Hi albertli !

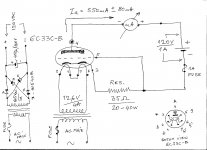

To check 6c33c-b tube condition you need :

1) filament transformer with 6,3 VAC / 8A or 12,6VAC / 4A secondary .

2) regulated or non regulated DC source with 120V which is capable to deliver at least 1A of constant current .

3) one wire wound power resistor 35 ohm / 25 - 50W .

4) quality tube socket and pre cleaned tube pins.

test procedure is simple :

- First power on Transformer for filament supply.

- wait 5 min or even longer to heat up the tube cathodes .

- Than power on 120VDC source and read anode current .

- Reading must be nominal 550mA ,

with allowed factory variation of Plus or Minus 80 mA for each good tube , and that`s practically mean reading of Ia= 630mA Max. , or Ia=470mA Min ,

Any reading in between of this two Min/Max values mean that 6c33c-b tube is OK .

- Reading of anode current have to Not cross time more of 10 second !!!

Best Regards !

To check 6c33c-b tube condition you need :

1) filament transformer with 6,3 VAC / 8A or 12,6VAC / 4A secondary .

2) regulated or non regulated DC source with 120V which is capable to deliver at least 1A of constant current .

3) one wire wound power resistor 35 ohm / 25 - 50W .

4) quality tube socket and pre cleaned tube pins.

test procedure is simple :

- First power on Transformer for filament supply.

- wait 5 min or even longer to heat up the tube cathodes .

- Than power on 120VDC source and read anode current .

- Reading must be nominal 550mA ,

with allowed factory variation of Plus or Minus 80 mA for each good tube , and that`s practically mean reading of Ia= 630mA Max. , or Ia=470mA Min ,

Any reading in between of this two Min/Max values mean that 6c33c-b tube is OK .

- Reading of anode current have to Not cross time more of 10 second !!!

Best Regards !

Attachments

I run my 6C33C at 200V,

Mixed bias.<<You can do this and make use of your low bias voltage!

OTL, and I ran just heaters no HT for 24 Hrs before power up.

I run on one or two heaters in OTL.

And I also found some coating on the tube pins and cleaned with fine emery cloth only a couple of twists. Not file them down.🙂

Probably a good idea to check with a meter on ohms for shorts between the grid/anode/cathode. (Just to be safe before power up)

Regards

M. Gregg

Mixed bias.<<You can do this and make use of your low bias voltage!

OTL, and I ran just heaters no HT for 24 Hrs before power up.

I run on one or two heaters in OTL.

And I also found some coating on the tube pins and cleaned with fine emery cloth only a couple of twists. Not file them down.🙂

Probably a good idea to check with a meter on ohms for shorts between the grid/anode/cathode. (Just to be safe before power up)

Regards

M. Gregg

Last edited:

Great post. Thanks for sharing, much appreciated!Hi albertli !

To check 6c33c-b tube condition you need :

1) filament transformer with 6,3 VAC / 8A or 12,6VAC / 4A secondary .

2) regulated or non regulated DC source with 120V which is capable to deliver at least 1A of constant current .

3) one wire wound power resistor 35 ohm / 25 - 50W .

4) quality tube socket and pre cleaned tube pins.

test procedure is simple :

- First power on Transformer for filament supply.

- wait 5 min or even longer to heat up the tube cathodes .

- Than power on 120VDC source and read anode current .

- Reading must be nominal 550mA ,

with allowed factory variation of Plus or Minus 80 mA for each good tube , and that`s practically mean reading of Ia= 630mA Max. , or Ia=470mA Min ,

Any reading in between of this two Min/Max values mean that 6c33c-b tube is OK .

- Reading of anode current have to Not cross time more of 10 second !!!

Best Regards !

Sorry my ignorance in electronics, but what would be the one wire wound

in item 3 ??

3) one wire wound power resistor 35 ohm / 25 - 50W .

Thanks

Last edited:

Hi FullRangeMan !

Wirewound resistor mean relative big power resistor which is made in the way that some resistive wire is wound around some ceramic body , and usually can stand relative higher power disipation .

Here is the picture with some typical examples , but wirewound resistors exist in many other physical forms too .

Best Regards !

Wirewound resistor mean relative big power resistor which is made in the way that some resistive wire is wound around some ceramic body , and usually can stand relative higher power disipation .

Here is the picture with some typical examples , but wirewound resistors exist in many other physical forms too .

Best Regards !

Attachments

Wow! they are big ones.Hi FullRangeMan !

Wirewound resistor mean relative big power resistor which is made in the way that some resistive wire is wound around some ceramic body , and usually can stand relative higher power disipation .

Here is the picture with some typical examples , but wirewound resistors exist in many other physical forms too .

Best Regards !

Thanks again you most kind.

I cant imagine would be this device.

Regards

6c33c warm up question

I usually warm up my 6c33c tubes by turning on only filament heaters (and bias ) for minimum 15 minutes before turning on B+. I find that the sound is best after playing modestly for another 10 mins.

Sometimes for convenience I turn on filaments and just leave them heating for an hour or more before firing up the b+ and listening to the amps.

Question - am I depleting tube life during the warm up period, or only while b+ is on?

I usually warm up my 6c33c tubes by turning on only filament heaters (and bias ) for minimum 15 minutes before turning on B+. I find that the sound is best after playing modestly for another 10 mins.

Sometimes for convenience I turn on filaments and just leave them heating for an hour or more before firing up the b+ and listening to the amps.

Question - am I depleting tube life during the warm up period, or only while b+ is on?

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Buying guideline for 6c33c