Demian,

Somewhere on this thread or in another we had this discussion with Sy and if I remember that correctly he stated there are no plasticizers added to the material in an album. There were no materials to leach out of the materials used, especially by a water reaction. Only thing the water would do is leave mineral deposits if it was not DI water.

I don't think I said that about LPs- there's certainly plasticizers in their PVC compound. I did say that there isn't an external mold release used in the process, which may be what you're remembering.

Water will not leach out carbon, but it might leach out other things in the PVC compound. And yes, unless the water is insanely pure, it will leave behind some residue. I have an experiment in mind...

Steven,

Look for SY’s posts in this thread:

http://www.diyaudio.com/forums/analogue-source/220542-riders-storm.html

One correction: since that time, I determined that apparently no-one uses external mold release, it's only internal; this was discussed a few months ago, I think in this thread.

A couple years in that business taught me at least that. 😀

Thank you SY.

See this one:

Turntable Forum • Shure V15Vx + JICO SAS antiskate measurements ± brush

If there is anything to come out of measuring record alone vs record with cartridge running on it, it is necessary to take a number of measurements –at least 5- and average the results.

And have the platter rotate more than half an hour before starting the measurements.

George

I like the deceleration method. 😉

But you need to know the inertia of the total rotational system rather accurately.

Patrick

See this one:

Turntable Forum • Shure V15Vx + JICO SAS antiskate measurements ± brush

If there is anything to come out of measuring record alone vs record with cartridge running on it, it is necessary to take a number of measurements –at least 5- and average the results.

And have the platter rotate more than half an hour before starting the measurements.

George

> Would it not be possible to calculate the energy from the friction of the needle over the vinyl? We know dimensions of the tip, tip force, tracking speed ...?

There is a simpler way Jan. 😉

Just measure the increase in current of the turntable motor.

Multiply by the voltage, then you have the value you want.

Patrick

But that only gives total loss, and besides likely being a difficult small difference of large thing to measure.

This is a fascinating history of wire gauge measurements: The story of the gauge - P[]ll - 2002 - Anaesthesia - Wiley Online Library Gauge seems to mostly relate to how many times the wire was passed through a drawing die. It actually makes sense even if not relating to familiar dimensions.

Sheet metal is also gauged originally by the number of passes under a specific roller.

fyi

jn

Attachments

jn

Is this the result of your measurements?

For Scott and anyone else interested in rumble (and rev velocity stability) measurement without using the 3150Hz track of a test record. Pages 16-18:

http://www.americanradiohistory.com/Archive-DB-Magazine/60s/DB-1968-03.pdf

A lot of -now- lost knowledge regarding tape/disk recording technology can be found in these archives.🙂

George

Is this the result of your measurements?

For Scott and anyone else interested in rumble (and rev velocity stability) measurement without using the 3150Hz track of a test record. Pages 16-18:

http://www.americanradiohistory.com/Archive-DB-Magazine/60s/DB-1968-03.pdf

A lot of -now- lost knowledge regarding tape/disk recording technology can be found in these archives.🙂

George

Last edited:

jn

Is this the result of your measurements?

George

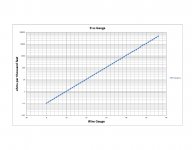

No. It's one of my excel spreadsheets, culled from online data available at mws wire.

I first made a sheet from the gauge to mm chart page 31, then calculated the cross sectional area from the inches diameter, then inverted to get a scaled resistance, then divided that by 114 to get to the actual conductor per foot resistance. I then verified that it matched very closely the gauge to resistance values specified on page 4.

I tried several things to get the 1/0 through 5/0 to work on the spreadsheet, but it kept doing very weird things. I suspect it is because I assigned negative numbers to the oughts for the graph...-1 for 1/0, -2 for 2/0, etc (I was proud of thinking that up, until the graph puked on me..). Even though the y axis is logarithmic and the x axis linear, the graph did not behave when I included negative gauges. I suspect the log y axis to be the culprit.

Welcome to MWS Wire Industries

http://www.mwswire.com/pdf_files/mws_tech_book/page31.pdf

http://www.mwswire.com/pdf_files/mws_tech_book/page4.pdf

ps.. I did this a while ago to calculate the pulse ampacity of small copper wires in a liquid helium environment, when subjected to a high current pulse with a time constant. While large guage wires are best for 200-400 amp pulses running a decay constant of 4 or 5 seconds, they conduct heat from the cold to room temp.(edit:the fridge consumes 1000 watts for every watt of heat loss at 4K, 2000 watts per watt at 1.8K, so heat loss through overly large wire gauge is a major concern) It required also the heat capacity and conductivity of copper from room to 4K. Turns out a 24 gauge wire can survive a 400 amp 4 second time constant pulse easily, and it won't exceed room temp.

jn

Last edited:

Sy and George thanks for the information, sorry I mis-remembered the plasticizer information. Sy, from what I have observed the internal mold releases continue to leach to the surface of a molded plastic compound long after molding. Most of the compounds I am familiar with were some form of synthetic micro-crystalline waxes that were not part of the polymer matrix, but were just in suspension within the polymer compound. If this is the same in a pvc material how would that change the surface of the material over time? I would think that the surface tension of the material would change or the lubricity would modulate depending on time and temperature?

Are we sure that the deceleration time is a good measure? Remember that lubricant friction changes with velocity. Also, depending on how the motor is connected it may or may not apply a sort of E-brake action which itself may not be linear.

AWG

Interesting how the numbers all line up with US dimensions. Its very very American. . .

This table doesn't follow the numbers quite as accurately American Wire Gauge (AWG) Cable Conductor Size Chart / Table

Looking at this American wire gauge - Wikipedia, the free encyclopedia (given that the AWG numbers originated in 1857) resistance was not a significant factor in determining the diameter. However the 10X ratio is a useful rule of thumb anyway.

fyi

jn

Interesting how the numbers all line up with US dimensions. Its very very American. . .

This table doesn't follow the numbers quite as accurately American Wire Gauge (AWG) Cable Conductor Size Chart / Table

Looking at this American wire gauge - Wikipedia, the free encyclopedia (given that the AWG numbers originated in 1857) resistance was not a significant factor in determining the diameter. However the 10X ratio is a useful rule of thumb anyway.

Some of this was put into the AES Journal in the middle to late '60's.

JAES J, Audio M, WW M,...

George

Attachments

No. It's one of my excel spreadsheets,

Thanks jn

Logarithm of a number x<0 is undefined, so the spreadsheet gets mad or refuses to accept your trick 😉

>Edit: Pay a visit to this page

http://www.ultracad.com/articles/wiregauge.pdf

(bonus): MWS has a nice tool for diy litz wire calculation:

MWS Wire Industries - LITZ Wire Tool

George

Last edited:

The AES Journal paper is: 'Sensitivity of Phonograph Turntable to Normal Loads' T.S. Cole, Sr. pp. 448-450 year-1967

Last edited:

Thanks jn

Logarithm of a number x<0 is undefined, so the spreadsheet gets mad or refuses to accept your trick 😉

I know. I kept the x axis linear scale so it could go negative thinking that gee, it's only a straight line, why can't it figger it outs???? It worked great on my screen, the felt tip pen writing on the screen looked perfect..😉

I'll check out the litz thing, thanks.. I just finished assembling 360 coils using honkin high count litz and I suspect there will be more.

edit: they only go down to 18 gauge??? All my coils were 15 gauge equiv..

We used Cooners. They go down to 2AWG in type 5 litz. We used a bunch of that about 10 years ago for a neat magnet. I just used 15 gauge type 3 for my coils.

http://www.coonerwire.com/litz-wire/

Holy mackerel, type 6 goes up to 525 KCMIL!!! That's about an inch diameter, 21 thousand strands of #36. All my speaker cable needs have finally been addressed!!!!

Let's do a group order right now!!

jn

Last edited:

It worked great on my screen, the felt tip pen writing on the screen looked perfect..😉

Talking about cutting the Gordian knot.

😀

😀George

Holy mackerel, type 6 goes up to 525 KCMIL!!! That's about an inch diameter, 21 thousand strands of #36. All my speaker cable needs have finally been addressed!!!!

Let's do a group order right now!!

jn

One of our guys set up a demo for current measurement in e-cars. He used some new copper-clad aluminum mutistrand, you can jump rope with #0. The battery was simulated with a 12,000F supercap, impressive, you can draw a spark with only 50mV charge!

> you can draw a spark with only 50mV charge!

Just like the noise in a poor connection .......

Just like the noise in a poor connection .......

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II