

Joined 2009

Paid Member

of course they're mechanical, they rely on moving parts. They’re called MEMS devices, check out what the 2nd ‘M’ stands for!

Member

Joined 2009

Paid Member

when it boils down to system size, tubes are not all bad - just look at the size of heatsinks on a solid state amplifier.

of course they're mechanical, they rely on moving parts. They’re called MEMS devices, check out what the 2nd ‘M’ stands for!

Show me a MEMS device that is built into a microchip.

That is incorrect. They are NOT mechanical parts, they are solid state. Google it, there is plenty info available.

You are incorrect. MEMS are mecanical by definition:

"MEMS stands for micro electro mechanical system and applies to any sensor manufactured using microelectronic fabrication techniques. These techniques create mechanical sensing structures of microscopic size, typically on silicon."

Many Gyros and accelerometers are MEMS.

There are also optomechanical based chips.

refs:

Introduction to MEMS Accelerometers

Optomechanical Accelerometers | NIST

when it boils down to system size, tubes are not all bad - just look at the size of heatsinks on a solid state amplifier.

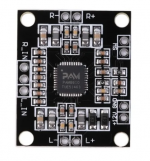

This thing is 1x1 inch and can deliver plenty 5W without a heatsink:

it's a shame tha it sounds like crap on clipping. Imagine somethig similar but with tubes. But it sounds impossible.

You are incorrect. MEMS are mecanical by definition:

Read my post #29

Then there are these small tubes that use actual heatsinks:

https://frank.pocnet.net/sheets/140/8/8560A.pdf

Unfortunately they often used Beryllium Oxide thermal blocks or compound which

could be very dangerous under the right conditions.

Note the anode dissipation.

https://frank.pocnet.net/sheets/140/8/8560A.pdf

Unfortunately they often used Beryllium Oxide thermal blocks or compound which

could be very dangerous under the right conditions.

Note the anode dissipation.

Member

Joined 2009

Paid Member

Show me a MEMS device that is built into a microchip.

Not sure if you are just being pedantic about dictionary definitions or are asking about something more meaningful, anyway, check out the meaning of the first ‘M’ in MEMS.

Many MEMS devices are designed to be produced from silicon wafers, enjoying the same ability to scale production as non mechanical chips. But the processes are not the same. There are many different silicon wafer processes, optimized for different tasks e.g. you will find memory chips use a different process than image sensors. For the most part it makes more sense to package MEMS chips separately from memory chips and separately from image sensors etc. There are advanced 3d chip-stacking techniques that allow chips made from different silicon processes to be combined into a single package where it makes sense to do so.

If you have a genuine interest in MEMS please PM me, my employer owns two MEMS foundries.

Last edited:

Tubes work with high voltage. Safety dictates a minimum distance between their pins. Capacitors at this voltage are not small either. Neither are the output transformers.

Tube radios/TV sets were designed so that the users (with their clumsy hands) could fix them by replacing the burnt-out tubes. When I was child, one could buy radio and TV tubes at every electric shop. Obviously a tiny part would have been more difficult to replace. Radio and TV sets were pieces of furniture in nice wooden case, where size was not an issue, and since the loudspeaker was also built in, it should be big.

Finally: octal, noval, magnoval etc. sockets became de-facto standard, and there was no motivation to replace them later. Samller sizes would require tighter tolerances, wich again would not be economical.

Tube radios/TV sets were designed so that the users (with their clumsy hands) could fix them by replacing the burnt-out tubes. When I was child, one could buy radio and TV tubes at every electric shop. Obviously a tiny part would have been more difficult to replace. Radio and TV sets were pieces of furniture in nice wooden case, where size was not an issue, and since the loudspeaker was also built in, it should be big.

Finally: octal, noval, magnoval etc. sockets became de-facto standard, and there was no motivation to replace them later. Samller sizes would require tighter tolerances, wich again would not be economical.

There is nothing stopping someone from making high power tubes on a TO-264 or similar power transistor package now. No heaters needed. Just three pins for a triode.

High current density cathodes that don't require a heater are easy to make since year 2000:

https://www.diyaudio.com/forums/tubes-valves/176600-nutty-idea-dont-didnt-warn-2.html#post2354828

https://www.diyaudio.com/forums/tubes-valves/1679-interesting-thought.html#post12238

https://www.diyaudio.com/forums/tubes-valves/228301-diamond-cathode-tubes.html#post3337529

The single layer cathodes can be made using just an electroplating bath in a dish at home.

The later multi layer cathodes actually reached room temp functionality.

Micro perforated grids are easy to make with a laser. The pixel mesh in color TV tubes were made that way.

Can probably just order it in sheets from some source still and cut pieces to size..

The plate would just be the copper mounting tab with a getter material coating.

Its easier to make one of these than to make old tubes.

The package would be a ceramic and planar electrodes sandwich to hold a good vacuum and insulate the electrode layers.

Nothing needed except a vacuum pump and induction heater to seal (silver braze) the metal film coated ceramic layers together. Standard Ceramic Hybrid packages available like this long ago. (came with pre-"tinned" ceramic pieces, ready to be heated to "solder" layers together)

High current density cathodes that don't require a heater are easy to make since year 2000:

https://www.diyaudio.com/forums/tubes-valves/176600-nutty-idea-dont-didnt-warn-2.html#post2354828

https://www.diyaudio.com/forums/tubes-valves/1679-interesting-thought.html#post12238

https://www.diyaudio.com/forums/tubes-valves/228301-diamond-cathode-tubes.html#post3337529

The single layer cathodes can be made using just an electroplating bath in a dish at home.

The later multi layer cathodes actually reached room temp functionality.

Micro perforated grids are easy to make with a laser. The pixel mesh in color TV tubes were made that way.

Can probably just order it in sheets from some source still and cut pieces to size..

The plate would just be the copper mounting tab with a getter material coating.

Its easier to make one of these than to make old tubes.

The package would be a ceramic and planar electrodes sandwich to hold a good vacuum and insulate the electrode layers.

Nothing needed except a vacuum pump and induction heater to seal (silver braze) the metal film coated ceramic layers together. Standard Ceramic Hybrid packages available like this long ago. (came with pre-"tinned" ceramic pieces, ready to be heated to "solder" layers together)

Last edited:

Very interesting information from @smoking-amp

It appears that the only valid reason in 2021 to not make smaller better tubes is the market.

It appears that the only valid reason in 2021 to not make smaller better tubes is the market.

It appears that the only valid reason in 2021 to not make smaller better tubes is the market.

Yes. And the only reason in 2021 not to make smaller better steam locomotives is the market. 🙄

- Home

- Amplifiers

- Tubes / Valves

- Why are the tubes so huge?