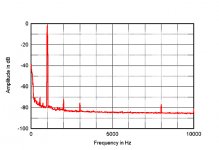

Depends. In case of digital nastiness uncorrelated/correlated to program you will hear it even if lines (not SINGLE line) are about -90dB or less. Sounds like chirps, best heard with headphones during low level parts of music.

I have a player with digital noise at -90dB and it's easy to hear during quiet passages like you say, sounds like chirps.

Quad electrostatics having 100th the distortion of a normal moving coil speaker I have a hard time with that? Try and make any type of lower frequencies with them and tell me that is true.

For low bass... then, all bets are off. response is down 6dB at 30Hz. But still 100db at 1 meter spec is under <1% at 50Hz is excellent.

-RM

Last edited:

This is the (older) ESL 63, or one of the new models the 2812 or the (bigger) 2912 ?

For the 2912 Quad claims an incredible 0.1% distortion for 100 Hz at 90dB/1m.

For the 2912 Quad claims an incredible 0.1% distortion for 100 Hz at 90dB/1m.

Last edited:

I'll go out on a limb and state the QUAD is the lowest distortion speaker ever made.

View attachment 402168

Thx-RNMarsh

This is pretty good. What is that 8th??

It would be nice to know which model in discussion RNM, the 63 tested many years ago had very low distortion, the new ones are supposedly better..

Has not this fetish for burn in come from burn in testing that most life/mission critical equipment has to go through, it is a part of the specification for all class 3 based electronics I have worked on, and is to stress the whole assembly at the specified operating conditions including often severe changes of temperature...

Quite a bit lower...maybe a 100 times lower than 1%.

-RNM

Who are you kidding, you guys don't listen at "Quad" levels especially in the bass. Look I'm not talking about digital hash. Component non-linearities are inherently low order and HAVE to appear at the same frequencies as each other. The same argument that lots of them add up to audibility, could be used to claim removing any one of them is inaudible. You can't have it both ways i.e. removing one nasty magnetic resistor lifts a dozen "veils".

Last edited:

Has not this fetish for burn in come from burn in testing that most life/mission critical equipment has to go through, it is a part of the specification for all class 3 based electronics I have worked on, and is to stress the whole assembly at the specified operating conditions including often severe changes of temperature...

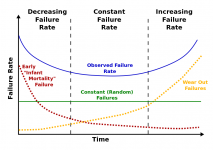

Yes it is related to the well-known (to some) 'bath tub' failure curve. Typically, electronics fail either very early (infant mortality) or very late in their life time (old age). So with burn in you want to weed out the infant mortality failings, which makes the rest work reliably for many, many years.

Has nothing to do with (sound) quality.

One thing I do find curious (or maybe not) is why burn-in always improves stuff, never makes it worse...

Jan

Attachments

Last edited:

Burn-in of audio electronics is based on physics, rather than engineering. Cryoing does something similar and can speed up the burn-in time if used.

Burn-in of audio electronics is based on physics, rather than engineering. Cryoing does something similar and can speed up the burn-in time if used.

Again there is evidence of physical processes in a field having nothing to do with audio and the connection to audibility is immeadiately made, same with quantum effects. I guess it makes for good stories and add copy.

I find that advanced understanding of some topics of physics is VERY useful in making better audio products.

Please buy a copy of Forwood's book, or go to your local technical library and read the pages I referenced, then we will have something to discuss.

Please buy a copy of Forwood's book, or go to your local technical library and read the pages I referenced, then we will have something to discuss.

I find that advanced understanding of some topics of physics is VERY useful in making better audio products.

Please buy a copy of Forwood's book, or go to your local technical library and read the pages I referenced, then we will have something to discuss.

Preventing the SEM beam from modifying the surface being examined is a standard problem John. Anybody can zap the surface during viewing. It's the finess that prevents surface changes.

You claiming some magical process after reading some bog standard SEM methodology issues is tired and old.

You tried this schtick many years ago, it was shot down then as well.

jn

Forwood

The first 90 pages are available on Google books:

Electron Microscopy of Interfaces in Metals and Alloys - C.T Forwood, L.M Clarebrough - Google Books

Ray

I find that advanced understanding of some topics of physics is VERY useful in making better audio products.

Please buy a copy of Forwood's book, or go to your local technical library and read the pages I referenced, then we will have something to discuss.

The first 90 pages are available on Google books:

Electron Microscopy of Interfaces in Metals and Alloys - C.T Forwood, L.M Clarebrough - Google Books

Ray

Thanks rayma. Unfortunately, pp 315-325 is not easily available. However, the book IS purchasable used, that is how I got my copy.

Here are two pages. The second page states that the mechanism is NOT due to the Electron microscope, so there! '-)

Here are two pages. The second page states that the mechanism is NOT due to the Electron microscope, so there! '-)

So, how does he prove it's not induced by beam heating?

How does one take a picture of an object using a beam that can change the object, yet claim that the picture of a change was not caused by the beam being used??

Are you always that gullible John??😉

If you really want to look at surface energy stuff, look up tin whiskers.

That'll fry your brain..

That, and toyota unintended acceleration.

jn

Last edited:

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II