Mark, rather than other's opinions, what's yours?

Servos, can't use 'em. Ultra-matched pairs and offset trims is the only way to go.

OPA604, OPA134, and or TL051 all seem to work well in the DC servos I've built.

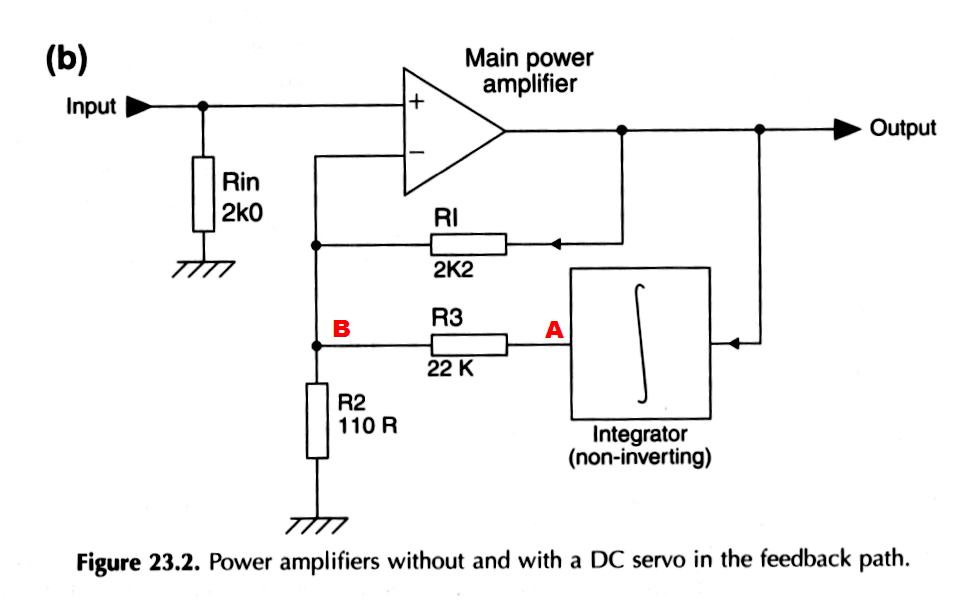

People might sometimes forget that the distortion contribution of the DC servo, is greatly attenuated by the weighted summing network R1-R2-R3.

edit- and of course if you choose an opamp "single" then the 8 pin package gives access to external trimming with a 15-turn trimpot. And now you can trim out those last two millivolts yourself, manually. If yer cheap you can buy JFET opamps with good Ibias specs but crummy Vos specs, and then trim it out.

_

People might sometimes forget that the distortion contribution of the DC servo, is greatly attenuated by the weighted summing network R1-R2-R3.

edit- and of course if you choose an opamp "single" then the 8 pin package gives access to external trimming with a 15-turn trimpot. And now you can trim out those last two millivolts yourself, manually. If yer cheap you can buy JFET opamps with good Ibias specs but crummy Vos specs, and then trim it out.

_

Last edited:

Servos, can't use 'em. Ultra-matched pairs and offset trims is the only way to go.

I use a chopper stabilized circuit with flat gain to DC. It seems to be less sensitive to acoustic feedback for some reason.

Most amps have (very) high loop gains at LF.

You don’t need high loop gains on the servo to reduce the output DC off set to manageable levels ( say +- 5 or 10 mV).

If you are designing ZGFB or low loop gain amplifiers then dial the offset out with a pot and be done with it. The sx- Amp has 34 dB loop gain at DC . At switch on the offset is c 40-50 mV and a minute later it’s about 5 mV.

You don’t need high loop gains on the servo to reduce the output DC off set to manageable levels ( say +- 5 or 10 mV).

If you are designing ZGFB or low loop gain amplifiers then dial the offset out with a pot and be done with it. The sx- Amp has 34 dB loop gain at DC . At switch on the offset is c 40-50 mV and a minute later it’s about 5 mV.

Servos, can't use 'em. Ultra-matched pairs and offset trims is the only way to go.

I remember that in the ‘olden days’ if you used the offset trim facility on some opamps, the drift increased.

On a narrow span SG amp it could cause issues.

If you use a servo and trim the amp output to 0 mV offset manually as well, the servo output provides a very useful DC offset error output in case of a fault. The minute you cannot control the loop, you know you have a serious issue at hand . . . Disconnect the speakers ‘chop chop’

Seems to me the first question is "What is an acceptable DC offset?" As the output of an audio power amplifier should have low enough offset not to affect the voice coil centering thus adding distortion that might be the place to start. The preamp DC offset would be a small part of that influenced of course by the gain of the amplifier.

Of course it is also possible that it is so easy to null the preamp that reaching such a number is trivial.

A method I have used in the past on audio power amplifiers is to use the DC servo to drive a resistor that heats one of the input transistors.

So the first issue becomes what DC offset matters to a loudspeaker, worst case?

Of course it is also possible that it is so easy to null the preamp that reaching such a number is trivial.

A method I have used in the past on audio power amplifiers is to use the DC servo to drive a resistor that heats one of the input transistors.

So the first issue becomes what DC offset matters to a loudspeaker, worst case?

C’mon Ed. You can get to < 10 mV with very little effort whether you servo it or dial it out. Why complicate it with a Q like that 😀

TLO71 or 72 works just fine for a power amp and they cost pennies.

This is not something you need to sweat over.

😉

I've found that just changing the power supply buffer caps for a servo op amp will change the final sonic impression, so....

sweat over? yes?

caveat: rest of amp and servo as a pair - results will vary... etc..

Seems to me the first question is "What is an acceptable DC offset?" As the output of an audio power amplifier should have low enough offset not to affect the voice coil centering thus adding distortion that might be the place to start. The preamp DC offset would be a small part of that influenced of course by the gain of the amplifier.

Of course it is also possible that it is so easy to null the preamp that reaching such a number is trivial.

A method I have used in the past on audio power amplifiers is to use the DC servo to drive a resistor that heats one of the input transistors.

So the first issue becomes what DC offset matters to a loudspeaker, worst case?

Long story short, DC offset matters to a loudspeaker driver, the cable, the crossover and so on. Mr cumulative and his always present minions will have their way.

C’mon Ed. You can get to < 10 mV with very little effort whether you servo it or dial it out. Why complicate it with a Q like that 😀

10 mV would be -72 dB re 200 watts into a loudspeaker. Although it seems high that level would be lost when including the normal accuracy in voice coil centering. (Quick calculation predicts less than .001" of offset.)

But if the DC is trimmed to get that level, does it stay stable over temperature changes?

With normal professional amplifiers often having a voltage gain of 20 (26 dB.) that would require a preamp to be 500 microvolts or less. Probably much less as the audio power amplifier will have some contribution.

So where does that leave us, trimmer or servo? Which opamp?

Perhaps true for AC, but I do not believe that any normal pro amplifier for audio will have that kind of gain at DC.... With normal professional amplifiers often having a voltage gain of 20 (26 dB.) that would require a preamp to be 500 microvolts or less. Probably much less as the audio power amplifier will have some contribution....

Isn't this a perfect opportunity for another Ed Simon battery powered foeces-rig in a small metal Bud box? Connect it to the output terminals of a pro-audio power amp, and measure the DC offset. Measure it at power up. Measure it after 1 hour of idling with no input or output signal. Measure it while playing normal pro-audio level outputs in a typical pro audio environment.

You could incorporate one or more different options for integration time, i.e., the average value of DC offset over what interval? Fun and right up your alley.

You could incorporate one or more different options for integration time, i.e., the average value of DC offset over what interval? Fun and right up your alley.

The pro guys I know also use transformers in some situations.suddenly a capacitor is starting to seem like a good solution 😛

Only to people with common sense : )suddenly a capacitor is starting to seem like a good solution 😛

An output cap for the truly enlightened ........

Mark Johnson is making sense. Most here do not really have much experience with making servos, or they have an odd opinion about them.

The IC's supporting PRACTICAL servos of audio equipment started in the late 70's, when the price of jfet input IC's went down low enough. Bipolar parts just had too many problems to work efficiently. The problem with the first jfet IC's was OFFSET. That could sometimes be nulled out, I did it with my first Vendetta Research input stage servo, but soon enough the AD412 came out that was 'laser trimmed'. A great improvement that let us omit the DC balance pot. But another potential problem with servos is added NOISE, this can be important in very quiet circuits, and I upgraded to the AD712 that was not entirely quiet, but at least this was a consistent part in that regard. Used them for years. Of course, sometimes, you really need a REALLY LOW offset that is consistent. Then CHOPPER IC's can be useful. My first effort (need) was in 1983 to be able to direct couple the record amp head without a huge quality cap, in Dave Wilson's 30ips analog recorder. It seems to work, even today. Probably, noise considerations could intrude, but not in this case. I am suspicious of chopper ics in for this in general, however. Today, I usually depend on the OPA 2134, that has better DC offset than the AD712 did, and it seems to do the job, cheaply and effectively.

Now, servos can be a problem, if they are too tight, and work along with the music. It is best to get them to work down low at frequencies below 1Hz for the most part, and act as a DC MONITOR, rather than as a more active controller. Linearity could be important, but like Mark noted, much of the potential distortion contribution can be greatly attenuated through careful selection of the resistors in the the servo. You must disconnect the servo from the music, if at all practical.

Some like PMA may have found another solution, but all other solutions have their own problems. The biggest problem of trying to direct couple amps or preamps is temperature drift. This can be a real engineering challenge, perhaps too much of a challenge. It is usually better to make a better servo, and to figure out what you did in the past with servos that caused concern about using them.

The IC's supporting PRACTICAL servos of audio equipment started in the late 70's, when the price of jfet input IC's went down low enough. Bipolar parts just had too many problems to work efficiently. The problem with the first jfet IC's was OFFSET. That could sometimes be nulled out, I did it with my first Vendetta Research input stage servo, but soon enough the AD412 came out that was 'laser trimmed'. A great improvement that let us omit the DC balance pot. But another potential problem with servos is added NOISE, this can be important in very quiet circuits, and I upgraded to the AD712 that was not entirely quiet, but at least this was a consistent part in that regard. Used them for years. Of course, sometimes, you really need a REALLY LOW offset that is consistent. Then CHOPPER IC's can be useful. My first effort (need) was in 1983 to be able to direct couple the record amp head without a huge quality cap, in Dave Wilson's 30ips analog recorder. It seems to work, even today. Probably, noise considerations could intrude, but not in this case. I am suspicious of chopper ics in for this in general, however. Today, I usually depend on the OPA 2134, that has better DC offset than the AD712 did, and it seems to do the job, cheaply and effectively.

Now, servos can be a problem, if they are too tight, and work along with the music. It is best to get them to work down low at frequencies below 1Hz for the most part, and act as a DC MONITOR, rather than as a more active controller. Linearity could be important, but like Mark noted, much of the potential distortion contribution can be greatly attenuated through careful selection of the resistors in the the servo. You must disconnect the servo from the music, if at all practical.

Some like PMA may have found another solution, but all other solutions have their own problems. The biggest problem of trying to direct couple amps or preamps is temperature drift. This can be a real engineering challenge, perhaps too much of a challenge. It is usually better to make a better servo, and to figure out what you did in the past with servos that caused concern about using them.

Last edited:

I've found that just changing the power supply buffer caps for a servo op amp will change the final sonic impression, so....

sweat over? yes?

caveat: rest of amp and servo as a pair - results will vary... etc..

You have other issues then. But lets not argue too much on that point.

I can dial the offset on my power amps between +-20 mV and still get < 10ppm at 1kHz 200W into 8 Ohms.

Measurements count.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III