43dB is 141 times magnification. 63dB is 1410 times magnification. Wow, imagine if there is dirt on that lens. Still amazing how chisel carving a master then stamping it on a cheap plastic then dragging a rock on it then zooming out hard on its hand waving and EQing at the same time plays any legible music at all.

True that. You nailed it!

Come to think of it, i didnt touch the cap. I will try that and see. And an off topic question: What are your speakers?

Self designed three way towers with modded Audax tweeter, PHL 6 inch pro sound mid-woofer, double car audio ovals 6x9 Tangband per side. Boxes are sitting on top of another as separate builds. There is a step back for aligning the tweeter.

SCOTCHBRITE pads are good for removing corrosion

Seems to be more gentle than the finest sandpaper. Leaves no visible scratches.

I use them to clean up the leads of components before insertion.

Even new components leads are shinier after some scrubbing. A revelation with old ones ...

There had been mention of methods. I, too, would be too impatient to wait for tomato acid to do the work.

Seems to be more gentle than the finest sandpaper. Leaves no visible scratches.

I use them to clean up the leads of components before insertion.

Even new components leads are shinier after some scrubbing. A revelation with old ones ...

There had been mention of methods. I, too, would be too impatient to wait for tomato acid to do the work.

Tomato acid is left a bit on to react first but there is also rubbing off the tarnish with ketchup aggressively using a paper towel afterwards. We would like to see photos from your special and elaborate vinyl rig also when you will be ready with the phono BTW.

For circular leads I hold them inside grooves of some pliers and turn them. This is also a good way to strip solder from leads to get them back to their original size.

I use a fine cutter to polish the components wires... quite effective also.

Off board riaa filter already done 🙂

Will use Ft-3 for interstage off course.

Off board riaa filter already done 🙂

Will use Ft-3 for interstage off course.

I suspect that any effect due to correcting +0.45g error on a 1.5g spec cart will be maximal. Happy listening soon and let us know.

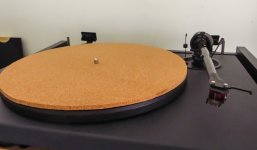

Played some records today after re-verifying tracking force (1.6g). Some interesting results. Slight improvement in bass, it lost some of that "lean" quality, so better balance overall. Also got rid of a slight channel imbalance I had noticed previously. The "sound stage" got wider, and more centered, where before it was kind of crowding the left speaker. Still some tizziness or sibilance on some tracks, but now I'm wondering if I can fix it just with better VTA. I have been thinking of making a cork platter mat, and making it thick enough to correct the slight nose-down alignment. If I can just find a local supplier of cork sheets in the right thicknesses...

I use a fine cutter to polish the components wires... quite effective also.

Off board riaa filter already done 🙂

Will use Ft-3 for interstage off course.

What is "Ft-3 for interstage"? Did I miss anything?

ATAP.... 🙂Make it very tight not to lose the board's layout noise and resolution benefits.

Played some records today after re-verifying tracking force (1.6g). Some interesting results. Slight improvement in bass, it lost some of that "lean" quality, so better balance overall. Also got rid of a slight channel imbalance I had noticed previously. The "sound stage" got wider, and more centered, where before it was kind of crowding the left speaker. Still some tizziness or sibilance on some tracks, but now I'm wondering if I can fix it just with better VTA. I have been thinking of making a cork platter mat, and making it thick enough to correct the slight nose-down alignment. If I can just find a local supplier of cork sheets in the right thicknesses...

Very nice improvement. I have noticed channel imbalance when carts are at wrong VTF too. Why not a test at 1.5g also. How many mm thickness you need for neutral VTA? Also have a look on ebay for cork turntable mat. There is quite a collection and variation to find and some thickness range too. Label recess and edgeless support for the vinyl record are essential features IMHO. Same effect for label and edge happens if distributed small discs or slices are there as cork toppings.

Very nice improvement. I have noticed channel imbalance when carts are at wrong VTF too. Why not a test at 1.5g also. How many mm thickness you need for neutral VTA? Also have a look on ebay for cork turntable mat. There is quite a collection and variation to find and some thickness range too. Label recess and edgeless support for the vinyl record are essential features IMHO. Same effect for label and edge happens if distributed small discs or slices are there as cork toppings.

Yes, my plan is to use 2 layers, a thicker one (say 3/16") which is an exact copy of the thorens mat, and a thinner top layer (like 1/16") with slightly smaller diameter and larger center hole for the label. Either contact cement or silicone adhesive to join them. I am hoping an automotive parts place might have sheets of cork gasket material.

Since i couldnt find a proper size screwdriver to adjust the VTA, i thought about nezbleu's idea (thanks!) for a thicker cork mat and bought a 5mm thick cork sheet. Actually i figured i would need 4mm for proper VTA but 5mm was the nearest i could find.

The tonearm appears to be perfectly parallel to the vinyl surface, and the sound is more "relaxed". Drawback is that the tonearm in playing position is higher than the tonearm lift mechanism, so the needle always touches the vinyl surface.

The tonearm appears to be perfectly parallel to the vinyl surface, and the sound is more "relaxed". Drawback is that the tonearm in playing position is higher than the tonearm lift mechanism, so the needle always touches the vinyl surface.

Attachments

I wonder why they come out with a TT model that has to be wrongly aligned for its lift rest to work. Is there is a set screw by any luck that could fix the lift mechanism bit higher? Maybe you could find 3mm thick cork (rubber mixed cork also) plus 1mm neoprene to add a layer with label cut out.

Maybe you could stick something on the arm lift bar, like some self-adhesive cork or rubber, or a little piece on the underside of the arm, to reduce that clearance.

PS: Where did you get the cork sheet?

PS: Where did you get the cork sheet?

I bought the cork sheet locally from a chain of stores that sells computers , tv's,

but they also sell accesories for graphic arts (paints, pencils etc etc). It's called Plaisio.

There is a screw in the top of the arm lift, and i did try rotating it but it just seems to unscrew the lift.

I attach a photo of the tonearm. In the red circle is one of two screws that adjusts the VTA. Well everything would be ok if could find the right size for that screw. The arm lift would work ok in a lower position of the whole arm (plus with a thinner cork mat)

but they also sell accesories for graphic arts (paints, pencils etc etc). It's called Plaisio.

There is a screw in the top of the arm lift, and i did try rotating it but it just seems to unscrew the lift.

I attach a photo of the tonearm. In the red circle is one of two screws that adjusts the VTA. Well everything would be ok if could find the right size for that screw. The arm lift would work ok in a lower position of the whole arm (plus with a thinner cork mat)

Attachments

In the meanwhile i'll just stick something in the lift to reduce clearance and keep looking for the right tool to adjust the VTA.

The "High-end" sound store that adjusted my TT for the Denon DL160 some years back did an "amazing" job (not!). Probably because they dont sell Denon's

The "High-end" sound store that adjusted my TT for the Denon DL160 some years back did an "amazing" job (not!). Probably because they dont sell Denon's

Write to Pro-Ject they should tell you what wrench you need for that screw (it should have come packed with the TT is the right thing).

- Home

- Source & Line

- Analogue Source

- Simplistic NJFET RIAA