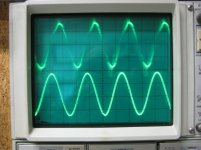

Here is a side by side of the E50 plot (taken in TD124 sn 2729) and the Papst plot (taken in sn 13943)

Steve as you see on the picture I"m bussy with the E50 /Papst motor and the vibration measurements on the TD 124 chassis.

The protype analog3 phase powersupply is ready and I made measurements between the Siemens micromaster 420 inverter.

Lot off work but very interesting to see that every rotating component produced his own vibrating spectrum and that the TD124 has a complex drivetrain.

Next days I show the results.

Volken

Steve as you see on the picture I"m bussy with the E50 /Papst motor and the vibration measurements on the TD 124 chassis.

The protype analog3 phase powersupply is ready and I made measurements between the Siemens micromaster 420 inverter.

Lot off work but very interesting to see that every rotating component produced his own vibrating spectrum and that the TD124 has a complex drivetrain.

Next days I show the results.

Volken

Attachments

Here is a side by side of the E50 plot (taken in TD124 sn 2729) and the Papst plot (taken in sn 13943)

Steve as you see on the picture I"m bussy with the E50 /Papst motor and the vibration measurements on the TD 124 chassis.

The protype analog3 phase powersupply is ready and I made measurements between the Siemens micromaster 420 inverter.

Lot off work but very interesting to see that every rotating component produced his own vibrating spectrum and that the TD124 has a complex drivetrain.

Next days I show the results.

Volken

thanks for contributing to this thread. I look forward to it.

-Steve

The resistor is there only to limit current to the neon lamp, if wired correctly it and the neon appear in parallel with the motor winding and AC mains, no motor current flows through it. It now appears correctly wired to me.

The cleaning and lube seem highly advisable after all this motor is probably 35+ years old. I believe this accounts entirely for the performance improvement you have observed.

I was a bit surprised at the design of the thrust bearing assembly - looks to me like there is considerable room for improvement. I can't imagine it is as quiet as it could be. The bushing in the stator assembly provides the only centering and the bottom of the motor is essentially floating. I assume the external rotor assembly is very carefully balanced otherwise I expect wobble rather than just vibration. On reflection I suspect it would be hard to modify that thrust bearing..

re: motor architecture. It does look a bit "cheap" in the way the thrust end of it assembles. This is the only Papst Aussenlaufer I've seen up close. Perhaps there are other examples of this breed that show more attention to detail in that area. I don't know.

re: motor balance. I do not get any sense of the motor having poor balance. When powered and running the motor appears to spin without any drama or excessive vibes. The only thing I notice is that there is some wind noise coming from it as the individual fins beat against the atmosphere. But that is to be expected. And, for what it is worth, you can hear the motor beating the wind quite clearly while changing records. Perhaps even you can hear it while standing within a few feet of it. Especially if one is listening for it. But that part of it does not appear to intrude upon the signal. So it means little.

re: sound quality. Presently I'm getting a very atmospheric and romantic sound from this unit. Partly this is due to the arm/cartridge combination. And this cartridge does have the conical stylus, which will limit upper frequency detail. Perhaps for the better, I'm thinking, as I enjoy those parts of the groove that it does reproduce.

-Steve

Mesurements are done with the Thorens Rumple Messkoppler on de mainbearing.

I choose not measure with the platter and idler wheel because the idler ads a lot vibration .

The Papst motor and E 50 motor are decoupled in springs !

The Papstmotor has a optimized phasenetwork with capacitor 530 nF and 270 ohm resistor !

The E50 motor has had a complete revision bearings etc.

The Papst has a stronger rotation freq. then the E50 about 10 db!the other peaks are from the steppulley,belt, mains,tonearm and some harmonics.

Volken

View attachment TD124 Spectrum Papstmotor on mains Tunning 530nF270 ohm 100Hz.bmp

View attachment TD124 Spectrum E50 motor after revision 100Hz.bmp

I choose not measure with the platter and idler wheel because the idler ads a lot vibration .

The Papst motor and E 50 motor are decoupled in springs !

The Papstmotor has a optimized phasenetwork with capacitor 530 nF and 270 ohm resistor !

The E50 motor has had a complete revision bearings etc.

The Papst has a stronger rotation freq. then the E50 about 10 db!the other peaks are from the steppulley,belt, mains,tonearm and some harmonics.

Volken

View attachment TD124 Spectrum Papstmotor on mains Tunning 530nF270 ohm 100Hz.bmp

View attachment TD124 Spectrum E50 motor after revision 100Hz.bmp

Mesurements are done with the Thorens Rumple Messkoppler on de mainbearing.

I choose not measure with the platter and idler wheel because the idler ads a lot vibration .

The Papst motor and E 50 motor are decoupled in springs !

The Papstmotor has a optimized phasenetwork with capacitor 530 nF and 270 ohm resistor !

The E50 motor has had a complete revision bearings etc.

The Papst has a stronger rotation freq. then the E50 about 10 db!the other peaks are from the steppulley,belt, mains,tonearm and some harmonics.

Volken

View attachment 402001

View attachment 402002

View attachment 402004

Thanks Volken.

As I suspected, the Papst, even when the capacitor value is optimized, is significantly noisier than the E50. And that measurement isolates the motor from the idler and platter. Useful.

With measurements taken at the bearing we can assume that these additional 10 db of noise will find their way into the musical signal when playing a record!

It is interesting the use of a resistor in combination with a capacitor to fine tune the phase timing.

With the TD124 fully assembled into working trim, I wonder if you can observe start-up times on a cold start and then compare to that with the E50? The reason I ask is that this is something that is happening at my end. With the Capacitor tuning I've done, I find start-up times from cold unreasonably long. I can alter start-up times simply by increasing voltage levels that feed the motor. For example, if I feed the motor 130 volts, start-up times are significantly quicker and almost normal compared to what I get with the E50. But the E50 was getting 120 volts in that comparison.

-Steve

With the TD124 fully assembled into working trim, I wonder if you can observe start-up times on a cold start and then compare to that with the E50?

Steve I will check this with a cold motor these days.

Volken

Steve I will check this with a cold motor these days.

Volken

Measurement 3 phase motorsupply for the Papst first with the Siemens Micromaster 420 with shielded cables and the prototype analog HAT 3 phase supply for Papst and EMT 930 motor .

Volken

View attachment TD124 Spectrum Papstmotor 3 Phase Siemens Micromaster 420 400Hz.bmp

View attachment TD124 Spectrum Papstmotor 3 Phase HAT powersupply 400Hz .bmp

Volken

View attachment TD124 Spectrum Papstmotor 3 Phase Siemens Micromaster 420 400Hz.bmp

View attachment TD124 Spectrum Papstmotor 3 Phase HAT powersupply 400Hz .bmp

Measurement 3 phase motorsupply for the Papst first with the Siemens Micromaster 420 with shielded cables and the prototype analog HAT 3 phase supply for Papst and EMT 930 motor .

Volken

View attachment 402028

View attachment 402029

View attachment 402030

Clearly the spectrum plots favor your HAT 3 phase PS. Can you describe the fundamental differences between the Siemens 420 and your HAT.

-Steve

With the TD124 fully assembled into working trim, I wonder if you can observe start-up times on a cold start and then compare to that with the E50?

I checked the startup time from the E50 in my own TD124 with steel platter its about 1-2 seconds till normal speed.

With the Papst tuned motor a little bit slower about 3-4 seconds ,with the 3phase powersupply 1-2 seconds.

Volken

Hi,

I'm totally lost as to the significance of a 3 phase supply to

a 2 phase motor. As far as understand it a 2 phase motor

needs 90 degrees for minimum vibration. You can't get

90 degrees with a single cap. You can with an active

2 phase supply, and you can passively by adding

some inductance to the winding not fed by the

capacitor. Resistance in the motor circuit return

simply limits start up torque and belt stretch.

rgds, sreten.

I'm totally lost as to the significance of a 3 phase supply to

a 2 phase motor. As far as understand it a 2 phase motor

needs 90 degrees for minimum vibration. You can't get

90 degrees with a single cap. You can with an active

2 phase supply, and you can passively by adding

some inductance to the winding not fed by the

capacitor. Resistance in the motor circuit return

simply limits start up torque and belt stretch.

rgds, sreten.

Hi,

I'm totally lost as to the significance of a 3 phase supply to

a 2 phase motor. As far as understand it a 2 phase motor

needs 90 degrees for minimum vibration. You can't get

90 degrees with a single cap. You can with an active

2 phase supply, and you can passively by adding

some inductance to the winding not fed by the

capacitor. Resistance in the motor circuit return

simply limits start up torque and belt stretch.

rgds, sreten.

It is a three phase motor. This particular Papst. that is why we think it would be optimal to supply it with 3 phase power.

With the TD124 fully assembled into working trim, I wonder if you can observe start-up times on a cold start and then compare to that with the E50?

I checked the startup time from the E50 in my own TD124 with steel platter its about 1-2 seconds till normal speed.

With the Papst tuned motor a little bit slower about 3-4 seconds ,with the 3phase powersupply 1-2 seconds.

Volken

Thanks for checking that.

I'll continue my search to understand what is happening at my end.

Fwiw, all mechanical parts of the drive train have been cleaned and lubed. The stepped pulley spins very freely. So does the idler wheel. And as I have previously noted, the moving parts within the motor have been cleaned and lubed.

I did move the EC magnet back from its previous position, which was fairly close to the driven pulley. Now I've got it approximately .100 inches (uniformly) of distance between the magnet and the driven pulley surface.. And that did seem to reduce times somewhat, but not enough.

Other aspects. apart from voltage going into the motor, which I can adjust, there might be other parameters which may affect this motor's ability to quickly attain correct speed. Amps. Watts, etc.

-Steve

It is a three phase motor. This particular Papst. that is why

we think it would be optimal to supply it with 3 phase power.

Hi,

Really ? I've never seen a 3 phase motor that small

and the the numbers printed on it indicate 2 phase.

Nevermind 3 phase cannot be 115VAC.

Its 415VAC in the UK, and 200VAC in the US.

Also being 16 pole it cannot be a 3 phase motor.

3 phase motors don't need any capacitors to run,

and you will never see a capacitance value on one.

rgds, sreten.

Last edited:

Hi,

Really ? I've never seen a 3 phase motor that small

and the the numbers printed on it indicate 2 phase.

Nevermind 3 phase cannot be 115VAC.

Its 415VAC in the UK, and 208VAC in the US.

Also being 16 pole it cannot be a 3 phase motor.

rgds, sreten.

How do you get 16 pole. Are we looking at the same Papst?

-Steve

Hi, You have a problem counting ?, rgds, sreten.

A 3 phase motor needs 4 wires, not three, OK, delta doesn't but a ludicrous

assumption. Easy enough to measure. Delta will give the same Rdc wire to wire,

2 phase one pair will measure twice as high as the other two, other wire common.

Its very clearly a 2 phase motor, as are all mains synchronous motors in all sound equipment.

Last edited:

Hi, You have a problem counting ?, rgds, sreten.

I guess there is a problem. I count 12 poles on this one. My eyes can't be 'that' bad.

re; the rest of the points you bring up: I'll wait for others to chime in. Keep in mind that Volken is achieving best looking plots using his 3-phase PS. His is the same type of motor, but manufactured for European mains.

-Steve

It is a three phase motor. This particular Papst. that is why we think it would be optimal to supply it with 3 phase power.

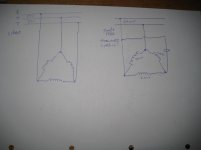

I made a drawing from the Papst motor it can be used on a single phase supply with the so called ,,Steimetz,, circuit and also 3 phase connection.

The coils have a Delta connection all the same resistance it important to get the same voltage on each coil for min.vibration and startup .

For tuning you can use the a CR combination.

Volken

Sreten, The standard E50 motor in a TD-124 is a shaded pole induction motor and my understanding has always been that the replacement Papst motor is a 3 phase induction motor as well - not fully synchronous. Speed is load dependent, and an eddy current brake is used to set the speed. The Garrard 301 and 401 used shaded pole induction motors with eddy current brakes as well. (I have a 401, and spare motor, as well as two running TD-124s)

There are a lot of people in Germany and elsewhere running 3 phase power to Papst motors in EMT tables and TD-124s retrofitted with the Papst. I assume they know what they are doing.

I'm quite interested in the Papst, although its noise performance concerns me a bit. (And they are expensive to acquire and relatively rare.)

I've measured other Papst turntable motors for a couple friends, and these were all delta wound 3 phase motors. (3 wire, same dcr any wire to any other wire)

There are a lot of people in Germany and elsewhere running 3 phase power to Papst motors in EMT tables and TD-124s retrofitted with the Papst. I assume they know what they are doing.

I'm quite interested in the Papst, although its noise performance concerns me a bit. (And they are expensive to acquire and relatively rare.)

I've measured other Papst turntable motors for a couple friends, and these were all delta wound 3 phase motors. (3 wire, same dcr any wire to any other wire)

- Home

- Source & Line

- Analogue Source

- new project: TD124 with the Papst motor