Actually it is measurable.

Please provide a coherent technical explanation, if possible with reliable references. Otherwise, the above is just a bluff.

We are talking about whole house gfi , not individual outlet. I doubt these have been required for a long time. And these are the only ones that would stop the ground rod leakage Ive been talking about. I'm not rewriting past posts. No one has proved my point wrong, and those that have tried are confused about my point.

My last post on the subject. From Wikipedia

Separating low signal ground from a noisy ground

In television stations, recording studios, and other installations where signal quality is critical, a special signal ground known as a "technical ground" (or "technical earth", "special earth", and "audio earth") is often installed, to prevent ground loops. This is basically the same thing as an AC power ground, but no general appliance ground wires are allowed any connection to it, as they may carry electrical interference. For example only audio equipment is connected to the technical ground in a recording studio.[8] In most cases, the studio's metal equipment racks are all joined together with heavy copper cables (or flattened copper tubing or busbars) and similar connections are made to the technical ground. Great care is taken that no general chassis grounded appliances are placed on the racks, as a single AC ground connection to the technical ground will destroy its effectiveness. For particularly demanding applications, the main technical ground may consist of a heavy copper pipe, if necessary fitted by drilling through several concrete floors, such that all technical grounds may be connected by the shortest possible path to a grounding rod in the basement.

Thanks for making your final post something that that in the end, stipulates that all of the grounds are firmly connected to the same place, and as such they are basically return points.

No way can a high end grounding box that is not also connected to a ground return fulfill the requirements stated above.

It can turn out to be a clear case of re-inventing the wheel. Not that doing such things is always bad, but then it is just a training exercise. If you've already done the training exercise several times, well then that may raise some questions about your trainability.

If you don't learn something new each time you do a new design/build/debug/measure, then either you're doing it wrong or you're incapable of learning.

If diy is such a pointless thing to you, don't do it. There's lots of non-diy forums for you to haunt.

Wikipedia, quoted by cbdb:

wikipedia said:\

Separating low signal ground from a noisy ground

In television stations, recording studios, and other installations where signal quality is critical, a special signal ground known as a "technical ground" (or "technical earth", "special earth", and "audio earth") is often installed, to prevent ground loops. This is basically the same thing as an AC power ground, but no general appliance ground wires are allowed any connection to it, as they may carry electrical interference. For example only audio equipment is connected to the technical ground in a recording studio.[8] In most cases, the studio's metal equipment racks are all joined together with heavy copper cables (or flattened copper tubing or busbars) and similar connections are made to the technical ground. Great care is taken that no general chassis grounded appliances are placed on the racks, as a single AC ground connection to the technical ground will destroy its effectiveness. For particularly demanding applications, the main technical ground may consist of a heavy copper pipe, if necessary fitted by drilling through several concrete floors, such that all technical grounds may be connected by the shortest possible path to a grounding rod in the basement.

It seems to me that this neatly illustrates a serious confusion between signal ground and safety ground, and may exhibit the false idea of ground as a 'sink' for anything unwanted in a system. Have I misunderstood it? The fact that it may be common practice is not evidence that it is correct.

What confusion?

A technical ground accepts and addresses the fact that an electrical appliance such as an arc welder, large motor with a sparking commutator, or other such thing can couple a lot of EMI into its safety ground. If the safety ground cabling has significant series impedance going back to its reference point, then it can have a noise signal imposed on it. Hook that noisy safety ground up to certain sensitive or poorly designed equipment, and the imposed noise can reduce the noise performance of that equipment.

A technical ground should provide not only the usual ground return path, but also be relatively free of noise. One way to obtain that freedom from noise is simply not hooking anything to it that would couple excessive noise into it.

If you don't learn something new each time you do a new design/build/debug/measure, then either you're doing it wrong or you're incapable of learning.

Of course.

But, if you have to learn the same lesson over and over again, maybe its time to consider some possible problems with your self-education program.

How many times does one have to repeat the same simple mistakes to please some people around here? Apparently lots.

If diy is such a pointless thing to you, don't do it. There's lots of non-diy forums for you to haunt.

Sy, I don't agree with your apparent claim that DIY is inherently pointless and stupid.

I think that it's an opportunity to learn, and benefit from that learning. One common benefit of learning is that certain kinds of mistakes are avoided. Doesn't mean you stop making mistakes, it just means that your mistakes are more sophisticated.

Fact is that my last formal education was received in 1973. It is also true that my career path has involved significant deviations from the technical areas in which I received any formal training, followed by me returning to my roots. Repeat.

If it wasn't for DIY that circuitous path would have been far more difficult during the return phases. I kept up with the technologies I loved when I was otherwise absent from them using DIY projects as platforms for experimentation.

Sy, I don't agree with your apparent claim that DIY is inherently pointless and stupid.

I hope not, because I said no such thing. Try arguing with the points I made, not stuff you make up and attribute to me.

I hope not, because I said no such thing. Try arguing with the points I made, not stuff you make up and attribute to me.

I never said that either, but you clearly and gratuitously made it an issue in our discussion, so back at you Sy. Ever hear of the Golden Rule? ;-)

I never said that either

Sy, I don't agree with your apparent claim that DIY is inherently pointless and stupid.

Get your story straight. And stop dishonestly attributing things to me I never said. There's a word for that.

What confusion?

Wiki suggests technical ground has it's own earth spike. This is not how anyone trying to meet the wiring regs in their particular country would do it and about 40 years behind current EMC theory and practice.

Note they say ' a grounding rod' not 'The grounding rod'. If you add an extra ground rod it must be coupled to the other rod(s) already there.

Get your story straight. And stop dishonestly attributing things to me I never said. There's a word for that.

What did you call it when you did it to me?

You quite clearly said that there was a possibility that I thought DIY is pointless, and that is utterly false.

Last edited:

Wiki suggests technical ground has it's own earth spike.

Knowing that there are several Wiki articles that mention grounding,

you're obviously sending me on a wild goose chase, a game I decline to play.

This is not how anyone trying to meet the wiring regs in their particular country would do it and about 40 years behind current EMC theory and practice.

As I alluded out in a previous post, code in the US for garages that have their own breaker box is that they must also have their own ground rod(s). I put mine under the drain end of a roof gutter.

What I did not add is that the garage breaker box must be wired to the main premises breaker box, both neutral and safety ground. Obviously one or both of the hot wires as well, but that is not really relevant to this discussion about grounding.

Therefore, the additional ground rod(s) is kind of a belt-and-suspenders thing. I believe that you can add as many of them to your electrical wiring as you wish, as long as there are enough to meet code and there is code compliant wiring for both neutral and safety ground.

Additional breaker boxes in the living area need not have their own ground rods.

Knowing that there are several Wiki articles that mention grounding,

you're obviously sending me on a wild goose chase, a game I decline to play.

.

Look at your post #8664, which contains the quote which I copied. Just using the words in your own post. No wild goose chase, context there. No game, except in your mind.

Look at your post #8664, which contains the quote which I copied.

What post of yours has a copy of it?

Just using the words in your own post. No wild goose chase, context there. No game, except in your mind.

Here's the quote from wikipedia in that post:

Separating low signal ground from a noisy ground

In television stations, recording studios, and other installations where signal quality is critical, a special signal ground known as a "technical ground" (or "technical earth", "special earth", and "audio earth") is often installed, to prevent ground loops. This is basically the same thing as an AC power ground, but no general appliance ground wires are allowed any connection to it, as they may carry electrical interference. For example only audio equipment is connected to the technical ground in a recording studio.[8] In most cases, the studio's metal equipment racks are all joined together with heavy copper cables (or flattened copper tubing or busbars) and similar connections are made to the technical ground. Great care is taken that no general chassis grounded appliances are placed on the racks, as a single AC ground connection to the technical ground will destroy its effectiveness. For particularly demanding applications, the main technical ground may consist of a heavy copper pipe, if necessary fitted by drilling through several concrete floors, such that all technical grounds may be connected by the shortest possible path to a grounding rod in the basement.

There is a mention of a grounding rod, but I see no statement that it is separate.

The most important thing about the technical ground is that it is kept as separate as possible from noisy sources as possible, consistent with the rest of the spirit and letter of Electrical Code.

There is a mention of a grounding rod, but I see no statement that it is separate.

Hence why I said 'A ground rod' rather than 'the'. It infers >1 when you use the indefinite article.

According to all standardized codes there is no such thing as technical ground. It only exists in the mind of audiophiles and studio types who want to do dangerous wiring experiments rather than fix their equipment.The most important thing about the technical ground is that it is kept as separate as possible from noisy sources as possible, consistent with the rest of the spirit and letter of Electrical Code.

Please provide a coherent technical explanation, if possible with reliable references. Otherwise, the above is just a bluff.

Back EMF is well known. Should be easy to find with Google.

So a "technical/special/audio ground/earth" is simply a second safety ground to separate equipment which can receive signals from its safety ground connection from equipment which can inject signals into its safety ground connection? Are two separate grounds legal?arnyk said:A technical ground should provide not only the usual ground return path, but also be relatively free of noise. One way to obtain that freedom from noise is simply not hooking anything to it that would couple excessive noise into it.

If equipment is surrounded by an equipotential surface (or a good approximation to that) what does it matter what potential exists between that surface and a particular place in the dirt outside the building?

In the US there are GFCI receptacles and GFCI circuit breakers. There are no whole home GFCI's. A GFCI is very sensitive too small amounts of leakage currents.We are talking about whole house gfi , not individual outlet. I doubt these have been required for a long time.

A GFCI does not ask where the leakage current is going. It only checks to see if the Hot & Neutral currents are equal. Neither the Safety Ground nor the stake in the garden have anything to do with GFCI operation. In fact they are not required for GFCI operation.And these are the only ones that would stop the ground rod leakage Ive been talking about.

It's not us who needs to present proof.I'm not rewriting past posts. No one has proved my point wrong, and those that have tried are confused about my point.

It's a good thing that broadcast engineers don't learn their science from Wikipedia!..................................

My last post on the subject. From Wikipedia

Separating low signal ground from a noisy ground

In television stations, recording studios, and other installations where signal quality is critical, a special signal ground known as a "technical ground" (or "technical earth", "special earth", and "audio earth") is often installed, to prevent ground loops...........................

Ever been in a broadcast transmitter building when the tower got hit by lightning?

I have many times and because the equipment and tower were correctly installed, everything kept on working.

If you want to learn more about system installations the Ralph Morrison books are a good place to start. And they are available used for $10 or $15.

Last edited:

No, you have not misunderstood it, you are spot on..Wikipedia, quoted by cbdb:

It seems to me that this neatly illustrates a serious confusion between signal ground and safety ground, and may exhibit the false idea of ground as a 'sink' for anything unwanted in a system. Have I misunderstood it? The fact that it may be common practice is not evidence that it is correct.

(from NEC 2008)

NEC article 250.4 (A)(1) Electrical systems that are grounded shall be connected to earth in a manner that will limit the voltage imposed by lightning, line surges, or unintentional contact with higher voltage lines and that will stabilize the voltage to earth during normal operation.

and

NEC article 250.4 (A)(3) Normally non current carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected together and to the electrical supply source in a manner that establishes an effective grounding fault current path.

As pointed out in IEEE-STD-1050, code does not care at all about what the grounding or bonding does to the signal integrity. That is why there are so many issues and misunderstandings when it comes to "grounding".

That is also why any person who teaches code states right up front, LEARN the definitions of article 100. To wade into code without understanding the definitions is folly.

As an addendum, it should be added...don't get your definitions from wiki..

John

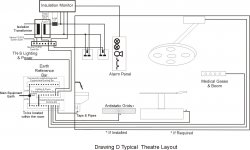

ps. Hospitals will use an isolated ground system. An isolated receptacle can be identified by the orange triangle on the front of the outlet. The outlet may also be orange color, but not required. The additional and insulated bonding conductor ties to the bonding bar upstream, and is used to prevent other equipment from contaminating the ground of sensitive equipment.

Unless of course, you are trying to prove that earthing modifies an EEG, in which case you tie the equipment, patient, kitchen sink, van de graf generator, and toro 500 weedwhacker to as many noisy electrical points as physically possible so that the EEG's are hopelessly mired in electrical noise and the researchers can claim success.. 😀

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- Funniest snake oil theories