I live in the USA and picked up what appears to be an unused Elac 10H turntable produced circa 1965. It features the legendary Papst hysteresis motor.

I'm experiencing a speed issue in which the turntable is running about 2.4x fast per a given speed. For example, at the 33 RPM setting, my strobe disc shows the platter is rotating at a consistent 80 RPM.

I checked the idler wheel and it perfectly aligns with each of the speed steps on the pulley (16,33,45 and 78), so I was able to rule out a misaligned idler wheel as the cause of the speed issue.

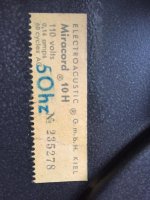

The printed serial number sticker says "110 volts, 0,14 amps, 60 cycles AC." However, at "50Hz" is stamped on top of the sticker in blue whereas the rest of the text is printed. Perhaps this is why the unit is unused as the US is 60Hz. This may indicate that the motor has a 50Hz pulley instead of 60Hz. However, a 50Hz pulley used in the US (60Hz) should only result in a speed deviation of a few percent.

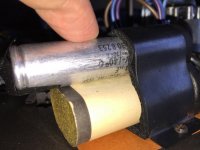

I'm unclear on what is causing this unit to run 140% fast. When comparing capacitors on this unit to known 60Hz 10h models on eBay, I see that my 50Hz unit has what appears to be extra 1uF silver capacitor piggybacked on top of another paper capacitor. Unclear if this is a causal factor or if any of the three capacitors used are leaking or dried up and if that could explain the massive speed overrun.

Any help on how to achieve correct pitch beyond a potential 60Hz pulley would be greatly appreciated.

Here are some pictures and I found a couple of schematics of the 110V and 220V versions. Unclear if my 50Hz unit is 110V vs 220V as the sticker says 110V but has a 50Hz stamp on top of it.

Thoughts?

I'm experiencing a speed issue in which the turntable is running about 2.4x fast per a given speed. For example, at the 33 RPM setting, my strobe disc shows the platter is rotating at a consistent 80 RPM.

I checked the idler wheel and it perfectly aligns with each of the speed steps on the pulley (16,33,45 and 78), so I was able to rule out a misaligned idler wheel as the cause of the speed issue.

The printed serial number sticker says "110 volts, 0,14 amps, 60 cycles AC." However, at "50Hz" is stamped on top of the sticker in blue whereas the rest of the text is printed. Perhaps this is why the unit is unused as the US is 60Hz. This may indicate that the motor has a 50Hz pulley instead of 60Hz. However, a 50Hz pulley used in the US (60Hz) should only result in a speed deviation of a few percent.

I'm unclear on what is causing this unit to run 140% fast. When comparing capacitors on this unit to known 60Hz 10h models on eBay, I see that my 50Hz unit has what appears to be extra 1uF silver capacitor piggybacked on top of another paper capacitor. Unclear if this is a causal factor or if any of the three capacitors used are leaking or dried up and if that could explain the massive speed overrun.

Any help on how to achieve correct pitch beyond a potential 60Hz pulley would be greatly appreciated.

Here are some pictures and I found a couple of schematics of the 110V and 220V versions. Unclear if my 50Hz unit is 110V vs 220V as the sticker says 110V but has a 50Hz stamp on top of it.

Thoughts?

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Here's a comparison pic of a 60Hz Elac 10H for the US market I found online to my 10H unit rated at 50Hz. Notice that the 60Hz version lacks the piggybacked silver can cap on the 50Hz unit (my unit). The third image is an Ero cap that appears to be common to all versions. This Ero cap is tethered to the ignition switch. Thoughts?

Below: 60Hz US Elac 10H (not my unit):

Below: 50Hz Elac 10H (my unit). Note "piggybacked" silver can cap.

Below: 50Hz Elac 10H (my unit). This Ero cap appears to be tethered to the ignition switch and appears to also be present in the 60Hz units.

Below: 60Hz US Elac 10H (not my unit):

An externally hosted image should be here but it was not working when we last tested it.

Below: 50Hz Elac 10H (my unit). Note "piggybacked" silver can cap.

An externally hosted image should be here but it was not working when we last tested it.

Below: 50Hz Elac 10H (my unit). This Ero cap appears to be tethered to the ignition switch and appears to also be present in the 60Hz units.

An externally hosted image should be here but it was not working when we last tested it.

In case the images weren't visible, I've attached them.

Attachments

-

IMG_0201.jpg74.8 KB · Views: 85

IMG_0201.jpg74.8 KB · Views: 85 -

IMG_0202.jpg85 KB · Views: 99

IMG_0202.jpg85 KB · Views: 99 -

IMG_0214.jpg67.6 KB · Views: 106

IMG_0214.jpg67.6 KB · Views: 106 -

IMG_0170.jpg76.6 KB · Views: 97

IMG_0170.jpg76.6 KB · Views: 97 -

IMG_0325.jpg64.1 KB · Views: 91

IMG_0325.jpg64.1 KB · Views: 91 -

IMG_0339.jpg70.5 KB · Views: 78

IMG_0339.jpg70.5 KB · Views: 78 -

115v60hz.jpg81.6 KB · Views: 90

115v60hz.jpg81.6 KB · Views: 90 -

220v50hz.jpg79.5 KB · Views: 83

220v50hz.jpg79.5 KB · Views: 83 -

elac10H-60hz.jpg75.9 KB · Views: 87

elac10H-60hz.jpg75.9 KB · Views: 87 -

elac10H-50hz.jpg69.8 KB · Views: 85

elac10H-50hz.jpg69.8 KB · Views: 85

Hi,

The only way it can run very fast is a reduction in the number of

effective poles, a fault I've never seen and can't comment on.

I presume you mean synchronous for hysteresis.

rgds, sreten.

However 2.4 is exactly double 1.2, and 1.2 is the ratio

of 60Hz to 50Hz, so at a guess you have the wrong

pulley, a 50Hz pulley, and only one half of the windings

connected to 115VAC, when they should be parallel.

Or its simply running at 40rpm, x1.2 fast.

The only way it can run very fast is a reduction in the number of

effective poles, a fault I've never seen and can't comment on.

I presume you mean synchronous for hysteresis.

rgds, sreten.

However 2.4 is exactly double 1.2, and 1.2 is the ratio

of 60Hz to 50Hz, so at a guess you have the wrong

pulley, a 50Hz pulley, and only one half of the windings

connected to 115VAC, when they should be parallel.

Or its simply running at 40rpm, x1.2 fast.

Last edited:

Here are the reposted images with comments as I don't think they displayed earlier due to my error.

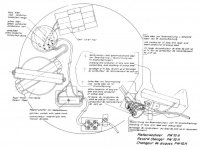

Below 115V/60Hz from service manual.

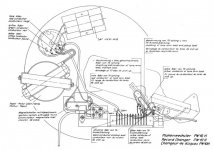

Below 220V/50Hz from service manual.

Image below a 60HZ 10H (NOT MY UNIT). Note absence of silver piggybacked capacitor.

My unit below (50Hz). Note presence of silver "piggybacked" capacitor.

And the Ero cap on my unit tethered to the ignition switch that appears to be common to both the 50Hz and 60Hz units.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Below 115V/60Hz from service manual.

An externally hosted image should be here but it was not working when we last tested it.

Below 220V/50Hz from service manual.

An externally hosted image should be here but it was not working when we last tested it.

Image below a 60HZ 10H (NOT MY UNIT). Note absence of silver piggybacked capacitor.

An externally hosted image should be here but it was not working when we last tested it.

My unit below (50Hz). Note presence of silver "piggybacked" capacitor.

An externally hosted image should be here but it was not working when we last tested it.

And the Ero cap on my unit tethered to the ignition switch that appears to be common to both the 50Hz and 60Hz units.

An externally hosted image should be here but it was not working when we last tested it.

Hi,

The only way it can run very fast is a reduction in the number of

effective poles, a fault I've never seen and can't comment on.

I presume you mean synchronous for hysteresis.

rgds, sreten.

However 2.4 is exactly double 1.2, and 1.2 is the ratio

of 60Hz to 50Hz, so at a guess you have the wrong

pulley, a 50Hz pulley, and only one half of the windings

connected to 115VAC, when they should be parallel.

Or its simply running at 40rpm, x1.2 fast.

Found this in the German Elac 10H service manual and ran it through Google translate. Not sure if the translation is 100% accurate. My unit is a "10H" not the "10." Does this language indicate I would have to change out the motor -- or just the wiring and phase capacitor?

An externally hosted image should be here but it was not working when we last tested it.

Mains Connection

To connect the power cord is on the bottom of the chassis plate, a two-pole terminal strip (s. Fig. 3) attached to a two-wire power cord must be connected with plugs. One check before inserting the power plug whether the existing mains voltage and frequency correspond to the data on the nameplate of the appliance.

Devices MIRACORD 10 are only for mains frequency 60 Hz supplied. However, a switch from 110 volt mains voltage to 220 V by connecting the two winding halves of the engine - instead of the parallel connection at 110 V mains voltage - possible (see enclosed circuit diagram). When executing MIRACORD 10H is a change from 110 to 220 V and vice versa and such from 60 to 50 Hz and vice versa always only be achieved by replacing the entire engine and the phase capacitor.

Found this in the German Elac 10H service manual and ran it through Google translate. Not sure if the translation is 100% accurate. My unit is a "10H" not the "10." Does this language indicate I would have to change out the motor -- or just the wiring and phase capacitor?

An externally hosted image should be here but it was not working when we last tested it.

Mains Connection

To connect the power cord is on the bottom of the chassis plate, a two-pole terminal strip (s. Fig. 3) attached to a two-wire power cord must be connected with plugs. One check before inserting the power plug whether the existing mains voltage and frequency correspond to the data on the nameplate of the appliance.

Devices MIRACORD 10 are only for mains frequency 60 Hz supplied. However, a switch from 110 volt mains voltage to 220 V by connecting the two winding halves of the engine - instead of the parallel connection at 110 V mains voltage - possible (see enclosed circuit diagram). When executing MIRACORD 10H is a change from 110 to 220 V and vice versa and such from 60 to 50 Hz and vice versa always only be achieved by replacing the entire engine and the phase capacitor.

The H version is the hysteresis ,synchrone,motor speed fixed thus other pulley for 60 hz and other phase cap.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Papst motor running 2.4x fast: Elac 10H 50Hz