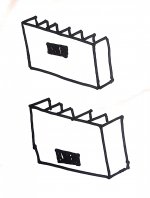

In principle centered is better but centered horizontally and somewhat shifted vertically as in your second option is practically same, since heatsink main body (not the fins) is usually quite thick.

It would be more critical if heatsink were, say,an aluminum back panel which would be much thinner, say 1 or 1.5 mm thick, but I guess your extruded heatsink is at least 2.5 mm thick, a big difference.

It would be more critical if heatsink were, say,an aluminum back panel which would be much thinner, say 1 or 1.5 mm thick, but I guess your extruded heatsink is at least 2.5 mm thick, a big difference.

Thanks a lot for detail information

In principle centered is better but centered horizontally and somewhat shifted vertically as in your second option is practically same, since heatsink main body (not the fins) is usually quite thick.

It would be more critical if heatsink were, say,an aluminum back panel which would be much thinner, say 1 or 1.5 mm thick, but I guess your extruded heatsink is at least 2.5 mm thick, a big difference.

Thank you

🙂

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Effective IC position on Heat sink