Hi! It's my first post on this forum and I would like to start a thread where I'll tell you my story of building full size planar magnetic headphones.

Hope DiyAudio community will be interested also I hope to hear some advices.

Fankly speaking, I'm rather new in Head-Fi (but not new in Hi-Fi and DIY 😉 ) and I hope to hear your opinion (and maybe some tips!) about my work. I've started building headphones exactly 1 year ago and now I think I have something interesting to tell to the world.

What are my goals?

1. To build a full size open planar magnetic headphones

2. Achieve a sound of a really high level ( my landmarks are Audeze LCD-3 and Hifiman He-1000)

3. Headphones should be ready at least for a small series

4. Net cost 100-150$

So the story begins...

My first step was to make a simple planar magnetic transducer. From my point of view starting from the beginning with building a headphone is a really bad idea. I'm not novice in making non-dynamic transducer: i've already built electrostatic and plasma speakers, so making an isodynamic speaker wasn't a difficult task for me. I went to market, bought same magnets, opened Corel Draw, made simple drawings and cut with laser a few plastic and metal parts.

Next day I received such result :

My test planar speaker

And same speaker with one sided magnet system:

Same speaker with one sided magnet system

If Admin will consider my post worthy and let me start the thread I'll continue to explain how to make planar headphones in details.

Hope DiyAudio community will be interested also I hope to hear some advices.

Fankly speaking, I'm rather new in Head-Fi (but not new in Hi-Fi and DIY 😉 ) and I hope to hear your opinion (and maybe some tips!) about my work. I've started building headphones exactly 1 year ago and now I think I have something interesting to tell to the world.

What are my goals?

1. To build a full size open planar magnetic headphones

2. Achieve a sound of a really high level ( my landmarks are Audeze LCD-3 and Hifiman He-1000)

3. Headphones should be ready at least for a small series

4. Net cost 100-150$

So the story begins...

My first step was to make a simple planar magnetic transducer. From my point of view starting from the beginning with building a headphone is a really bad idea. I'm not novice in making non-dynamic transducer: i've already built electrostatic and plasma speakers, so making an isodynamic speaker wasn't a difficult task for me. I went to market, bought same magnets, opened Corel Draw, made simple drawings and cut with laser a few plastic and metal parts.

Next day I received such result :

My test planar speaker

And same speaker with one sided magnet system:

Same speaker with one sided magnet system

If Admin will consider my post worthy and let me start the thread I'll continue to explain how to make planar headphones in details.

Bring it on! Definitely on my bucket list. I have been eyeing a thread on head-fi for diy electrostatic headphones - looks like something I will be able to do.

I've started from small planar transduces just to understand how everything works.

Step 1:

Tracing diaphragm

Please look, current in all 4 groups of traces flow in the same direction.

Step 2 - placing magnets between group of traces. How I made it I've shown on picture.

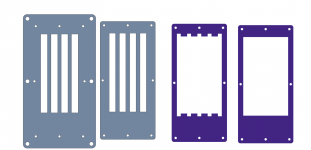

Step 3 - making a housing. That's the most simple. Just draw anything you want in any vector editor and cut it with laser.

Gray details are from steel, purple are from plastic.

If somebody is interested I'll explain how to make a membrane with conductor lines, what material should be used and how to assemble this.

Step 1:

Tracing diaphragm

Please look, current in all 4 groups of traces flow in the same direction.

Step 2 - placing magnets between group of traces. How I made it I've shown on picture.

Step 3 - making a housing. That's the most simple. Just draw anything you want in any vector editor and cut it with laser.

Gray details are from steel, purple are from plastic.

If somebody is interested I'll explain how to make a membrane with conductor lines, what material should be used and how to assemble this.

Attachments

After I realized how to planar magnetic speaker works I've decided to build first headphones. As a material for membrane I use Dupont Pyralux. It's some sort of kapton + copper. I've achieved 0.15 mm width of trace.

Here photos of my first headphone prototype. I cutted with laser 2 mm plastic spacers and 0.5 mm steel frame.

Impedance of this sample spiral is ~25 ohm.

Here photos of my first headphone prototype. I cutted with laser 2 mm plastic spacers and 0.5 mm steel frame.

Impedance of this sample spiral is ~25 ohm.

Attachments

-

900x900px-LL-4dc76449_post_2532_1460129528_e6003d1341152a2443275c24b31ca771.jpeg68.4 KB · Views: 618

900x900px-LL-4dc76449_post_2532_1460129528_e6003d1341152a2443275c24b31ca771.jpeg68.4 KB · Views: 618 -

900x900px-LL-6ff3b22f_post_2532_1460659714_5a29a982aa3cdd5b7523678eb25b12fa.jpeg85.7 KB · Views: 572

900x900px-LL-6ff3b22f_post_2532_1460659714_5a29a982aa3cdd5b7523678eb25b12fa.jpeg85.7 KB · Views: 572 -

900x900px-LL-72e9f034_post_2532_1460819732_7ea2fc0895ec7e44ea4cd5eab1550849.jpeg45.3 KB · Views: 601

900x900px-LL-72e9f034_post_2532_1460819732_7ea2fc0895ec7e44ea4cd5eab1550849.jpeg45.3 KB · Views: 601 -

900x900px-LL-8f03d30e_post_2532_1460659804_208ed610d371dd5deb921ed371839a36.jpeg75.6 KB · Views: 301

900x900px-LL-8f03d30e_post_2532_1460659804_208ed610d371dd5deb921ed371839a36.jpeg75.6 KB · Views: 301 -

900x900px-LL-a24b467b_post_2532_1460659759_6a74413fd5e41c3a95048fc93b106264.jpeg85.6 KB · Views: 384

900x900px-LL-a24b467b_post_2532_1460659759_6a74413fd5e41c3a95048fc93b106264.jpeg85.6 KB · Views: 384

We etch copper plated PCBs with HCl (muriatic acid) and H2O2 (hydrogen peroxide) all the time. Probably usual photo resist methods for laying traces prior to etch?

Very interesting thread.

Very interesting thread.

We etch copper plated PCBs with HCl (muriatic acid) and H2O2 (hydrogen peroxide) all the time. Probably usual photo resist methods for laying traces prior to etch?

Yep, photo resist. But to achieve 0.15 mm width of trace I need to do this on factory. It's not smth you can make in your kitchen. 😀

Very interesting thread.

Thanks!

Since you got everybody hyped up you cannot go to bed now!

I can't show almost 1 year progress in 1 post 😛

We etch copper plated PCBs with HCl (muriatic acid) and H2O2 (hydrogen peroxide) all the time.

I prefer FeCl3 (ferric chloride).

Last edited:

I can buy 1 gallon (3.9L) of HCl for $8. 12 oz Bottles of hydrogen peroxide from drugstore are $1 ea. It's all ok to flush down drain once neutralized with soda.

Hello, i construct for many years (as a hobby) with succsess electrostatic headphones and now i want to begin with planar headphones. Please let me know the required dimensions of magnets, because i found in Amazon.de only 35x4x2mm neodmium magnets (https://www.amazon.de/-/en/gp/product/B00EE579JM/ref=ox_sc_act_title_1?smid=AMN954BUWHYCG&psc=1) and the dimensions of membrane. Also i found on ebay the piralux pcb. Please let me know the required thickness of memrbane. Also i have a big question about the membrane: In electrostatic headphones we use 2 or 3 micron membrane in order to achive a good frequency responce. I show in your images that the thickness of your membrane is much higher. How you achive the best frequency responce with that thickness? In electrostatic headphones we need to apply tension on membrane, in planar i suppose that you dont apply any tension.I've started from small planar transduces just to understand how everything works.

Step 1:

Tracing diaphragm

Please look, current in all 4 groups of traces flow in the same direction.

Step 2 - placing magnets between group of traces. How I made it I've shown on picture.

Step 3 - making a housing. That's the most simple. Just draw anything you want in any vector editor and cut it with laser.

Gray details are from steel, purple are from plastic.

If somebody is interested I'll explain how to make a membrane with conductor lines, what material should be used and how to assemble this.

- Home

- Amplifiers

- Headphone Systems

- Diy planar headphones in details