Hi Gang,

Years ago when I was here often and DIYing, I bought an Agilent (Keysight) U1242A DMM. It was recommended. Paid $220 from Transcat.

A year or two ago a freak thing occurred and took it down. I pulled it out and found the batteries dead. When replacing the batteries, I found they leaked. The leakage went down one of the holes where the negative prongs extended to the metal square contact of the PCB. Cleaned it up and Voila, worked fine again.

Pulled it out again yesterday and it was giving an AErr code. Called Transcat and Keysight and got nowhere except to find repair costs way more than I paid for it. If I put 10 hours on this since I bought it, it's allot!

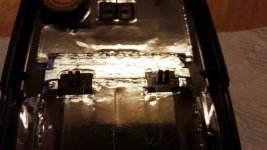

So I opened it today to find the negative contact pad on back of the PCB has gone missing. I guess I didn't clean the battery acid residue well enough and it kept eating. (see pics below)

Anybody have any creative ideas on how to repair/replace the contact pad on the back of the PCB? Buying a new DMM is out of the financial question right now!

Thank you as always!

Years ago when I was here often and DIYing, I bought an Agilent (Keysight) U1242A DMM. It was recommended. Paid $220 from Transcat.

A year or two ago a freak thing occurred and took it down. I pulled it out and found the batteries dead. When replacing the batteries, I found they leaked. The leakage went down one of the holes where the negative prongs extended to the metal square contact of the PCB. Cleaned it up and Voila, worked fine again.

Pulled it out again yesterday and it was giving an AErr code. Called Transcat and Keysight and got nowhere except to find repair costs way more than I paid for it. If I put 10 hours on this since I bought it, it's allot!

So I opened it today to find the negative contact pad on back of the PCB has gone missing. I guess I didn't clean the battery acid residue well enough and it kept eating. (see pics below)

Anybody have any creative ideas on how to repair/replace the contact pad on the back of the PCB? Buying a new DMM is out of the financial question right now!

Thank you as always!

Attachments

You could solder a fresh bit of copper over the existing pad. or cut a finger off of an old PCB edge connector to get the gold plate. The fingers on the contact should have enough flex to accommodate a little extra thickness. Make sure any remaining batery residue has been removed and clean the fingers. (I would probably make a big solder blob and leave it if it works but that's pretty crude.)

You could solder a fresh bit of copper over the existing pad. or cut a finger off of an old PCB edge connector to get the gold plate. The fingers on the contact should have enough flex to accommodate a little extra thickness. Make sure any remaining batery residue has been removed and clean the fingers. (I would probably make a big solder blob and leave it if it works but that's pretty crude.)

Thank you Demian!

If I cut off a 5/16 x 5/16" square piece of copper (or whatever the exact footprint is) off a blank PCB (double thick), clean and flux and tin both sides, and then flux the area it needs to lay on only, heat and solder quickly, do you think that will stick well enough or should I heat resistant epoxy it in and bridge the solder to the lead feeding to it on the top left?

Or is there some better way for quality and reliability?

Thanks again?

Last edited:

What about adhesive copper tape, with a wire soldered on?

Yeah, thanks!

I thought about that for a second. But the metal fork contacts coming from the back cover (and battery housing) will probably gouge right through putting me right back here. I think I need something way more stable and one with the PCB.

I am hoping some of the guys here have PCB repair experience.

The typical repair for a lifted pad would be to harvest on from another PCB and the lead would hold the pad down. In your case, if you had some of the copper foil tape it would be substantial enough. however thats expensive for 4 sq mm worth. I would lift some copper from a board like i mentioned. Its not hard with heat to get the foil to let go. (Too easy too often). Ideally some solder paste between the new pad and the old pad and hot air but heat from a soldering iron would work fine. What is the condition of the fingers that contact the pad?

Thanks! Wish me luck! I'm going to give it a whirl tomorrow! 😱

You can see the contact forks above in the third picture (click on the thumbnail for a larger view). Unaffected by the battery acid (like new). They are what brings the power from the battery compartment in the back casing to the PCB gold pads.

You can see the contact forks above in the third picture (click on the thumbnail for a larger view). Unaffected by the battery acid (like new). They are what brings the power from the battery compartment in the back casing to the PCB gold pads.

The typical repair for a lifted pad would be to harvest on from another PCB and the lead would hold the pad down. In your case, if you had some of the copper foil tape it would be substantial enough. however thats expensive for 4 sq mm worth. I would lift some copper from a board like i mentioned. Its not hard with heat to get the foil to let go. (Too easy too often). Ideally some solder paste between the new pad and the old pad and hot air but heat from a soldering iron would work fine. What is the condition of the fingers that contact the pad?

If its power the contacts are less critical. There is enough current for it to be less sensitive to contact quality.

FOOD for THOUGHT:Remember to clean and wash down with baking soda any battery leaks or you will be repairing it again. Same with leaking capacitors. Acid under soldermask (Black copper). I just helped a user repair a AP System One that he spent several hours chasing the problem.

Good hunting. Duke🙂

Good hunting. Duke🙂

- Status

- Not open for further replies.

- Home

- Design & Build

- Equipment & Tools

- Creative Agilent U1242A repair help needed!