I just ordered new HF diaphrams for my coaxial BMS 4594ND's.

I've reconed lots of speakers, but I've never replaced a "soldered in" diaphram in my life, which I assume these are.

Since this is a coaxial design, I'm especially concerned.

Is there any trick to this, or a common mistake to watch out for?

Do I just solder these in place, or leave a little slack in the leads, or.... ?

Anyone know of a video that shows this being done?

- thanks.

I've reconed lots of speakers, but I've never replaced a "soldered in" diaphram in my life, which I assume these are.

Since this is a coaxial design, I'm especially concerned.

Is there any trick to this, or a common mistake to watch out for?

Do I just solder these in place, or leave a little slack in the leads, or.... ?

Anyone know of a video that shows this being done?

- thanks.

I'd be very surprised if it's soldered in at all. Usually, the push-spring terminals are attached to the plastic/metal frame that holds the diaphragm. Unscrew the cover, old diaphragm out, check the magnetic gap for any bits, new diaphragm in, cover back on and keep on rocking.

How did you break the old HF diaphragms?

Chris

How did you break the old HF diaphragms?

Chris

How on earth did you kill the driver?

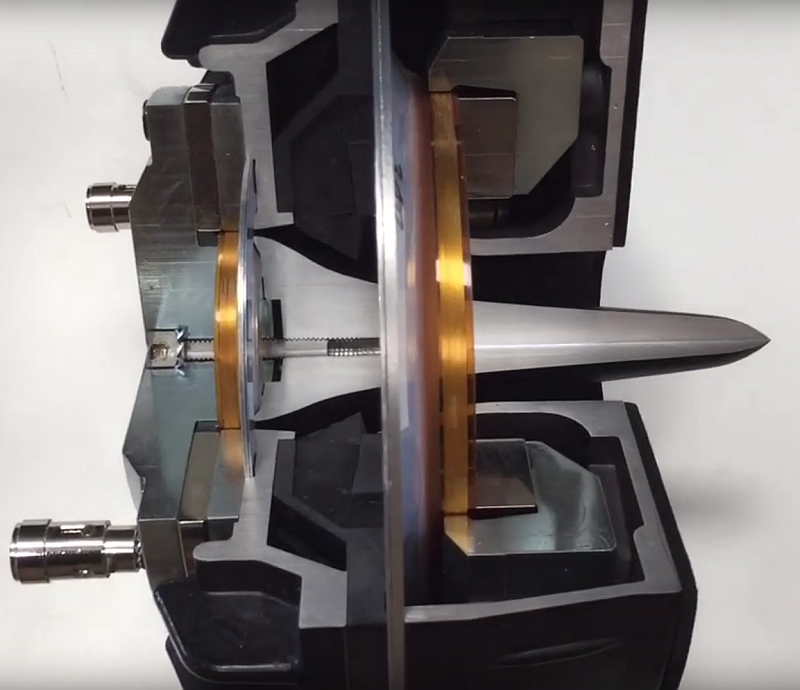

You have to remove some more effort because the mid diaphragm is at a different location than the high diaphragm. It's not complicated and you don't need to be skilled for it though as both diaphragms are forced-/self-centering (like in all modern compression drivers).

Here you can see what to expect:

You have to remove some more effort because the mid diaphragm is at a different location than the high diaphragm. It's not complicated and you don't need to be skilled for it though as both diaphragms are forced-/self-centering (like in all modern compression drivers).

Here you can see what to expect:

How did you break the old HF diaphragms?

Chris

I was running them without the EAW processor (I have it now) and my own "by ear" eq.

The amp was a bit too powerful, and I can get a little carried away as a DJ! 😱

---------------------------

BTW -

Most of you guys probably know this, but just in case:

My HF diaphrms are damaged, but not completely blown, which I always thought was not possible. I've read before that a diaphram is either blown or fine, but Steve Davis at EAW says it's very common for these to start sounding off, yet still pass audio.

He told me to run a sinewave sweep, at medium volume, and listen for changes. A bad midrange should sound like a "double note" (tartini tones, etc) from about 250 Hz - 1.6K, and the HF will just be obvious.

Sure enough, The tone completely fell apart at just under 4K. (the HF x-over is around 6.5k, so that makes sense)

The speakers still pass HF, it just sounds nasty.

Last edited:

I was running them without the EAW processor (I have it now) and my own "by ear" eq.

The amp was a bit too powerful, and I can get a little carried away as a DJ! 😱

Well, there are a lot of thing you can to by ear. Creating a setup might be sound-wise but is not one of them for appropriate PA levels. 🙄

My HF diaphrms are damaged, but not completely blown, which I always thought was not possible. I've read before that a diaphram is either blown or fine, but Steve Davis at EAW says it's very common for these to start sounding off, yet still pass audio.

No, that's a common misconception. Overload can kill a coil completely or create a few windings to separate from the coil former or may lead to the VC/former separate from the diaphragm. A thermal overload can also short some/all of the coil windings which leads to a way-off impedance, which makes a passive crossover shift the filter parameters since it's purely impedance dependend.

He told me to run a sinewave sweep, at medium volume, and listen for changes. A bad midrange should sound like a "double note" (tartini tones, etc) from about 250 Hz - 1.6K, and the HF will just be obvious.

Sure enough, The tone completely fell apart at just under 4K. (the HF x-over is around 6.5k, so that makes sense)

The speakers still pass HF, it just sounds nasty.

Since the short of coil windings can change that a lot, on a passive you can't take that for a fact. It's still a strong indicator though and in this case very likely correct. If you want to save your driver from too low frequencies because of a wrong DSP setup, put a foil capacitor in the circuit, for the mid it's ~47µF, for the HF it's 10µF.

Thanks for that technical explanation, ICG.

Much appreciated!

I'm curious: Do you have a better method for testing the condition of driver diaphrams?

-----------------

And as I mentioned, I now have a UX3600 processor, with the greybox limit settings set to my Lab Gruppen's max voltage and gain settings. So theoretically I should be good from now on.

Much appreciated!

I'm curious: Do you have a better method for testing the condition of driver diaphrams?

-----------------

And as I mentioned, I now have a UX3600 processor, with the greybox limit settings set to my Lab Gruppen's max voltage and gain settings. So theoretically I should be good from now on.

UPDATE: (help!)

Well, my new HF diapragms are here, and I have the HF component removed from the speaker... and it is a solder-in type.

Additionally, the thin aluminum ring around the circumference of the diapragm is fairly "stuck" on. (There's a lot of white powdery residue all over the driver's body, which appears to be something that spread out and dried. That's probably what's holding the diaphragm ring so tight.)

I can't find ANYTHING online about how to do this., so:

------------------

1: Do I just pry it off, or am I supposed to heat it up first?

# 2: Could that white powdery stuff be evaporated ferrofluid? (or some other heat wicking compound? No one from EAW mentioned that these use ferrofluid.

3: How do I know which lead is positive? they're actually not marked!

Is it the one next tot the "8 ohm" mark?

4: Again, should the soldered leads have some slack, or nice & tight?

5: What's the best way to clean the coil gap, before installing the new diaphragm?

One article recommends brake cleaner, but I don't have any.

Alcohol, thin cloth, and a needle?

(& Anything else to worry about?)

- thanks.

Well, my new HF diapragms are here, and I have the HF component removed from the speaker... and it is a solder-in type.

Additionally, the thin aluminum ring around the circumference of the diapragm is fairly "stuck" on. (There's a lot of white powdery residue all over the driver's body, which appears to be something that spread out and dried. That's probably what's holding the diaphragm ring so tight.)

I can't find ANYTHING online about how to do this., so:

------------------

1: Do I just pry it off, or am I supposed to heat it up first?

# 2: Could that white powdery stuff be evaporated ferrofluid? (or some other heat wicking compound? No one from EAW mentioned that these use ferrofluid.

3: How do I know which lead is positive? they're actually not marked!

Is it the one next tot the "8 ohm" mark?

4: Again, should the soldered leads have some slack, or nice & tight?

5: What's the best way to clean the coil gap, before installing the new diaphragm?

One article recommends brake cleaner, but I don't have any.

Alcohol, thin cloth, and a needle?

(& Anything else to worry about?)

- thanks.

Last edited:

1: Do I just pry it off, or am I supposed to heat it up first?

Pry it off carefully. Heating it up makes it expand (and it will heat up much faster than the driver), so it will be much harder to get out. You could use cold spray.

# 2: Could that white powdery stuff be evaporated ferrofluid? (or some other heat wicking compound? No one from EAW mentioned that these use ferrofluid.

The driver got no ferrofluid in it, FF becomes a tar like mass. The white powdery stuff is oxidation from the aluminium and it's a sign water or rather salt water or other fluids with salts in it likely entered the driver. The aluminium oxidyzes on the surface and - usually - protects it from further corrosion. Salts can destroy that layer and the aluminium becomes brittle and expands (that's why you can't remove it easily). Did you clean it with an (aggressive?) cleaning detergent? It is most likely it entered the driver from the front. You should also check the mid diaphragm.

3: How do I know which lead is positive? they're actually not marked!

Is it the one next tot the "8 ohm" mark?

I don't know that, usually on the most drivers you can only place the diaphragm one way and the + got often some kind of marking, a point or similar. It's not a big issue though, you can always switch the cables and the markings on the driver later, so that's not a big issue anyway. You can check the correct polarity with a simple mic and a measurement program. There are even apps for phones which can check it.

4: Again, should the soldered leads have some slack, or nice & tight?

The leads are glued to the aluminium spacer, a tight lead should not make any difference. I'd leave them a bit loose but they may not have that much slack they could get in the way of the aluminium spacer/membrane mounting ring. That ring has to sit plane, otherwise the distortion will be increased.

5: What's the best way to clean the coil gap, before installing the new diaphragm?

Isopropyl Acohol, ~70+%, the exact percentage is not very important but it has to be clean. A high alcohol percentage lets it dry much faster. The cleaning properties are better if some water is in it, so using 99/100% alcohol does not improve it. Use a cotton or micro fiber cloth, the former being usually better since it doesn't leave micro fibers behind (which aren't critical though). Let it vent after cleaning so it can evaporate.

One article recommends brake cleaner, but I don't have any.

Alcohol, thin cloth, and a needle?

Brake cleaner is really bad since it can dissolve a lot of glues and is aggressive towards plastic since it washes out the softener or even dissolves them (that includes the diaphragm and the insulation varnish of the VC). That is especally cricically since the 2nd diaphragm is still in the driver and brake cleaner 'creeps' extremely. It's gone fast but it can only be used safely if you can remove every plastic or glued part first. It's the easiest to get ferrofluid out of old drivers though.

Do not use any fluids directly on the driver, just make the cloth damp (not wet). Fibers and dust can be blown out (don't blow with the mouth).

(& Anything else to worry about?)

Yes, please take pictures of the old diaphragm and the inside of the driver, post them here to see if I'm actually right, I cannot think about something else than corrosion at the moment but I still might be wrong. If it actually is some kind of salt, you need to find the source. Also, all salt residue has to be removed or it will start again. Do you live close to the sea (within 50km)?

Wow, ICG you are da' MAN !

thanks.

I'll check the mids tonight & clean what I can without actually replacing them.

- Maybe I should desolder / remove them & clean those gaps as well?

I started a separate thread just about the white powder, as this was a serious emergency. A pic of the HF assembly is there, but here it is again:

Dropbox - BMS HF DRIVER - RESIDUE.jpg - Simplify your life

I'll take pics of the rest in a few minutes.

============================

As for salt water, I have no idea. I bought these second hand. They are only a year old (ser #'s confirm this) and they were owned by an outdoor theater company. These were actually the WEATHERPROOFED version of the KF394, with some serious protection in front, so I dunno. I guess atmospheric salt is pretty permeable. (And yes, I've removed all the extra stuff. Those aluminum mesh screens sound terrible and add some weight as well.)

thanks.

please take pictures of the old diaphragm and the inside of the driver, post them here to see if I'm actually right, I cannot think about something else than corrosion at the moment but I still might be wrong. If it actually is some kind of salt, you need to find the source. Also, all salt residue has to be removed or it will start again. Do you live close to the sea (within 50km)?

I'll check the mids tonight & clean what I can without actually replacing them.

- Maybe I should desolder / remove them & clean those gaps as well?

I started a separate thread just about the white powder, as this was a serious emergency. A pic of the HF assembly is there, but here it is again:

Dropbox - BMS HF DRIVER - RESIDUE.jpg - Simplify your life

I'll take pics of the rest in a few minutes.

============================

As for salt water, I have no idea. I bought these second hand. They are only a year old (ser #'s confirm this) and they were owned by an outdoor theater company. These were actually the WEATHERPROOFED version of the KF394, with some serious protection in front, so I dunno. I guess atmospheric salt is pretty permeable. (And yes, I've removed all the extra stuff. Those aluminum mesh screens sound terrible and add some weight as well.)

Last edited:

Uhm, okay. That's not aluminium corrosion. That looks like thermal paste.

E: You can remove that with alcohol, it's messy to do that. If you don't use the driver for PA, you can leave that out for mounting the new diaphragm.

E: You can remove that with alcohol, it's messy to do that. If you don't use the driver for PA, you can leave that out for mounting the new diaphragm.

Last edited:

Umm... well..... thermal paste is basically what I was asking about.

I just cleaned it all off, from the exposed areas. but haven't actually removed the original diaphragm yet.

Of course I'm using it for a PA. What the heck can I do now?

Could I use electronics thermal paste, or maybe the stuff used for computer cpu's?

The latter could well be exactly the same stuff. (Actually, it does look & feel exactly the same as what you'd find on a 2 year old cpu.)

And like I asked originally, why would the stuff have seeped out all over the driver? See pic below, of how much was in-between the HF assembly and the MF assembly. Does this mean there isn't much left in the gap? That might explain the lousy sound I was getting.

Dropbox - BMS - Paste on mating surface..jpg - Simplify your life

I just cleaned it all off, from the exposed areas. but haven't actually removed the original diaphragm yet.

If you don't use the driver for PA, you can leave that out for mounting the new diaphragm.

Of course I'm using it for a PA. What the heck can I do now?

Could I use electronics thermal paste, or maybe the stuff used for computer cpu's?

The latter could well be exactly the same stuff. (Actually, it does look & feel exactly the same as what you'd find on a 2 year old cpu.)

And like I asked originally, why would the stuff have seeped out all over the driver? See pic below, of how much was in-between the HF assembly and the MF assembly. Does this mean there isn't much left in the gap? That might explain the lousy sound I was getting.

Dropbox - BMS - Paste on mating surface..jpg - Simplify your life

Last edited:

Wait a minute -

If it's thermal paste, then it's not being used like ferrofluid, as I first assumed. It's just applied to the mating surfaces, to help transfer heat to the cooling fins, correct?

If that's true, then there should be nothing in the coil gap at all, and I can definitely use cpu paste as a replacement.

(And it explains the "seepage," as there WAS none. That's exactly where it's supposed to be.)

---------------------------

ICG, does that sound correct?

If it's thermal paste, then it's not being used like ferrofluid, as I first assumed. It's just applied to the mating surfaces, to help transfer heat to the cooling fins, correct?

If that's true, then there should be nothing in the coil gap at all, and I can definitely use cpu paste as a replacement.

(And it explains the "seepage," as there WAS none. That's exactly where it's supposed to be.)

---------------------------

ICG, does that sound correct?

Last edited:

Umm... well..... thermal paste is basically what I was asking about.

I just cleaned it all off, from the exposed areas. but haven't actually removed the original diaphragm yet.

If you haven't removed it yet how on earth did you take the photo? 😕

Of course I'm using it for a PA. What the heck can I do now?

Could I use electronics thermal paste, or maybe the stuff used for computer cpu's?

The latter could well be exactly the same stuff. (Actually, it does look & feel exactly the same as what you'd find on a 2 year old cpu.)

This driver is actually used in hifi a lot more than in PA.

Yes, you can use the same thermal paste. It shouldn't make a big difference but since you've killed it once..

And like I asked originally, why would the stuff have seeped out all over the driver? See pic below, of how much was in-between the HF assembly and the MF assembly. Does this mean there isn't much left in the gap? That might explain the lousy sound I was getting.

It is quite unusual for a driver to have that in it, I haven't seen that ever before. Did you buy them used? The paste does not contribute much to the direct cooling of the tweeter coil but it could improve the heat transfer of the mid parts towards the back as that would increase the effective cooling surface. TBH, I'd mail BMS and ask them.

Wait aminute -

If it's thermal paste, then it's not being used like ferrofluid, as I first assumed. It's just applied to the mating surfaces, to help transfer heat to the cooling fins, correct?

If that's true, then there should be nothing in the coil gap at all, and I can definitely use cpu paste as a replacement.

(And it explains the "seepage," as there WAS none. That's exactly where it's supposed to be.)

---------------------------

ICG, does that sound correct?

Yes, that sounds perfectly reasonable. But it has to be put in there at some point. Besides it being WAAAY too much (the cooling gets then WORSE, not better), it would surely not look like that from the factory. It definitely does not belong in the air gap, it likely does not even belong in there at all.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Replacing BMS coaxial diaphram - tricky?