Hey all,

I've been looking into building myself a pair of speakers for a while, and possibly building a pair for my family as a gift. I'm eyeing a pair of bookshelf speakers I can put fairly close to a wall in a small room; I've found a couple designs that would work perfectly for me. Paul Carmody's Speedster looks amazing, and at a lower price point Ben Shaffer's Stance is pretty cool.

However, I'm the lead instructor for the Shopbot CNC Router at my university, and I just got a bunch of really nice 3/4" baltic birch for free. So, my question to you all- What's the craziest cabinet design you can think of? General parameters are still the same- Speakers are for a small room, and my budget for drivers/crossovers is around $200-$250. Otherwise, nothing is out of question- I can cut nearly anything with our CNC router, and have a ton of material. What should I make?

I've been looking into building myself a pair of speakers for a while, and possibly building a pair for my family as a gift. I'm eyeing a pair of bookshelf speakers I can put fairly close to a wall in a small room; I've found a couple designs that would work perfectly for me. Paul Carmody's Speedster looks amazing, and at a lower price point Ben Shaffer's Stance is pretty cool.

However, I'm the lead instructor for the Shopbot CNC Router at my university, and I just got a bunch of really nice 3/4" baltic birch for free. So, my question to you all- What's the craziest cabinet design you can think of? General parameters are still the same- Speakers are for a small room, and my budget for drivers/crossovers is around $200-$250. Otherwise, nothing is out of question- I can cut nearly anything with our CNC router, and have a ton of material. What should I make?

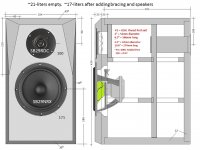

There are a number of designs out there using a stacking technique to get curved boxes, some even try to get a profiled inner surface to cut down on standing waves (debatable benefit given the length ratios involved).

Question - I see lots of high quality speaker cabinets use "wavy" insides

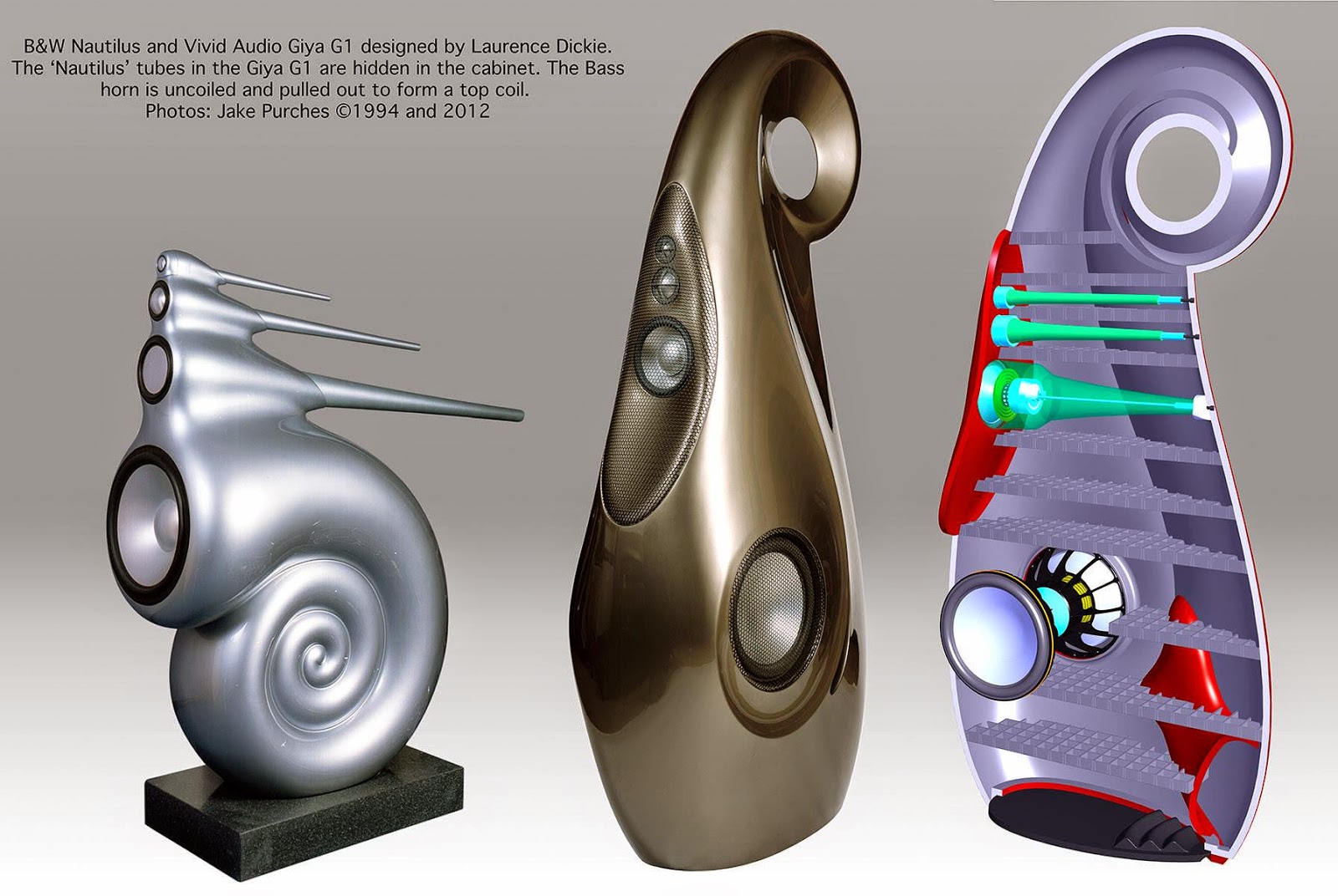

There are also nautilus shell type designs, glue a stack of ply together to give yourself a say 5” stack the mill out a nautilus shape for a full range driver e.g. alpair 10ms. Then repeat, stick together and fill to taste.

LoudSnail – Milling of the woofer enclosure parts finished | Crazy Audio

There are also a few transmission line and horn speakers made from stacked ply.

stacked mdf speaker box

However, worth selecting drivers and calculating box sizes and crossover sim before designing the actual shape of the box as this will give you a starting point.

Just a couple of ideas.

Question - I see lots of high quality speaker cabinets use "wavy" insides

There are also nautilus shell type designs, glue a stack of ply together to give yourself a say 5” stack the mill out a nautilus shape for a full range driver e.g. alpair 10ms. Then repeat, stick together and fill to taste.

LoudSnail – Milling of the woofer enclosure parts finished | Crazy Audio

There are also a few transmission line and horn speakers made from stacked ply.

stacked mdf speaker box

However, worth selecting drivers and calculating box sizes and crossover sim before designing the actual shape of the box as this will give you a starting point.

Just a couple of ideas.

Last edited:

However, I'm the lead instructor for the Shopbot CNC Router at my university, and I just got a bunch of really nice 3/4" baltic birch for free. So, my question to you all- What's the craziest cabinet design you can think of? General parameters are still the same- Speakers are for a small room, and my budget for drivers/crossovers is around $200-$250. Otherwise, nothing is out of question- I can cut nearly anything with our CNC router, and have a ton of material. What should I make?

If the speakers are to be placed against a wall and to have a complex cabinet then something like a modern version of the Daline speaker might be an interesting option. That is, a wide shallow 2 way speaker using a 1" tweeter with a 5" or 6.5" midwoofer loaded by a chamber plus a long folded line. This is a picture of a variation but a brief google didn't find a link to the wireless world articles which I downloaded off the internet and possess somewhere. The downside (or upside depending on how you look at it) is that the speaker would need to be designed and I am not sure how well existing software would handle the chamber + line. Anyone?

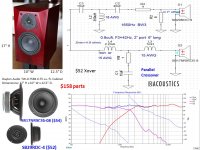

You could build a modest complexity cabinet design like Troels Illuminator with SB_Acoustics drivers. The 6.5" midwoofer will deliver -F3 = 40Hz plus room gain.

LATER.... you could work with your class to design a high value, high complexity, Artistic TransLam cabinet.

TransLam construction can provide several benefits -

=reduced edge diffraction

=functional internal bracing

=constructing a tapered volume behind the speaker to reduce resonances

=integrated waveguide

=ARTISTIC

LATER.... you could work with your class to design a high value, high complexity, Artistic TransLam cabinet.

TransLam construction can provide several benefits -

=reduced edge diffraction

=functional internal bracing

=constructing a tapered volume behind the speaker to reduce resonances

=integrated waveguide

=ARTISTIC

Attachments

Easy enough to get a CNC to he’s through a huge amount of time and material cutting out parts for any of the very interesting designs seen here or elsewhere. A bit more of a challenge to actually build them, and get none of the trans-lam joints to crack - often well after you’ve applied a finish to them. I think there are forum member here who could speak to that.

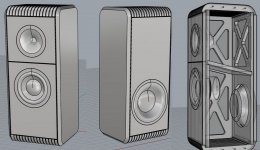

I just retired from a commercial millwork shop in which I was blessed to have access to a large format flatbed 3 axis CNC machine. Makes enclosures like the Frugelhorn, or even a matrix interlocking internal skeleton such as seen in the B&W N800 series a piece of cake - once the drawings are done.

I just retired from a commercial millwork shop in which I was blessed to have access to a large format flatbed 3 axis CNC machine. Makes enclosures like the Frugelhorn, or even a matrix interlocking internal skeleton such as seen in the B&W N800 series a piece of cake - once the drawings are done.

Front loaded horns with some curvature along the length and bracing can look impressive, even though functionally they just are front loaded horns.

To the OP, let me know if you need any help and choose the Stance kit. Being I still have them, I can tell you anything you want to know.

That said- these are meant as a free-stander with full comp BSC, but they don't sound awfully heavy bassed about a foot from a wall. The sides are double 3/4" (1.5" thick) MDF, back is 1.25" MDF, baffles are 3/4" particle board plus Formica. Ports are dual-flared and internally brace the top panel to the 1" dowel across the sides.

I even went so far as to mass-load the sides with a channel network filled with kitty litter. Another builder used ceramic tiles for mass.

Here's the original build thread...

I theorize: 'Stance' a mini 2-way with RS125-4 and Beston RT003C... -

Techtalk Speaker Building, Audio, Video Discussion Forum

Later,

Wolf

That said- these are meant as a free-stander with full comp BSC, but they don't sound awfully heavy bassed about a foot from a wall. The sides are double 3/4" (1.5" thick) MDF, back is 1.25" MDF, baffles are 3/4" particle board plus Formica. Ports are dual-flared and internally brace the top panel to the 1" dowel across the sides.

I even went so far as to mass-load the sides with a channel network filled with kitty litter. Another builder used ceramic tiles for mass.

Here's the original build thread...

I theorize: 'Stance' a mini 2-way with RS125-4 and Beston RT003C... -

Techtalk Speaker Building, Audio, Video Discussion Forum

Later,

Wolf

My version of Jon Marsh's Minerva monitors used quite a lot of CNC techniques...

Full photo album is here for possible inspiration on some aspects.

Not the most complex one can take this for sure, but this one is still looking as good 1,5 years later as it did when I finished it... My first attempt at stacked set of MDF layers 10 years ago did not share the same good faith.

Full photo album is here for possible inspiration on some aspects.

Not the most complex one can take this for sure, but this one is still looking as good 1,5 years later as it did when I finished it... My first attempt at stacked set of MDF layers 10 years ago did not share the same good faith.

Attachments

Hey all,

...However, I'm the lead instructor for the Shopbot CNC Router at my university, and I just got a bunch of really nice 3/4" baltic birch for free. So, my question to you all- What's the craziest cabinet design you can think of? ... What should I make?

I would suggest a reasonably complex construction for it would have served your purpose better. A hexagram as a construction building block is what I would have chosen if it were me. May be a hexagram matrix could be designed elegantly.

Paul Carmody's Speedster looks amazing (snip)

Have you seen the Speedster 'Limo' TMM floorstander? It may be a better way to cut up a lot of plywood than a smaller bookshelf speaker?

Here's a Magico as a reference point for non-complex.

Attachments

Thanks all for the wide variety of options! There are some really beautiful designs out there, and some real strange ones.

Translam certainly looks interesting- Unfortunately I don't have enough ply to do a larger design, but maybe a set of bookshelves with some nice curves?

The two options that really jump out at me at the moment are the hypercube speakers and the cornu spiral horn.

As for the hypercube speakers, Rhombic Dodecahedrons are almost trivial to do with the CNC router and a 60degree bit, and I actually just build a variable bevel angle crosscut sled for our bandsaw, so the square truncation shouldn't be difficult either. I have a crappy pair of drivers laying around and I might throw together a prototype in the next few days if I can find the time. As for decent drivers, I imagine something like a 4" midrange? I have an active subwoofer for bass so I don't need to go too low. Maybe I should try the hyperFAST design?

I also like the look of the the cornu spirals- wall placement is a plus, they also seem to be perfect for my listening room. Coincidentally, they also seem to use 4" midrange drivers- perhaps I could build both designs and decide which works better?

Translam certainly looks interesting- Unfortunately I don't have enough ply to do a larger design, but maybe a set of bookshelves with some nice curves?

The two options that really jump out at me at the moment are the hypercube speakers and the cornu spiral horn.

As for the hypercube speakers, Rhombic Dodecahedrons are almost trivial to do with the CNC router and a 60degree bit, and I actually just build a variable bevel angle crosscut sled for our bandsaw, so the square truncation shouldn't be difficult either. I have a crappy pair of drivers laying around and I might throw together a prototype in the next few days if I can find the time. As for decent drivers, I imagine something like a 4" midrange? I have an active subwoofer for bass so I don't need to go too low. Maybe I should try the hyperFAST design?

I also like the look of the the cornu spirals- wall placement is a plus, they also seem to be perfect for my listening room. Coincidentally, they also seem to use 4" midrange drivers- perhaps I could build both designs and decide which works better?

Having had a ponder on how to develop my earlier daline suggestion and combine it with a scheduled build it occurred to me that this is both a fun spec for a project and an appropriate one for speaker DIY over the winter (i.e. lots of inside design in the warm). Although often used for mainly ornamental reasons layers of glued wood can also be used to create complex smoothly curving and twisting passageways for more functional reasons. Simulating the acoustics will of course also be a fun part of the challenge.What's the craziest cabinet design you can think of? Speakers are for a small room, and my budget for drivers/crossovers is around $200-$250. I can cut nearly anything with our CNC router.

Not sure the timescale will fit the OP's but is this sort of thing of interest for others?

Piano low A = 27.8HzThe 6.5" midwoofer will deliver -F3 = 40Hz plus room gain.

Bass E-string = 40Hz

Christmas is coming! Ask Santa to bring you some BASS.

Tom E

Beautiful, Voluptuous cabinet.

Do you still have finger prints after all the sanding?

What drivers and crossover slopes did you use?

Ikeda wooden bowls have been used to get low diffraction "music of the spheres".

Beautiful, Voluptuous cabinet.

Do you still have finger prints after all the sanding?

What drivers and crossover slopes did you use?

Ikeda wooden bowls have been used to get low diffraction "music of the spheres".

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Stupidly Complex Cabinets