Hello.

I'm thinking of making a cheap 3S2P Li-ion battery consisting of 6 of these GTL Rechargeable Battery 3.7V 5800mAh 26650 Li ion Battery ECOS #42747 -in Rechargeable Batteries from Electrical Equipment & Supplies on Aliexpress.com | Alibaba Group. Each have its own BMS (protective board against over-charging and discharging).

Now I am planning on using it in a portable speaker with two TA2024.

Anyways. I want to be able to charge these batteries as simple as possible without it being unsafe. I was thinking of making it possible to switch between the batteries connected in parallel and them connected in series. I have this ON/ON 4-way switch silver contacts high quality toggle switch ON ON 12 screws-in Toggle Switches from Electrical Equipment & Supplies on Aliexpress.com | Alibaba Group, which should suffice, from what I can tell. But I have never built anything like this before, so I have a few questions! 🙂

Oh, yeah. I am planning on charging the parallel batteries with a 4.2v smart charger.

1: Is it possible at all to charge Li-ion batteries connected in parallel? (They all have individual protective boards, so they should automatically switch off at 4.2v, right?)

2: Is a smart charger needed at all to charge Li-ion batteries, or will a constant current work, too? Staying below 0.5C charging current.

3: Will the switching solution function as wanted with the 4-way ON/ON switch?

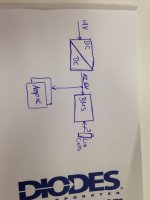

Here's a drawing of the idea:

I'm thinking of making a cheap 3S2P Li-ion battery consisting of 6 of these GTL Rechargeable Battery 3.7V 5800mAh 26650 Li ion Battery ECOS #42747 -in Rechargeable Batteries from Electrical Equipment & Supplies on Aliexpress.com | Alibaba Group. Each have its own BMS (protective board against over-charging and discharging).

Now I am planning on using it in a portable speaker with two TA2024.

Anyways. I want to be able to charge these batteries as simple as possible without it being unsafe. I was thinking of making it possible to switch between the batteries connected in parallel and them connected in series. I have this ON/ON 4-way switch silver contacts high quality toggle switch ON ON 12 screws-in Toggle Switches from Electrical Equipment & Supplies on Aliexpress.com | Alibaba Group, which should suffice, from what I can tell. But I have never built anything like this before, so I have a few questions! 🙂

Oh, yeah. I am planning on charging the parallel batteries with a 4.2v smart charger.

1: Is it possible at all to charge Li-ion batteries connected in parallel? (They all have individual protective boards, so they should automatically switch off at 4.2v, right?)

2: Is a smart charger needed at all to charge Li-ion batteries, or will a constant current work, too? Staying below 0.5C charging current.

3: Will the switching solution function as wanted with the 4-way ON/ON switch?

Here's a drawing of the idea:

An externally hosted image should be here but it was not working when we last tested it.

Just found out the batteries I picked are unprotected. I'll find some that are protected, so the same questions are still valid. 🙂

EDIT: A 4th question:

You can buy these cheap BMS-boards:

http://www.aliexpress.com/item/4A-6A-PCB-BMS-Protected-Board-for-3-Packs-18650-Li-ion-lithium-Battery/32386175340.html?spm=2114.01020208.3.2.1T238e&ws_ab_test=201407_4,201444_5,201409_3

They don't charge balanced, do they? The whole setup I was planning to make is to be able to balance the charging of each battery.

EDIT: A 4th question:

You can buy these cheap BMS-boards:

http://www.aliexpress.com/item/4A-6A-PCB-BMS-Protected-Board-for-3-Packs-18650-Li-ion-lithium-Battery/32386175340.html?spm=2114.01020208.3.2.1T238e&ws_ab_test=201407_4,201444_5,201409_3

They don't charge balanced, do they? The whole setup I was planning to make is to be able to balance the charging of each battery.

Last edited:

I'd suggest you to buy a cheap 3s charger, like the ImaxRC B3. Switching unbalanced discharged batteries from serial to parallel isn't what I'd like to do.

I'd suggest you to buy a cheap 3s charger, like the ImaxRC B3. Switching unbalanced discharged batteries from serial to parallel isn't what I'd like to do.

I can see where you're going with that, but the batteries will be discharged in series, so the capacity shouldn't vary with more than 100mah-200mah, should it?

Do you know if those cheap BMS boards I linked to in my last post have balanced charging?

Even if they not differ more than 100-200mAh, they equalize "hard" when you switch them. As Li+-Cells are very low-impedant, there's serious current flowing if not limited in some way.

3cell BMS at Aliexpress:

32252377865

3cell BMS at Aliexpress:

32252377865

Even if they not differ more than 100-200mAh, they equalize "hard" when you switch them. As Li+-Cells are very low-impedant, there's serious current flowing if not limited in some way.

3cell BMS at Aliexpress:

32252377865

Cheers! I'll go for that board and those unprotected li-ion batteries, then.

Thanks a lot for your help. 🙂

EDIT: One last question! Will I be needing a smart charger to charge a pack like that, or will a regular (constant current) 15v PSU do?

EDIT2: Nevermind. Just figured out what CC/CV means .. 🙄

EDIT3: Okay, so a CC/CV PSU is a PSU where you can regulate either voltage or current. Why exactly would that be required to charge this? Will a regular 15v switching PSU not do?

Last edited:

A 14.6V current limited supply will do. You want to limit the current to the max allowed charge current for the cells.

A 14.6V current limited supply will do. You want to limit the current to the max allowed charge current for the cells.

14.6 -(3 x 4.1V) = 2.3 V what is this , BMS protection "overhead"? does it change

Well. I would've gone for 12.6v, too, but the board that you linked to suggests:

Charging voltage: DC 15V CC/CV

So can a board be configured for another voltage than the actual required voltage to charge? So it steps down internally maybe?

Or maybe the data is from a 4S BMS?

New PCB Charger Protect board for 3 Packs 10.8V 11.1V 12.6V 18650 Li ion Lithium Polymer battery Max. 8A w/Balance-in Integrated Circuits from Electronic Components & Supplies on Aliexpress.com | Alibaba Group

Charging voltage: DC 15V CC/CV

So can a board be configured for another voltage than the actual required voltage to charge? So it steps down internally maybe?

Or maybe the data is from a 4S BMS?

New PCB Charger Protect board for 3 Packs 10.8V 11.1V 12.6V 18650 Li ion Lithium Polymer battery Max. 8A w/Balance-in Integrated Circuits from Electronic Components & Supplies on Aliexpress.com | Alibaba Group

use >15V (Pout< 15W) in Discount F85 Lm2596 Led Driver Dc Dc Step Down Adjustable Cc/Cv Power Supply Module From China | Dhgate.Com

adjust CC/CV before connecting to BMS and batts ~1A /12.3V mayhave to turn current down depending on Vin and how hot the PCB gets. IMO should work great at Vin 17V to 22V solar panel?

adjust CC/CV before connecting to BMS and batts ~1A /12.3V mayhave to turn current down depending on Vin and how hot the PCB gets. IMO should work great at Vin 17V to 22V solar panel?

Last edited:

use >15V (Pout< 15W) in Discount F85 Lm2596 Led Driver Dc Dc Step Down Adjustable Cc/Cv Power Supply Module From China | Dhgate.Com

adjust CC/CV before connecting to BMS and batts ~1A /12.3V mayhave to turn current down depending on Vin and how hot the PCB gets. IMO should work great at Vin 17V to 22V solar panel?

Interesting with that solar panel. Might add that at to the setup at some point.

Now; I've never used an adjustable psu, so I have a few question again (sorry for all those questions. I'm learning 😱 )

1: Is the output voltage dependent on the input voltage? Ex will the output voltage remain the adjusted (say 10v) even when the input varies between 12v and 30v? (Related to the solar panel possibility).

2: How close can Vin get to Vout? I'm going to allow my setup to switch between DC in and batteries. The TA2024 have a max Vin at ~14v. Will 14v Vin on the psu be enough to have a Vout of 12.6v?

3: Why did you put 12.3v, when the max voltage of the li-ion bats are 12.6v in 3S? Any reason for this? To spare the batteries or something? 🙂

1st do some basic research and read the data sheet. "DC to DC buck converters"

then you can use me for advanced questions

https://www.youtube.com/watch?v=CEhBN5_fO5o

the most fundamental thing about SMPS is the input looks like a constant power device. as Vin rises Iin decreases etc. The output voltage is regulated until current limits are reached. always study the published PS efficiency curves for clues on applications.

then you can use me for advanced questions

https://www.youtube.com/watch?v=CEhBN5_fO5o

the most fundamental thing about SMPS is the input looks like a constant power device. as Vin rises Iin decreases etc. The output voltage is regulated until current limits are reached. always study the published PS efficiency curves for clues on applications.

Last edited:

dpends on battery chemistry and details of the equalization part of the BMS design.3: Why did you put 12.3v, when the max voltage of the li-ion bats are 12.6v in 3S? Any reason for this? To spare the batteries or something?

for most part Li cells don't like being at or above their spec'd Vmax for long periods.

the older 18650 batteries I use 4.1 V is the limit I shoot for.

also you can trade increased battery life cycles for slightly reduced capacity> lowerd Vmax and/ or DoD. going from 4.1 to 3.9 may triple lifetimes, there is data somewhere

Last edited:

Yeah, Panasonic got 18650 that will do 3500 cycles with only 10% loss in capacitance. But they're rated for 1100mAh at 4.0V max.

Dr mord can you give us details on BMS stuff. regarding set points etc it only works at 4.2 per cell?

overcurrent discharge set point is specified any other user tips appreciated. I haven't tried any.

Does any BMS PCB have load cut-off say at a user defined V set point? this would be very useful I think. and still remain connected to input waitng for the sun (charger) to come out.

any links data sheets I can read up on

overcurrent discharge set point is specified any other user tips appreciated. I haven't tried any.

Does any BMS PCB have load cut-off say at a user defined V set point? this would be very useful I think. and still remain connected to input waitng for the sun (charger) to come out.

Xcellent! Panasonic and Sanyo are leading the packYeah, Panasonic got 18650 that will do 3500 cycles with only 10% loss in capacitance. But they're rated for 1100mAh at 4.0V max.

any links data sheets I can read up on

So I've been reading up on it and watched that video (great video, thanks for that). Looked at a couple of datasheets for the chips, too.

I found this CC/CV:

Free Shipping 5A Adjustable Power CC/CV Step down Charge Module LED Driver Voltmeter Ammeter-in Integrated Circuits from Electronic Components & Supplies on Aliexpress.com | Alibaba Group

This works just as well as the other, right? Just with displays. I do have a multimeter, but it's a cheap one.

So my plan now is to power the portable system with an old laptop charger of 19v. I have a 150w step-down module lying around, which I will put before the TA2024 and step it down to ~13v.

Then the CC/CV in parallel with the step-down module to charge the batteries through the BMS while the speaker is powered by DC.

One question from earlier:

The BMS says it required 15v CC/CV input itself. So shouldn't it be powered by 15v and not 12.6v?

I found this CC/CV:

Free Shipping 5A Adjustable Power CC/CV Step down Charge Module LED Driver Voltmeter Ammeter-in Integrated Circuits from Electronic Components & Supplies on Aliexpress.com | Alibaba Group

This works just as well as the other, right? Just with displays. I do have a multimeter, but it's a cheap one.

So my plan now is to power the portable system with an old laptop charger of 19v. I have a 150w step-down module lying around, which I will put before the TA2024 and step it down to ~13v.

Then the CC/CV in parallel with the step-down module to charge the batteries through the BMS while the speaker is powered by DC.

One question from earlier:

The BMS says it required 15v CC/CV input itself. So shouldn't it be powered by 15v and not 12.6v?

ideally the BMS board wont intervene if your charger, and load don't exceed the safety parameter of a single cell in the string (see BMS spec) given the cells are well matched in the beginning. E.g. set up the charger to match your cells. (Use 3 x 4.1 max) how well your BMS board works IDK, buy one and test all the functionality. Note By testing these BMS thingys, you may weaken some cells by stressing them near the limits esp if they don't work as advertised.

Last edited:

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Li-ion in series/parallel (charging, switch)