I use REW.

I think it is relative.

Magnets "backside" is this the gap betvine the magnets?

Distortion -60db. is very good

I get-45db app in this setup.

Bernt

I think it is relative.

Magnets "backside" is this the gap betvine the magnets?

Distortion -60db. is very good

I get-45db app in this setup.

Bernt

Ok. Then you could use the RTA and the sound generator.I use REW.

I think it is relative.

Bernt

It is very good at spot distinct distortion frequencies.

I think it is relative too. So the 8 kHz peak in distortion level is about - 30 dB then.

Yes. Check what happens if you fill the gap.Magnets "backside" is this the gap betvine the magnets?

Bernt

Perhaps with tape to start with.

And, what does the B.t field look like? It might twist the pockets in the membrane at the magnets so they actually "blow" into the gap between the magnets.

Not the same configuration that you have above, but it shows what could happen:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Gap is filled with the frame:

[/IMG]

[/IMG]

[/IMG]

[/IMG]

Now i think I know your concerns

I t is the movement in the other axis due wrong field direction.

Seems that it is a small problem here.Small field strength in the other direction.

Thank you for the patience.Magnetism is difficult.

Bernt

Now i think I know your concerns

I t is the movement in the other axis due wrong field direction.

Seems that it is a small problem here.Small field strength in the other direction.

Thank you for the patience.Magnetism is difficult.

Bernt

But you must look at the B.t-plots also in the perimeter of the foil and not just in the center:

In your design, check also the tangential field at the perimeter:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

In your design, check also the tangential field at the perimeter:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Gap is filled with the frame:

Great!

Then the magnets will be like a wave guide.

This is from my latest magnet system with 7,5mm thick membrane. Measured at 15cm distance.

Resonance freQ. 350 Hz.

Now i will try to make a optimal horn.(waveguide)

What is a Q and D horn?

Horn (waveguide) begins with 32mm x150mm, and 50degrees angle, 30mm long.

Bernt

Quick answer: Q&D is Quick and Dirty.

That is, something that you make with what you got at the moment and that you don´t bother how it looks.

That is, something that you make with what you got at the moment and that you don´t bother how it looks.

Last edited:

Thank you Solhaga.

I could not find it on Google.

Hawthorne has an amt with waveguide that plays down to 500 Hz.

27cm high 40cm wide,and15cm.deep.

I will try to make something like that.

Bernt

I could not find it on Google.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Hawthorne has an amt with waveguide that plays down to 500 Hz.

27cm high 40cm wide,and15cm.deep.

I will try to make something like that.

Bernt

Last edited:

Google is always your friend, provided you ask the correct question.Thank you Solhaga.

I could not find it on Google.

What cutoff frequency do you aim for?Hawthorne has an amt with waveguide that plays down to 500 Hz.

27cm high 40cm wide,and15cm.deep.

I will try to make something like that.

Bernt

So I finally reread the whole tread 🙂 so niceeee.

As for etching method bandsei, I now don't use a laser printer but a solid ink printer from Xerox , you can get a second hand for around 75 euro. It prints wax directly on the aluminum foil. First have to rough it and clean it. Then etch with the same solution you used early copper sulfate and salt. And you are done I have not yet have a failed etch with your foil as of yet. Only downside I don't think the printer can't print longer the a4 size I believe just like a laser it first creates the image on a drum, which is the size of an a4 I guess 🙁

As for etching method bandsei, I now don't use a laser printer but a solid ink printer from Xerox , you can get a second hand for around 75 euro. It prints wax directly on the aluminum foil. First have to rough it and clean it. Then etch with the same solution you used early copper sulfate and salt. And you are done I have not yet have a failed etch with your foil as of yet. Only downside I don't think the printer can't print longer the a4 size I believe just like a laser it first creates the image on a drum, which is the size of an a4 I guess 🙁

Has anyone tried RAAL 140-20D (14×2cm) against their AMTs? Opinions?

I have the Beyma TPL-150 but my ring radiator horn tweeter beats it in clarity in the top (10-18kHz) when I cross them from 4kHz and up. But it does not sound clear enough so I am considering the RAAL.

I have the Beyma TPL-150 but my ring radiator horn tweeter beats it in clarity in the top (10-18kHz) when I cross them from 4kHz and up. But it does not sound clear enough so I am considering the RAAL.

Last edited:

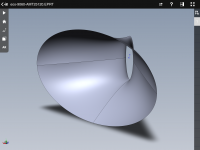

AMT AST25120 in EJMLC-1000 horn.

Nice!

You can really see the level of gain in the low end. And the horn itself does not add to much colouration to the response.

Greatly appreciated.

It does not look like it is a great driver for hornloading. The curve is already flat without a horn from 2500Hz.

I have doubts about the success in crossing below Fs, but try it and tell us! 🙂

The Beyma TPL-150 sounds pretty nasty below ~1700Hz. I like it between 2000-10000 but it is not clear enough for the highs.

The Beyma TPL-150 sounds pretty nasty below ~1700Hz. I like it between 2000-10000 but it is not clear enough for the highs.

Last edited:

I have made a horn:

[/url][/IMG]

[/url][/IMG]

[/url][/IMG]

[/url][/IMG]

Sounds ok at first.

But comparing to a "flatter " horn it sounds a bit "harsh"

I think it has to be a sort of waveguide.

I will try to find measurements too.

Bernt

Sounds ok at first.

But comparing to a "flatter " horn it sounds a bit "harsh"

I think it has to be a sort of waveguide.

I will try to find measurements too.

Bernt

Bernt I have been working with horns since 1994.

I like the concept.

Did you do any calculation?

Or just go and make seemed to be the best idea for a horn shape?

Do you have a frequency response measurement?

Just looking at the picture and having worked with planars and horns I have a guess as to what may be happening. You might have a notch or dip in the response due to the dimensions of your horn. Specifically the width. The notch may be present in the region starting around 7 kilohertz if i remember the dimensions of your horn correctly.

I like the concept.

Did you do any calculation?

Or just go and make seemed to be the best idea for a horn shape?

Do you have a frequency response measurement?

Just looking at the picture and having worked with planars and horns I have a guess as to what may be happening. You might have a notch or dip in the response due to the dimensions of your horn. Specifically the width. The notch may be present in the region starting around 7 kilohertz if i remember the dimensions of your horn correctly.

Bernt I have been working with horns since 1994.

I like the concept.

Did you do any calculation?

Or just go and make seemed to be the best idea for a horn shape?

Do you have a frequency response measurement?

Just looking at the picture and having worked with planars and horns I have a guess as to what may be happening. You might have a notch or dip in the response due to the dimensions of your horn. Specifically the width. The notch may be present in the region starting around 7 kilohertz if i remember the dimensions of your horn correctly.

That is my experience as well. While it might do wonders (gaining 5-6 dB due to the mouth's dimensions) in the low frequency region, it really screws up the response in the high frequency region, that is corresponding to the throat's dimension and curve. A carefully simulated throat is a must along of course with a really smooth design and making.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Diy AMT