Caeles-special; an air-bearing turntable.

At ETF2017 I finally brought with me my TB3/1000-amplifiers. ETF (European Triode Festival) is a yearly event where about 150 DIY-audio-builders gather for 4 days. Although it really started as an European affair currently there are lots of Americans, Koreans and occasionally Japanese builders dropping in. You will encounter well-known names, founders of serious brands but especially great gear which is not your everyday hifi-set in main street. Amazing contraptions …….a lot of thought and work behind it……and lots of music and discussions alongside the out-of-these world audio-sets.

I’m visiting ETF for a couple of years now and like most of the attendees I bring along my latest projects; it’s what ETF makes ETF. But every year people ask me to bring “the BIG amplifiers”. In the picture below you can see the TB3/1000; there is a threat on this forum.

Picture old system

In 2017 it’s exactly what I did. Bringing 400 kgs of amps, 100 kgs of speakers and lots of extra stuff is a logistical challenge. Especially as the amps are on the second floor…..

Picture transport

Transport Netherlands – Denmark went OK and at ETF these amps were highly appreciated. Especially by Stephan. Stephan, also known as “Mr Measurement” (link Gecom) thought these amps were exactly the missing part in his system. He really liked the “effortless” power.

We made a quite unique swap: he got the TB3/1000 amp. I would receive a Caeles-turntable. Stephan is the designer of more audiogear but in my opinion the Caeles is his finest. Stephan lives by the motto “if you can measure it; you can improve it” and I KNOW that my TB3/1000 amps are at the right place. He will bring them to new heights. Literally because he made a special vertical rack for them.

Pictures of TB3/1000 at Stephan

I was allowed to choose how I would want that Caeles as normally these turntables are requested by extremely well-endowed persons who buy these more as an object than as serious audiogear. Stephan had delivered them in white ceramic finish but even in real leaf-gold (?!). I asked to have my Caeles as audiophile as possible; I was not looking for external perfection but for optimal musical delight. Stephan was very content with this order/request as now he could use the funny parts (his own words).

Picture of standard Caeles

The standard Caeles is an air-bearing turntable. The complete turntable can rest on automatically adjusted air-bladders to keep it perfectly horizontal. Caeles means “dweller in heaven” which might makes you think this is a light turntable. It is not……

My turntable is somewhat less neat than the commercial one BUT:

- has a far better (= lower) centre of gravity;

- has superior double air-bladders. To be more specific: low frequency, air levelling isolators normally used to be the perfect rest for very sensitive (measuring) equipment;

- is way more heavy due to material choice and construction;

- optimised in resonance-control (possible because of lesser important exterior);

- different motor housing;

The first/original Caeles is without the lower support but in an airtight and EMC-proof chamber so no external interferences can hamper playback. It just shows how focussed Stephan is with his Caeles-idea ! From that the “commercial” version was designed. And I can consider my Caeles as the max-pushed effort to get the most out of it....

Picture of the “original first”; still making its rotations at Stephan’s.

Some of the Caeles-parts were already available, some of them had to be ordered and on top of that I was send away on mission in the Middle - East for more than half a year. So this project took 2 years to finish but with great result.

Picture incoming parts

I had to tear down the audio-rack in my listening room. Not only because 2 of the shelves were empty now (the TB3/1000 amp was gone) but simply because I needed to make space for the turntable. It is HUGE !

Picture full set including TB3/1000

Picture torn-down frame including baseplate

Starting with a hardstone base-layer of 80 kgs.

The 50 kgs support is a 3-legged construction on spikes. The legs themselves are of made from 5 mm aluminium.

I filled the legs with special sandbags containing 75 kgs of fire-annealed sand (really dry; no chance for fungus).

The legs are closed with aluminium discs (1 cm thick).

Picture of flipped support (showing spikes)

Picture of sand filling

Picture of closing alu discs

Then the 3 turntable-pillars (containing the air levelling isolators [from now on called “airbladders”}) are positioned; again adding 30 kgs to the weight. The lower part is massive aluminium; the upper part contains the airbladder which can be covered with a shielding construction (see picture of that construction). One of the air-bladders fully exposed; one of the air-bladders partially covered; one of the air-bladders fully covered.

Picture of the pillars and different coverings.

The airbladder itself has a flat top. On top of each bladder are 2 concave stainless steel saucers containing a ceramic ball between them. This will act as a mechanical diode. The top of the upper stainless steel saucer will fit snugly in a special location in the next building part: the star-piece which acts like a sub-frame.

Picture of the RVS/ceramic top

The star-piece is a hefty 50 kg affair made of multi-layering of stainless steel – aluminium – plastic. It will bring the centre of gravity way down and will be the resting place for the backbone. In the arm-extensions of the star-piece you can see the locations where the stainless steel saucer ends up.

Picture of the star-piece

Because the star-piece had way larger vertical pillars then the original (to have the lowest centre of gravity as possible) I had to make a temporarily solution with some bricks. The special woodwork was not finished by then. Not nice to see but at least I could continue with the construction.

Picture of the star-piece in place

Then the building of the backbone and platter itself. This must first be constructed as a whole and then flipped-over on the sub-frame/star-piece.

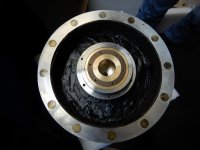

The core of the Caeles is of course the air-bearing. Normally this item as used for highest precision laser applications (tolerance is 0,1 micron)(link Eitzenberger). It is a bi-conical design so it cannot “tumble” and is perfectly capable of a vertical load of 160 kgs and a horizontal load of 25 kgs. The platter itself weighs “only” 30 kgs, so no issue. The bearing is maintenance free but needs a proper air supply.

Picture of the air-bearing

The air-bearing is fitted in the platter. That platter is a fully balanced affair from aluminium with brass inserts (preventing ringing and added weight). The inside of the platter is covered in bitumen.

It looks like there is a hole for the turntable-axle but in reality the axle is “air” and already fitted as seen in the picture. The hole in the middle will be used for inserting a mechanical diode (explained later).

Picture of the placed air bearing

The platter has a POM upper part; the spindle is totally free and not connected to the axle. For stability purposes the aluminium/brass lower part will act like a flywheel; mass is important for this kind of turntable. However heavy platters can store energy. A mechanical diode (precision axle ending with a ceramic ball on a Teflon thrust plate) will lead out any stored energy from the platter to the backbone. That axle would have been a serious turntable-axle in any other turntable…..here it is “just” a mechanical diode.

Picture of place diode

Picture of backbone with axle (mechanical diode)

The backbone is a construction of stainless steel and brass. On specific locations holes have been filled with lead ingots. Only 15 kgs….

Two outriggers are made from massive carbon. The spikes are made from different materials in order to eliminate resonances (brass, POM).

Picture of the backbone.

Backbone and platter flipped over on the sub-frame.

Picture of construction.

It start to look like a turntable…..but somewhat bigger.

In the meantime the wood- and metalwork is finished so I could take out those bricks.

Pictures (2x) of wood and metal work. Everything is soooo big….

But this looks way better; slabs of multiplex and granite instead of bricks

Picture of construction including wood/granite

The tonearm will be put on the tonearm base. That base is a perfectly milled out piece of brass with floating top. That top should be drilled out to the specific tonearm itself. Rega or SME cut-outs are the most well-known examples of these cuts-outs. However I have a ViV Rigid Float tonearm. This tonearm simply “sits” on top of the tonearm-base. The 2 kg spiked tonearm does not need a cut-out.

Stephan delivered a functional tonearm-base resonance-damper. It was a hefty piece of lead covered in bitumen. Although functional/effective this could be improved. Hans, a colleague of me (also audio-addict and ETF member), made a wonderful stack of bronze/lead milled down to perfection. It is almost a shame that his work is not to be seen when the Caeles actually works…..and hurrah…again 10kgs.

Pictures (2x) of tonearm-base and inserts

Picture of ViV

The motor-unit.

The fourth pillar of the original Caeles turntable is the pillar for the motor-unit. I have other plans with that fourth pillar AND Stephan had a FANTASTIC prototype motor-housing on his shelve. It was the prototype for a customer who wanted a serious upgrade of an original Mikro Seiki turntable. That worked……and the prototype housing (amazing over-the-top construction) was just gathering dust …..aaaarrgghhhh…..not acceptable. So I requested the non-original Caeles unit and to be honest Stephan was happily surprised as this casing was much more spacious and easier to work with. Gladly to be of assistance……

The original Caeles-pulley was beautiful fitted to the motor-housing by Hans. That pulley is huge. The idea behind it is that the motor itself can spin on much lower speed (and last for ages). The balanced pulley is made the same way as the platter: aluminium with inserts and the inside covered with anti-resonance stuff.

Picture of motor casing.

Picture of pulley

The motor itself is the trusty Dual EDS930; the direct-drive motor from the Dual 741Q. That turntable really set standards in tolerance, precision and consistency. In the 1980´s the Dual 741Q was the turntable to beat. It looked quite “plastic” but it was really well designed and the motor was the gem. As the 741Q was a directdrive-turntable the platter was directly on the motor-axle (exactly what the Caeles avoids…..because of the possibility of transferring motor-murmur to the vinyl). In fact: the EDS930-axle WAS the vinyl-spindle in the original Dual. The way the EDS930 is constructed allows me to put a huge pulley directly on it. There are numerous turntable-motors out there that would not take this load.

Luckily I scored a nice stash of NOS Dual EDS930’s to last a lifetime. Even the quality/check labels from November 1980 were there …..

Picture of EDS930 stash

The EDS930 is controlled by a quartz-driven PLL and needs of course a stable power supply. That is where Stephan really went all the way as he came up with a regulated battery power supply & charger. So in essence nicely separated from the mains.

From a huge stash of components he came up with a very successful re-use of a Wandel & Goltermann casing for the charger and batteries.

Picture of the power supply parts

Picture of the charger

Picture of the inscription

From the torn-down audiorack itself I made a motor & power supply support. Optimal re-use of stuff; even the slab of granite on top was a former speaker support.

In the meantime very slowly the air-components came in.

The compressor was quite easy. There are numerous oil-free compressors available. The challenge was the noise level…..but with a special outer casing this was brought down to an acceptable level. That compressor will be one storey down from the turntable so that distance will even bring the noise level more down. The real reason for the lower placement of the compressor is the oppression of water vapour which is bound to happen; even with moisture filters. Of course an air dryer in front of the compressor would result in absolute dry compressed air however these dryers are really noisy.

With a height difference, 3 successive air tanks and moisture filters this work great.

Pictures (2x) of the compressor

Picture of loose air stuff

The real challenge was the air filter itself. Because of the tolerance of the air bearing this filter is not really standard. It took some time before I received the combo of an 1 micron and 0,01 micron filter.

Also the safety valves (max air pressure to the air-bladders) were not standard.

Picture of filter

Air-work

The original Caeles uses tape or a string for the connection between pulley and platter. I use a Dyneema fishing wire. No slag, very strong and easy to knot.

Totally non standard to the Caeles are the 3 silicon oil filled dampers that are located between the star-piece and the support. All energy from platter etc is perfectly guided to the star-piece but it can not escape from there. However with these oil/paddle-contraptions all energy is simply smothered. Stephan had good results with this idea at his own Caeles but these never made it to the commercial versions.

Picture (2x) of oil dampeners

Also not standard is the use of an external axle. Instead that the pulley/motor is directly coupled to the platter itself, the pulley/motor is coupled to an external axle on the opposite side of the platter. And the platter simply happens to be in the middle and is only touched on 2 location on the rim. So a minute 2-sided load instead of a full 1-sided load

Picture of external axle (2x)

Stephan is very happy with my former TB3/1000 amplifiers. He’s enjoying them and with his expertise he has brought them to the next level. My design idea to build a tube-amplifier with sufficient power on demand without any stress and effortless music is still in place. But now optimised by Stephan; which means a lot.

It’s exactly what I do to his Caeles. The design criteria are true to the original; I simply made the circumstances optimal to perform. And this Caeles-Special PERFORMS; a heavenly dweller !

Picture Caeles

Heavenly does not mean light: 80 kgs stone base + 50 kgs tripod/support + 75 kgs sand + 3x10 kgs pillar and air-bladder + 50 kgs star-piece/sub-frame + 15 kgs backbone + 30 kgs platter + 10 kgs tonearm-base. That’s 340 kgs; and the motor-unit, arm and charger are not even included…..

A good swap; win-win for both.!

Enjoy the music,

Reinout

Picture system

At ETF2017 I finally brought with me my TB3/1000-amplifiers. ETF (European Triode Festival) is a yearly event where about 150 DIY-audio-builders gather for 4 days. Although it really started as an European affair currently there are lots of Americans, Koreans and occasionally Japanese builders dropping in. You will encounter well-known names, founders of serious brands but especially great gear which is not your everyday hifi-set in main street. Amazing contraptions …….a lot of thought and work behind it……and lots of music and discussions alongside the out-of-these world audio-sets.

I’m visiting ETF for a couple of years now and like most of the attendees I bring along my latest projects; it’s what ETF makes ETF. But every year people ask me to bring “the BIG amplifiers”. In the picture below you can see the TB3/1000; there is a threat on this forum.

Picture old system

In 2017 it’s exactly what I did. Bringing 400 kgs of amps, 100 kgs of speakers and lots of extra stuff is a logistical challenge. Especially as the amps are on the second floor…..

Picture transport

Transport Netherlands – Denmark went OK and at ETF these amps were highly appreciated. Especially by Stephan. Stephan, also known as “Mr Measurement” (link Gecom) thought these amps were exactly the missing part in his system. He really liked the “effortless” power.

We made a quite unique swap: he got the TB3/1000 amp. I would receive a Caeles-turntable. Stephan is the designer of more audiogear but in my opinion the Caeles is his finest. Stephan lives by the motto “if you can measure it; you can improve it” and I KNOW that my TB3/1000 amps are at the right place. He will bring them to new heights. Literally because he made a special vertical rack for them.

Pictures of TB3/1000 at Stephan

I was allowed to choose how I would want that Caeles as normally these turntables are requested by extremely well-endowed persons who buy these more as an object than as serious audiogear. Stephan had delivered them in white ceramic finish but even in real leaf-gold (?!). I asked to have my Caeles as audiophile as possible; I was not looking for external perfection but for optimal musical delight. Stephan was very content with this order/request as now he could use the funny parts (his own words).

Picture of standard Caeles

The standard Caeles is an air-bearing turntable. The complete turntable can rest on automatically adjusted air-bladders to keep it perfectly horizontal. Caeles means “dweller in heaven” which might makes you think this is a light turntable. It is not……

My turntable is somewhat less neat than the commercial one BUT:

- has a far better (= lower) centre of gravity;

- has superior double air-bladders. To be more specific: low frequency, air levelling isolators normally used to be the perfect rest for very sensitive (measuring) equipment;

- is way more heavy due to material choice and construction;

- optimised in resonance-control (possible because of lesser important exterior);

- different motor housing;

The first/original Caeles is without the lower support but in an airtight and EMC-proof chamber so no external interferences can hamper playback. It just shows how focussed Stephan is with his Caeles-idea ! From that the “commercial” version was designed. And I can consider my Caeles as the max-pushed effort to get the most out of it....

Picture of the “original first”; still making its rotations at Stephan’s.

Some of the Caeles-parts were already available, some of them had to be ordered and on top of that I was send away on mission in the Middle - East for more than half a year. So this project took 2 years to finish but with great result.

Picture incoming parts

I had to tear down the audio-rack in my listening room. Not only because 2 of the shelves were empty now (the TB3/1000 amp was gone) but simply because I needed to make space for the turntable. It is HUGE !

Picture full set including TB3/1000

Picture torn-down frame including baseplate

Starting with a hardstone base-layer of 80 kgs.

The 50 kgs support is a 3-legged construction on spikes. The legs themselves are of made from 5 mm aluminium.

I filled the legs with special sandbags containing 75 kgs of fire-annealed sand (really dry; no chance for fungus).

The legs are closed with aluminium discs (1 cm thick).

Picture of flipped support (showing spikes)

Picture of sand filling

Picture of closing alu discs

Then the 3 turntable-pillars (containing the air levelling isolators [from now on called “airbladders”}) are positioned; again adding 30 kgs to the weight. The lower part is massive aluminium; the upper part contains the airbladder which can be covered with a shielding construction (see picture of that construction). One of the air-bladders fully exposed; one of the air-bladders partially covered; one of the air-bladders fully covered.

Picture of the pillars and different coverings.

The airbladder itself has a flat top. On top of each bladder are 2 concave stainless steel saucers containing a ceramic ball between them. This will act as a mechanical diode. The top of the upper stainless steel saucer will fit snugly in a special location in the next building part: the star-piece which acts like a sub-frame.

Picture of the RVS/ceramic top

The star-piece is a hefty 50 kg affair made of multi-layering of stainless steel – aluminium – plastic. It will bring the centre of gravity way down and will be the resting place for the backbone. In the arm-extensions of the star-piece you can see the locations where the stainless steel saucer ends up.

Picture of the star-piece

Because the star-piece had way larger vertical pillars then the original (to have the lowest centre of gravity as possible) I had to make a temporarily solution with some bricks. The special woodwork was not finished by then. Not nice to see but at least I could continue with the construction.

Picture of the star-piece in place

Then the building of the backbone and platter itself. This must first be constructed as a whole and then flipped-over on the sub-frame/star-piece.

The core of the Caeles is of course the air-bearing. Normally this item as used for highest precision laser applications (tolerance is 0,1 micron)(link Eitzenberger). It is a bi-conical design so it cannot “tumble” and is perfectly capable of a vertical load of 160 kgs and a horizontal load of 25 kgs. The platter itself weighs “only” 30 kgs, so no issue. The bearing is maintenance free but needs a proper air supply.

Picture of the air-bearing

The air-bearing is fitted in the platter. That platter is a fully balanced affair from aluminium with brass inserts (preventing ringing and added weight). The inside of the platter is covered in bitumen.

It looks like there is a hole for the turntable-axle but in reality the axle is “air” and already fitted as seen in the picture. The hole in the middle will be used for inserting a mechanical diode (explained later).

Picture of the placed air bearing

The platter has a POM upper part; the spindle is totally free and not connected to the axle. For stability purposes the aluminium/brass lower part will act like a flywheel; mass is important for this kind of turntable. However heavy platters can store energy. A mechanical diode (precision axle ending with a ceramic ball on a Teflon thrust plate) will lead out any stored energy from the platter to the backbone. That axle would have been a serious turntable-axle in any other turntable…..here it is “just” a mechanical diode.

Picture of place diode

Picture of backbone with axle (mechanical diode)

The backbone is a construction of stainless steel and brass. On specific locations holes have been filled with lead ingots. Only 15 kgs….

Two outriggers are made from massive carbon. The spikes are made from different materials in order to eliminate resonances (brass, POM).

Picture of the backbone.

Backbone and platter flipped over on the sub-frame.

Picture of construction.

It start to look like a turntable…..but somewhat bigger.

In the meantime the wood- and metalwork is finished so I could take out those bricks.

Pictures (2x) of wood and metal work. Everything is soooo big….

But this looks way better; slabs of multiplex and granite instead of bricks

Picture of construction including wood/granite

The tonearm will be put on the tonearm base. That base is a perfectly milled out piece of brass with floating top. That top should be drilled out to the specific tonearm itself. Rega or SME cut-outs are the most well-known examples of these cuts-outs. However I have a ViV Rigid Float tonearm. This tonearm simply “sits” on top of the tonearm-base. The 2 kg spiked tonearm does not need a cut-out.

Stephan delivered a functional tonearm-base resonance-damper. It was a hefty piece of lead covered in bitumen. Although functional/effective this could be improved. Hans, a colleague of me (also audio-addict and ETF member), made a wonderful stack of bronze/lead milled down to perfection. It is almost a shame that his work is not to be seen when the Caeles actually works…..and hurrah…again 10kgs.

Pictures (2x) of tonearm-base and inserts

Picture of ViV

The motor-unit.

The fourth pillar of the original Caeles turntable is the pillar for the motor-unit. I have other plans with that fourth pillar AND Stephan had a FANTASTIC prototype motor-housing on his shelve. It was the prototype for a customer who wanted a serious upgrade of an original Mikro Seiki turntable. That worked……and the prototype housing (amazing over-the-top construction) was just gathering dust …..aaaarrgghhhh…..not acceptable. So I requested the non-original Caeles unit and to be honest Stephan was happily surprised as this casing was much more spacious and easier to work with. Gladly to be of assistance……

The original Caeles-pulley was beautiful fitted to the motor-housing by Hans. That pulley is huge. The idea behind it is that the motor itself can spin on much lower speed (and last for ages). The balanced pulley is made the same way as the platter: aluminium with inserts and the inside covered with anti-resonance stuff.

Picture of motor casing.

Picture of pulley

The motor itself is the trusty Dual EDS930; the direct-drive motor from the Dual 741Q. That turntable really set standards in tolerance, precision and consistency. In the 1980´s the Dual 741Q was the turntable to beat. It looked quite “plastic” but it was really well designed and the motor was the gem. As the 741Q was a directdrive-turntable the platter was directly on the motor-axle (exactly what the Caeles avoids…..because of the possibility of transferring motor-murmur to the vinyl). In fact: the EDS930-axle WAS the vinyl-spindle in the original Dual. The way the EDS930 is constructed allows me to put a huge pulley directly on it. There are numerous turntable-motors out there that would not take this load.

Luckily I scored a nice stash of NOS Dual EDS930’s to last a lifetime. Even the quality/check labels from November 1980 were there …..

Picture of EDS930 stash

The EDS930 is controlled by a quartz-driven PLL and needs of course a stable power supply. That is where Stephan really went all the way as he came up with a regulated battery power supply & charger. So in essence nicely separated from the mains.

From a huge stash of components he came up with a very successful re-use of a Wandel & Goltermann casing for the charger and batteries.

Picture of the power supply parts

Picture of the charger

Picture of the inscription

From the torn-down audiorack itself I made a motor & power supply support. Optimal re-use of stuff; even the slab of granite on top was a former speaker support.

In the meantime very slowly the air-components came in.

The compressor was quite easy. There are numerous oil-free compressors available. The challenge was the noise level…..but with a special outer casing this was brought down to an acceptable level. That compressor will be one storey down from the turntable so that distance will even bring the noise level more down. The real reason for the lower placement of the compressor is the oppression of water vapour which is bound to happen; even with moisture filters. Of course an air dryer in front of the compressor would result in absolute dry compressed air however these dryers are really noisy.

With a height difference, 3 successive air tanks and moisture filters this work great.

Pictures (2x) of the compressor

Picture of loose air stuff

The real challenge was the air filter itself. Because of the tolerance of the air bearing this filter is not really standard. It took some time before I received the combo of an 1 micron and 0,01 micron filter.

Also the safety valves (max air pressure to the air-bladders) were not standard.

Picture of filter

Air-work

The original Caeles uses tape or a string for the connection between pulley and platter. I use a Dyneema fishing wire. No slag, very strong and easy to knot.

Totally non standard to the Caeles are the 3 silicon oil filled dampers that are located between the star-piece and the support. All energy from platter etc is perfectly guided to the star-piece but it can not escape from there. However with these oil/paddle-contraptions all energy is simply smothered. Stephan had good results with this idea at his own Caeles but these never made it to the commercial versions.

Picture (2x) of oil dampeners

Also not standard is the use of an external axle. Instead that the pulley/motor is directly coupled to the platter itself, the pulley/motor is coupled to an external axle on the opposite side of the platter. And the platter simply happens to be in the middle and is only touched on 2 location on the rim. So a minute 2-sided load instead of a full 1-sided load

Picture of external axle (2x)

Stephan is very happy with my former TB3/1000 amplifiers. He’s enjoying them and with his expertise he has brought them to the next level. My design idea to build a tube-amplifier with sufficient power on demand without any stress and effortless music is still in place. But now optimised by Stephan; which means a lot.

It’s exactly what I do to his Caeles. The design criteria are true to the original; I simply made the circumstances optimal to perform. And this Caeles-Special PERFORMS; a heavenly dweller !

Picture Caeles

Heavenly does not mean light: 80 kgs stone base + 50 kgs tripod/support + 75 kgs sand + 3x10 kgs pillar and air-bladder + 50 kgs star-piece/sub-frame + 15 kgs backbone + 30 kgs platter + 10 kgs tonearm-base. That’s 340 kgs; and the motor-unit, arm and charger are not even included…..

A good swap; win-win for both.!

Enjoy the music,

Reinout

Picture system

Attachments

Last edited:

added pictures

sorry for splashing all the pictures at the end. I can not make it work to get the pictures INSIDE the text. It should be sooooooooooooooo easy (like almost all other forums) to have after each download the option "in text" or "at the end"....

sorry for splashing all the pictures at the end. I can not make it work to get the pictures INSIDE the text. It should be sooooooooooooooo easy (like almost all other forums) to have after each download the option "in text" or "at the end"....

Attachments

-

DSCN0274.jpg391.9 KB · Views: 180

DSCN0274.jpg391.9 KB · Views: 180 -

DSCN0275.jpg393.7 KB · Views: 189

DSCN0275.jpg393.7 KB · Views: 189 -

DSCN0456.JPG431.3 KB · Views: 150

DSCN0456.JPG431.3 KB · Views: 150 -

DSCN0457.JPG441.2 KB · Views: 162

DSCN0457.JPG441.2 KB · Views: 162 -

DSCN0458.JPG450.6 KB · Views: 164

DSCN0458.JPG450.6 KB · Views: 164 -

DSCN0459.JPG443 KB · Views: 180

DSCN0459.JPG443 KB · Views: 180 -

DSCN0460.JPG430 KB · Views: 215

DSCN0460.JPG430 KB · Views: 215 -

DSCN0366.JPG488.7 KB · Views: 228

DSCN0366.JPG488.7 KB · Views: 228 -

DSCN0372.JPG725.3 KB · Views: 197

DSCN0372.JPG725.3 KB · Views: 197 -

DSCN0411.JPG731 KB · Views: 266

DSCN0411.JPG731 KB · Views: 266

added pictures

More pictures

More pictures

Attachments

-

DSCN0428.JPG491.9 KB · Views: 183

DSCN0428.JPG491.9 KB · Views: 183 -

DSCN0391.JPG357.9 KB · Views: 191

DSCN0391.JPG357.9 KB · Views: 191 -

DSCN0426.JPG579.6 KB · Views: 197

DSCN0426.JPG579.6 KB · Views: 197 -

Bearing.jpg583 KB · Views: 189

Bearing.jpg583 KB · Views: 189 -

DSCN0431.JPG405.1 KB · Views: 173

DSCN0431.JPG405.1 KB · Views: 173 -

DSCN0462.JPG439.6 KB · Views: 171

DSCN0462.JPG439.6 KB · Views: 171 -

DSCN0475.JPG445 KB · Views: 188

DSCN0475.JPG445 KB · Views: 188 -

DSCN0474.JPG496 KB · Views: 184

DSCN0474.JPG496 KB · Views: 184 -

DSCN0500.JPG469.4 KB · Views: 213

DSCN0500.JPG469.4 KB · Views: 213 -

DSCN0510.JPG473 KB · Views: 191

DSCN0510.JPG473 KB · Views: 191

added pictures

more pictures

more pictures

Attachments

-

DSCN0560.JPG384.3 KB · Views: 130

DSCN0560.JPG384.3 KB · Views: 130 -

DSCN0563.JPG369.7 KB · Views: 155

DSCN0563.JPG369.7 KB · Views: 155 -

DSCN0230.JPG699.6 KB · Views: 143

DSCN0230.JPG699.6 KB · Views: 143 -

DSCN0596.JPG573.8 KB · Views: 136

DSCN0596.JPG573.8 KB · Views: 136 -

DSCN0597.JPG598.3 KB · Views: 130

DSCN0597.JPG598.3 KB · Views: 130 -

DSCN0598.JPG375.2 KB · Views: 138

DSCN0598.JPG375.2 KB · Views: 138 -

DSCN0608.JPG529.3 KB · Views: 130

DSCN0608.JPG529.3 KB · Views: 130 -

DSCN0614.JPG476 KB · Views: 142

DSCN0614.JPG476 KB · Views: 142 -

DSCN0619.JPG520.4 KB · Views: 162

DSCN0619.JPG520.4 KB · Views: 162

added pictures

more pictures

more pictures

Attachments

-

DSCN0409.JPG346.4 KB · Views: 148

DSCN0409.JPG346.4 KB · Views: 148 -

DSCN0406.JPG354.7 KB · Views: 163

DSCN0406.JPG354.7 KB · Views: 163 -

DSCN1483.JPG298.3 KB · Views: 158

DSCN1483.JPG298.3 KB · Views: 158 -

DSCN1484.JPG412.2 KB · Views: 141

DSCN1484.JPG412.2 KB · Views: 141 -

DSCN0621.JPG333.3 KB · Views: 136

DSCN0621.JPG333.3 KB · Views: 136 -

DSCN1509.JPG132.8 KB · Views: 133

DSCN1509.JPG132.8 KB · Views: 133 -

DSCN1510.JPG161.6 KB · Views: 152

DSCN1510.JPG161.6 KB · Views: 152 -

DSCN1512.JPG175.7 KB · Views: 156

DSCN1512.JPG175.7 KB · Views: 156 -

InkedDSCN1522_LI.jpg803.1 KB · Views: 148

InkedDSCN1522_LI.jpg803.1 KB · Views: 148 -

DSCN1531.JPG207.1 KB · Views: 145

DSCN1531.JPG207.1 KB · Views: 145

Caeles at work....

And it's great (and somewhat different) to use this turntable.

First getting the correct pressure. And suddenly the platter is "floating" (giving the platter a simple push will make this go on almost forever....).

Then get the air-bladders pressurised; the complete structure lifts some millimeters and is completely decoupled.

After that you can simply turn vinyl you used to do with more conventional turntables.

Enjoy the music,

Reinout

And it's great (and somewhat different) to use this turntable.

First getting the correct pressure. And suddenly the platter is "floating" (giving the platter a simple push will make this go on almost forever....).

Then get the air-bladders pressurised; the complete structure lifts some millimeters and is completely decoupled.

After that you can simply turn vinyl you used to do with more conventional turntables.

Enjoy the music,

Reinout

Attachments

Well that rotation is nice and stable now!

How does its stability compare with common cutting lathes?

How does its stability compare with common cutting lathes?

Good morning Super10018,

you're right: that's the air-bearing.

It's a modified Eitzenberger ( Luftlagerrundtische ).

The modification is mainly the choice of material (brass instead of stainless steel)

It is a pleasure to use: the platter simply "floats" and the used air does not make funny hissing noises. You can not hear this bearing in action although you continiously lose air.

This bearing is a bi-conical design. So it is not just a flat plate/platter pushed upwards but double conical shape that maintains its position by a thin layer of air. It can not "tumble".

Most of the commercial air bearing turntables only push the platter up (vertical air bearing) but in the horizontal plain it is still mechanical coupled where you loose that special complete isolation by air. The Eitzenberger uses a more complex form inside the bearing to make air-decoupling possible in both the vertical and horizontal planes.

Regards, Reinout

you're right: that's the air-bearing.

It's a modified Eitzenberger ( Luftlagerrundtische ).

The modification is mainly the choice of material (brass instead of stainless steel)

It is a pleasure to use: the platter simply "floats" and the used air does not make funny hissing noises. You can not hear this bearing in action although you continiously lose air.

This bearing is a bi-conical design. So it is not just a flat plate/platter pushed upwards but double conical shape that maintains its position by a thin layer of air. It can not "tumble".

Most of the commercial air bearing turntables only push the platter up (vertical air bearing) but in the horizontal plain it is still mechanical coupled where you loose that special complete isolation by air. The Eitzenberger uses a more complex form inside the bearing to make air-decoupling possible in both the vertical and horizontal planes.

Regards, Reinout

Attachments

Again good morning Super10018,

That VIVLab Rigid Float tonearm works very nice (Rigid Float/Ha (7”/ 9”/ 13”) ). I use the 9" version but because of the location/placement it is effectively longer than other 9" arms.

I use very light Van Den Hul Colibri cartridges and normally i'm stuck to light to light/mid-weight tonearms. But the Rigid Float simply accepts everything. Also DL103's are no problem. The mechanical contrast between the compliance of the Colibri and the 103 is huge but because of the tonearm construction (especially the magnetic oil !) evey cartridge is acceptable.

Set up is easy. I can leave my Feickert Protractor in the box as this Rigid Float uses a totally different set up. And because of that set up and the construction of the tonearm there is no off-set, no anti-skating. Changing a cartridge takes a minute; maximum. If the overhang is different you simply pick up the 2 kgs tonearm and move it some millimeters along a prescribed line.

Very happy with this tonearm. Currently there is a carbon version available but i don't have experience with that newer (and much more expensive) version.

Regards,

Reinout

That VIVLab Rigid Float tonearm works very nice (Rigid Float/Ha (7”/ 9”/ 13”) ). I use the 9" version but because of the location/placement it is effectively longer than other 9" arms.

I use very light Van Den Hul Colibri cartridges and normally i'm stuck to light to light/mid-weight tonearms. But the Rigid Float simply accepts everything. Also DL103's are no problem. The mechanical contrast between the compliance of the Colibri and the 103 is huge but because of the tonearm construction (especially the magnetic oil !) evey cartridge is acceptable.

Set up is easy. I can leave my Feickert Protractor in the box as this Rigid Float uses a totally different set up. And because of that set up and the construction of the tonearm there is no off-set, no anti-skating. Changing a cartridge takes a minute; maximum. If the overhang is different you simply pick up the 2 kgs tonearm and move it some millimeters along a prescribed line.

Very happy with this tonearm. Currently there is a carbon version available but i don't have experience with that newer (and much more expensive) version.

Regards,

Reinout

Attachments

Very nice dedication to the art of spinning a record !

How much air pressure is required for the platter bearing and its load limit range ?

I have built a few of these, (vertical air pressure direction only) and have to use the typical oil sintered bearing for horizontal pull of the belt.

Regards

David

How much air pressure is required for the platter bearing and its load limit range ?

I have built a few of these, (vertical air pressure direction only) and have to use the typical oil sintered bearing for horizontal pull of the belt.

Regards

David

Hi Reinout

It looks like a very nice air bearing. I tried to build my own air bearing table but failed. I used 25 mm Oav Roller air bearing. It has Radial Load Max 28 lbs and Axial Load Max 155 lbs. The reasons I failed were I don't have enough air supply even I met minimum air supply and didn't have a good machine shop to do precision parts for me. One day, I may try it again.

For the arm, I am glad that you like the arm. However, its design principle is completely wrong. They eliminate the off set angle to avoid skating force. In fact, skating force still exists for their arms. They completely ignore tracking errors. I can't agree with that.

Jim

It looks like a very nice air bearing. I tried to build my own air bearing table but failed. I used 25 mm Oav Roller air bearing. It has Radial Load Max 28 lbs and Axial Load Max 155 lbs. The reasons I failed were I don't have enough air supply even I met minimum air supply and didn't have a good machine shop to do precision parts for me. One day, I may try it again.

For the arm, I am glad that you like the arm. However, its design principle is completely wrong. They eliminate the off set angle to avoid skating force. In fact, skating force still exists for their arms. They completely ignore tracking errors. I can't agree with that.

Jim

Last edited:

Good evening David,

the vertical load can be 160 kgs on this bearing; the horizontal load 25 kgs.

It needs about 20 l/min to "float".

Regards,

Reinout

the vertical load can be 160 kgs on this bearing; the horizontal load 25 kgs.

It needs about 20 l/min to "float".

Regards,

Reinout

Good evening Jim,

the data for your OAV Roller air bearing are not that dissimilar to my requirements. And 20 l/min, my requirements, is not that hard to reach.

Of course it must be a clean compressor (so please an oil-free version) and the working cycle should be 100% (so the possibility to remain always on). This excludes most of the air/spray-paint compressors but there are enough optoins out there.

I only used a sequence of air tanks to get rid of the pushing of air out of the compressor so the air flow at the final outlet is really nice and stabil.

Of course the Rigid Float isn't the perfect tonearm. Any swing-version has errors. To be honest a tangential tonearm should get the best results but making such a contraption isn't easy. And for me this air-bearing turntable was my first introduction to pneumatics and than also going for an air bearing tangential was simply pushing my luck.....

Yes of course these Rigid Float do have some side force. But it is minute compared to standard tonearms.

For me this works but i don't know it is my "final" tonearm. But currently this Rigid Float is wonderful in accepting a large range of cartridges. Much fun ahead !

Regards, Reinout

the data for your OAV Roller air bearing are not that dissimilar to my requirements. And 20 l/min, my requirements, is not that hard to reach.

Of course it must be a clean compressor (so please an oil-free version) and the working cycle should be 100% (so the possibility to remain always on). This excludes most of the air/spray-paint compressors but there are enough optoins out there.

I only used a sequence of air tanks to get rid of the pushing of air out of the compressor so the air flow at the final outlet is really nice and stabil.

Of course the Rigid Float isn't the perfect tonearm. Any swing-version has errors. To be honest a tangential tonearm should get the best results but making such a contraption isn't easy. And for me this air-bearing turntable was my first introduction to pneumatics and than also going for an air bearing tangential was simply pushing my luck.....

Yes of course these Rigid Float do have some side force. But it is minute compared to standard tonearms.

For me this works but i don't know it is my "final" tonearm. But currently this Rigid Float is wonderful in accepting a large range of cartridges. Much fun ahead !

Regards, Reinout

Attachments

Last edited:

Very nice dedication to the art of spinning a record !

How much air pressure is required for the platter bearing and its load limit range ?

I have built a few of these, (vertical air pressure direction only) and have to use the typical oil sintered bearing for horizontal pull of the belt.

Regards

David

Hi David,

I think its pressure requirement is about 5 bar or 75 psi. Pressure is not problem but flow rate is. It may require high flow rate. Most of air compressor will not meet its requirement unless you go real big one. The big one may make more noise and needs more room.

I have been looking an air spindle on eBay for a while. A passive air spindle will do the job.

Jim

Hi Reinout,

Thanks for the info!

I would like to learn the construction of arm base on the table. Is possible to share the detail?

Jim

Thanks for the info!

I would like to learn the construction of arm base on the table. Is possible to share the detail?

Jim

base

The backbone is a sandwich of Stainless Steel and brass; bolted together.

Sticking outside this sandwich are the 2 (solid) carbon outriggers.

There are some holes drilled in the backbone and later filled with lead.....all in order to undermine resonances.

On one side of the backbone the air bearing is bolted. On the other side a "tower" is placed which will act as the tonearm-base.

Regards,

Reinout

The backbone is a sandwich of Stainless Steel and brass; bolted together.

Sticking outside this sandwich are the 2 (solid) carbon outriggers.

There are some holes drilled in the backbone and later filled with lead.....all in order to undermine resonances.

On one side of the backbone the air bearing is bolted. On the other side a "tower" is placed which will act as the tonearm-base.

Regards,

Reinout

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Caeles-special; an air-bearing turntable