Hi,

I want to design one of the two types for the JBL 2446.

The one I choose depends on size.

Do I have to incorporate the 10° exit angle of the driver into the design?

I know how to work with Hornresp, but I'm not an expert.

What do you use as a driver to simulate the JBL 2446?

Rob

I want to design one of the two types for the JBL 2446.

The one I choose depends on size.

Do I have to incorporate the 10° exit angle of the driver into the design?

I know how to work with Hornresp, but I'm not an expert.

What do you use as a driver to simulate the JBL 2446?

Rob

Rob,

Do some research on Dr. Bruce Edgar with regards to horn design. He has years of experience with horn design and published many articles. He likes tractrix profile for midrange duty best although you can find proponents for both horn profiles. Tractrix will in general will be deeper while Le Cleach have a much wider mouth with less depth. I use field coil converted Jbl 2441 drivers myself with beryllium diaphragms on 250 hz. tractrix wood horns. I know titanium diaphragms ca be hard on the ears, aluminum would be better. The 2446 driver uses the same diaphragms as the 2445 driver so you may be able to substitute the 2445 driver in hornresp, but I don't know for sure. Good luck with your project.

Do some research on Dr. Bruce Edgar with regards to horn design. He has years of experience with horn design and published many articles. He likes tractrix profile for midrange duty best although you can find proponents for both horn profiles. Tractrix will in general will be deeper while Le Cleach have a much wider mouth with less depth. I use field coil converted Jbl 2441 drivers myself with beryllium diaphragms on 250 hz. tractrix wood horns. I know titanium diaphragms ca be hard on the ears, aluminum would be better. The 2446 driver uses the same diaphragms as the 2445 driver so you may be able to substitute the 2445 driver in hornresp, but I don't know for sure. Good luck with your project.

I can't tolerate the high frequency beaming of a Le Cleach horn and much prefer an OS CD waveguide.

^^ Neither do I. Same with trax horns, and I spent a very large sum of money getting some large traxs turned up on a lathe and hated them.

SEOS WGs are available from horns.pl as well.

Oh, and Rob, ditch the Ti phrams as they're useless above 8k or so and generally sound awful. Radian Al units are nice but have about the same HF limit. I was never tempted to try the Be units as they came after I'd moved into different areas and I never really liked the TAD Be units I had at one stage.

SEOS WGs are available from horns.pl as well.

Oh, and Rob, ditch the Ti phrams as they're useless above 8k or so and generally sound awful. Radian Al units are nice but have about the same HF limit. I was never tempted to try the Be units as they came after I'd moved into different areas and I never really liked the TAD Be units I had at one stage.

Hi Hottatto,

I'm gonna explore Bruce Edgar and find out if I find the answers.

Brett I know the Horns.pl company but I have a CNC router and want to build them myself.

Curruntly I run a pair of JBL 2445 on a set of Uchi A-290 horns and I like it very much.

But I want to compare them with Tractrix and Le Cleach round horns.

Also I know the difference between the two except in sound.

But first I have to design them in Hornresp and export the horn flare.

So my questions are still standing.

Do I have to incorporate the 10 degrees exit angle into the design of the horns.

And is there an example from a JBL 24** driver I can use in Hornresp.

Rob

I'm gonna explore Bruce Edgar and find out if I find the answers.

Brett I know the Horns.pl company but I have a CNC router and want to build them myself.

Curruntly I run a pair of JBL 2445 on a set of Uchi A-290 horns and I like it very much.

But I want to compare them with Tractrix and Le Cleach round horns.

Also I know the difference between the two except in sound.

But first I have to design them in Hornresp and export the horn flare.

So my questions are still standing.

Do I have to incorporate the 10 degrees exit angle into the design of the horns.

And is there an example from a JBL 24** driver I can use in Hornresp.

Rob

Do I have to incorporate the 10 degrees exit angle into the design of the horns.

Rob

I do in the horns I design, using BMS compression drivers. It's best practice to do so. The two approaches I have used are connecting the two angles with a large constant radius (Hughes) or designing a large OS horn. Geddes has written much on this. A large mouth rollover, either constant radius or OS is very beneficial too. Take the flair out to 180 degrees if aesthetically acceptable.

You'll find some inspiration for CNC'd horns at A for Ara (@a.for.ara) • Instagram photos and videos These horns use both the approaches mentioned above. I've not noticed any sonic signature I could attribute to the use of OS or constant radius transitions, both work very well.

Rob,

It is nice to have a CNC router as you have the ability to experiment with different horn sizes / profiles. Looking at my tractrix horns, it seems to follow the internal angle of the driver Ideally, you wold want to crossover the mid horn at about 500hz. on the low end and 5K to 6K on the top end to an upper midrange horn or a good tweeter. I use a TAD ET-703 tweeter ( $$$$ and near unobtanium ) but the Fostex T500AMK2 is also excellent.

It is nice to have a CNC router as you have the ability to experiment with different horn sizes / profiles. Looking at my tractrix horns, it seems to follow the internal angle of the driver Ideally, you wold want to crossover the mid horn at about 500hz. on the low end and 5K to 6K on the top end to an upper midrange horn or a good tweeter. I use a TAD ET-703 tweeter ( $$$$ and near unobtanium ) but the Fostex T500AMK2 is also excellent.

Here is what some other horn "nuts" have built !!!

GoodSoundClub - Romy the Cat's Audio Site - Not exactly flat to 18Hz...

GoodSoundClub - Romy the Cat's Audio Site - Not exactly flat to 18Hz...

yea, maybe a decade on tractrix, like 500-5khz, maybe.

Thanks for the tip on titanium, I've been curious if my 2431's (aluminum) would work out, and they have.

+1 on mouth round over

Thanks for the tip on titanium, I've been curious if my 2431's (aluminum) would work out, and they have.

+1 on mouth round over

Before I settled on Tractrix for my 500-20k 1" exit, I built a few other profiles to listen to. I tried OS , and I believe exponential. The Tractrix was much better so that's what I went with. Another issue with the le cleach is the huge round over has an impact on the center to center spacing one can achieve. For the exit angle to match the throat angle I simply drew a line at 6 degrees (that's the exit angle of my driver) and laid it down in the cad software to where it is tangent to the curve. In this way you actually have a conical expansion for the first couple of inches then flaring out Tractrix after that. It is thought to be important to match those angles.

As these are a 'constant diffraction' horn, there may not be an ideal as such. However, IIRC JMLC has suggested using a roundover to match a driver.Do I have to incorporate the 10 degrees exit angle into the design of the horns.

Broadly speaking, make the cutoff frequency an octave below the intended band.And is there an example from a JBL 24** driver I can use in Hornresp.

If you are using these for directivity purposes (I suspect not) then you don't need the specific driver in hornresp.

Yes my horn will be circular.Is your horn circular? I know practical way to design for particular driver .

Rob

Here you go, the v2 of the JMLC made by the man himself. You can input driver angle I believe.

I had some CNC horns made a while ago. I used the spreadshsheet, took the list of numbers, and in Solid Works (Illustrator worked too I believe) used them to input the curvature. We then revolved it into a solid object, split the layers and cut 18mm birch in individual rings. But if it will fit on your CNC in one all the better.

Dropbox - JMLC_horn_v2.xlsx

Let me know how it goes.

I had some CNC horns made a while ago. I used the spreadshsheet, took the list of numbers, and in Solid Works (Illustrator worked too I believe) used them to input the curvature. We then revolved it into a solid object, split the layers and cut 18mm birch in individual rings. But if it will fit on your CNC in one all the better.

Dropbox - JMLC_horn_v2.xlsx

Let me know how it goes.

Hi TimbreAudio,

It's exact the way I work only export data from Hornresp.

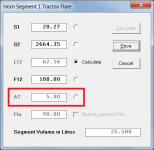

I found out that in Hornresp you can put the half angle for JMLC horns and you can read the angle for tractrix.

Rob

It's exact the way I work only export data from Hornresp.

I found out that in Hornresp you can put the half angle for JMLC horns and you can read the angle for tractrix.

Rob

First open the book of Le cláec'h Acoustical horns and id waveguideswww.rintelen.ch/download/JMMLC_horns_lecture_etf10.pdf

page86 . He traced several flares all of same Fc . You notice that all these curves follow the initial about 450mm the same exponential flare. The diameter at this point is about 5 times the throat , more exactly 4.81 times where the exponential reaches it's Fc quarter wavelength . So , whatever is your choise you have to built first this exponential quarter wavelength . Once built and the driver installed , glue with hot gun trapizoidal shape long pieces of cardboard 2mm on the mouth overlapping each other to form flower petal like shape . Using a cardboard cut to profile , adjust each petal by gluing to the precedent at mid point where an external circular cardboard fixes the mouth . Apply 1ohm resistor in series and a capacitor to reject low frequencies , apply a pink noise . The noise starts with the consonant F and follows with a vowel . If you hear Fe as feather your flare is opening too fast . If you hear Fo as fault , it is too slow . the right sound you must have is fa as father . On measurement you will just see the low spectrum increase or decrease slightly . Try out with synthesized piano notes to verify the standing waves at each note. The 1 ohm is to eliminate the standing wave that occurs at 2Fc on exponential horns . If you change the driver you will here a different vowel . Don't rush , some kind of equalization occurs in your ears , and the percieved spectrum differs by time . Listen the music several days before you decide . Finally , measure the -6db level diffusion angle at cutoff frequancy and determine by Don Keele's equation the active diameter to trim off the unnecessary .

To built horns I use fiber glass strips , dismantled from 600gr/m² roving to wind upon a plaster model . The winding direction is reversed at each layer . While the precedent is still wet I start winding the second pair to squeeze off the exceeding resin . 3 pair layers form at the throat (tight winding) 2mm thick . Once cured , by tapping with the edge of a knife , the horn sounds glassware . At the end , the external is painted by elastomer (uses to waterproof decks) and it sounds totally inert .

page86 . He traced several flares all of same Fc . You notice that all these curves follow the initial about 450mm the same exponential flare. The diameter at this point is about 5 times the throat , more exactly 4.81 times where the exponential reaches it's Fc quarter wavelength . So , whatever is your choise you have to built first this exponential quarter wavelength . Once built and the driver installed , glue with hot gun trapizoidal shape long pieces of cardboard 2mm on the mouth overlapping each other to form flower petal like shape . Using a cardboard cut to profile , adjust each petal by gluing to the precedent at mid point where an external circular cardboard fixes the mouth . Apply 1ohm resistor in series and a capacitor to reject low frequencies , apply a pink noise . The noise starts with the consonant F and follows with a vowel . If you hear Fe as feather your flare is opening too fast . If you hear Fo as fault , it is too slow . the right sound you must have is fa as father . On measurement you will just see the low spectrum increase or decrease slightly . Try out with synthesized piano notes to verify the standing waves at each note. The 1 ohm is to eliminate the standing wave that occurs at 2Fc on exponential horns . If you change the driver you will here a different vowel . Don't rush , some kind of equalization occurs in your ears , and the percieved spectrum differs by time . Listen the music several days before you decide . Finally , measure the -6db level diffusion angle at cutoff frequancy and determine by Don Keele's equation the active diameter to trim off the unnecessary .

To built horns I use fiber glass strips , dismantled from 600gr/m² roving to wind upon a plaster model . The winding direction is reversed at each layer . While the precedent is still wet I start winding the second pair to squeeze off the exceeding resin . 3 pair layers form at the throat (tight winding) 2mm thick . Once cured , by tapping with the edge of a knife , the horn sounds glassware . At the end , the external is painted by elastomer (uses to waterproof decks) and it sounds totally inert .

I found out that in Hornresp you can put the half angle for JMLC horns and you can read the angle for tractrix.

Attachments

Hi David,

Yes I found that but with Tractrix I have to lower Fc to get to the 5 degrees.

Is it a big problem if it's not exactly 5 degrees?

Rob

Yes I found that but with Tractrix I have to lower Fc to get to the 5 degrees.

Is it a big problem if it's not exactly 5 degrees?

Rob

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Design Tractrix or Le Cleach for JBL 2446