That is a big box.

The box only has to be big enough to create a tunnel that will allow the desired amount of airflow with a minimum of turbulence. Somewhere between 10 - 30 m/s will work, larger being better since it allows a lower velocity for a given amount of airflow.

I found a displacement calculator. Looks like an 18" might have something like .3ish cfm of displacement. I assume that means from one extreme to the other? So then at, say 18hz, thats about 5.4cfs. At 10hz, 3cfs.

You don't need a calculator. Displacement is Sd x xmax. Xmax is usually given as 1 way linear travel (not peak to peak) so in that case it would be Sd x (xmax x 2).

The blower I have is rated at 700cfm. Probably wide open, so lets say we have 500 to work with behind ducts and valves and baffle and whatnot. WAG. I have NO idea what this thing's static pressure curve looks like. I know it pushes quite a lot harder than a squirrel cage, speaking strictly of flow at higher static pressure. So that's 8.3cfs, regardless of frequency.

So by 20hz, I am not doing anything a single 18 couldn't, and spending a lot of trouble doing it. But down at 10hz, I am in the fight with 3 18s... to make noise I cant hear... great. 🙂

By 5hz, we would need 6 18s to keep up.

Definitely start to see why the woofer loses oomph fast as the frequency drops... And why the rotary woofer can maintain such a pretty flat response curve.

Yes, fan subwoofers become more efficient as frequency decreases, the polar opposite of moving coil driver subwoofers.

I don't think your blower is the right tool for the job simply due to the 3 inch exit. You want a fan with a large cross sectional area (large blades) so it can move the same amount of air at much lower velocity. Trying to force too much air through a small exit hole is going to create screaming loud turbulence noise.

I cant help feeling I am missing too many important variables for this to be very meaningful, but it doesn't seem completely crazy yet. Especially if the goal is a strictly infrasonic emitter.

But velocity. The thing absolutely roars air. It is powerful and intimidating. Big box outside the valve and I need a huge valve... no can flutter at 10hz without huge servos and rapidly wearing parts.... Big box inside the valve and I use up my theater with a hush box that might as well be a speaker box with a couple of 18s and an eq weighted heavily on infrasonics. Probably not a huge cost diff either way really, bit one way ends up with a Frankenstein bunch of ducts and wires and blowers. The other is an off the shelf speaker in a wood box.

All of this can be outside the listening room, it can even be outside your house if you want. It's a very simple system, just a fan inside a duct and a servo motor outside the duct. (2 wires and some ductwork.) It doesn't even have to be round duct, the only part that absolutely needs to be round is the part encasing the fan blades (assuming a regular fan is used and not a blower). The construction and wiring of the device is extremely simple.

The much harder part is the specifics of the servo motor. This is why my previous experiments didn't go anywhere. I couldn't even find prices for servo motors. I don't know how to spec a servo motor for the job. I don't even know what type of servo motor to use. I don't know how to control a servo motor with an audio amplifier. I don't know if I should run right off the motor shaft or use a gear.

Here's a couple of useful links for someone that knows what they are looking at.

http://www.drivetechinc.com/articles/pm96sizrev2.pdf

http://www.baldor.com/support/Literature/Load.ashx/BR1202-F?LitNumber=BR1202-F

I haven't got a clue and find it very hard to research because servo motor research is BORING.

If you can make any sense of servo motors I can help with the rest.

Last edited:

"Deadly sounds" my yass.

2 acoustic watts is 123 dB SPL.

37 Hz is not considered "infrasonic" this century.

Art

I've seen that link several times over the years. It's full of errors, misconceptions and misunderstandings. It sounds like it was written by a junior reporter that didn't really understand the subject matter.

The whole idea that they were getting sick for days at a time without feeling the source of the infra tones is ridiculous (without even knowing what was making them sick), it would have felt like a little earthquake if it had enough strength to make people bedridden with nausea and "internal tearing".

Last edited:

Heavy duty servo motors were common last century for controlling large tape drives.The much harder part is the specifics of the servo motor. This is why my previous experiments didn't go anywhere. I couldn't even find prices for servo motors. I don't know how to spec a servo motor for the job. I don't even know what type of servo motor to use. I don't know how to control a servo motor with an audio amplifier. I don't know if I should run right off the motor shaft or use a gear.

I haven't got a clue and find it very hard to research because servo motor research is BORING.

If you can make any sense of servo motors I can help with the rest.

They can be cheap as surplus, but now are far more expensive new than excellent woofers, the reason Danley has not used them since the Intersonics SDL (servo drive) series of speakers.

I really wish I could just edit instead of adding another post to correct this silly error.

Simple: Report your own post by hitting the red triangle on the left of that post and ask for it to be changed. Include your exact wording so we can copy and paste it.

The open edit system caused too many problems and too much work for the mods.

Simple: Report your own post by hitting the red triangle on the left of that post and ask for it to be changed. Include your exact wording so we can copy and paste it.

The open edit system caused too many problems and too much work for the mods.

I know that's available in case of emergency but I suspect you guys have better things to do than act as my personal secretary every time I make a stupid mistake. (It happens more often than I'd like and I really don't want to bother you.)

I'd like to see the edit time frame opened up to 1 or 2 hours though, that would take care of most issues.

Last edited:

Heavy duty servo motors were common last century for controlling large tape drives.

They can be cheap as surplus, but now are far more expensive new than excellent woofers, the reason Danley has not used them since the Intersonics SDL (servo drive) series of speakers.

I suspected the price would be outrageous, it usually is when no one lists prices.

If I was able to find one, how much torque do you think would be necessary? (Assuming a 12 or 18 inch vent size, up to 30 m/s airflow and a fairly heavy duty aluminum valve and pivot rod on decent bearings with a max. high end of 30 hz?)

The much harder part is the specifics of the servo motor.... If you can make any sense of servo motors I can help with the rest.

Now we are talking! The servos (stepper motors really) and the controller for converting an audio signal to a shaft position are my forte!

The part I don't really understand well is the acoustics. Box sizes and shapes, how much pressure do we really need? How much air movement? Will half the signal (pushing air in and just expecting it to leak out of the room before the next pulse instead of sucking it back out) get the feel we want, or will it just be awkward mechanical rumbling (or worse, just wind noise) that is decoupled from the audible bass and just makes no tactile sense? Etc...

... Then valving it with a servo and something like this: D690A1002 - Honeywell D690A1002 - 6" Single Blade Round Damper

From way back in post 1 ...

I think this damper is inadequate for this purpose. The diameter is too small to be useful (I'd do a minimum 12 or 18 inch diameter to ensure enough airflow at low velocity). And I concerned that the damper flat piece and the pivot rod might not be strong enough. Also, there are bearings (according to the description) but I don't think they are meant for the type of long term abuse this device would inflict. It's probably meant to flip 90 degrees once or twice a day, not 30 times a second.

I'm no expert on the mechanical side of things and it's hard to tell from such a small picture but this just doesn't look like the right part for the job.

Also, you need a dual path for the airflow at the valve, you can't just completely block the airflow.

Last edited:

Now we are talking! The servos (stepper motors really) and the controller for converting an audio signal to a shaft position are my forte!

The part I don't really understand well is the acoustics. Box sizes and shapes, how much pressure do we really need? How much air movement? Will half the signal (pushing air in and just expecting it to leak out of the room before the next pulse instead of sucking it back out) get the feel we want, or will it just be awkward mechanical rumbling (or worse, just wind noise) that is decoupled from the audible bass and just makes no tactile sense? Etc...

Tom used a very high velocity three phase blower (10 horsepower IIRC) through a venturi, the output was horn loaded with a huge horn. The venturi could be frequency modulated with a servo motor, but amplitude was dependent on air flow.

There was plenty of air flow.

Think in terms of a frequency modulated siren on steroids, rather than a conventional speaker.

The Thigpen would be more "High Fi" as the fan blades can modulate both frequency and volume, a servo driven valve only modulates frequency, the blower volume sets the sound pressure level.

The sonic boom simulator had the displacement equivalent of an 8 foot by 12 foot piston moving 18" peak to peak.

That is 144 cubic feet of displacement.

Compare that to the displacement of a BC18SW115, a long throw 18 (used in my Keystone tapped horn subs) which has 187.6 cubic inches Sd.

One of those rattled chainsaws and various other stuff off the shelves in my shop when I was doing sine wave excursion testing.

Tools hung on screws fell to the floor, depending on the frequency I tested at.

The sonic boom simulator would be approximately the equivalent to 1326 of those 18” speakers driven with about 2 million watts.

Here is some information in Tom Danley's own words, circa 1998:

“In my work developing transducers at Intersonics Inc, I have built

devices and systems to produce high sound levels at both ends of the

spectrum. One sonic boom simulator supplied to BBN could produce 163 dB

at 5 HZ (in a concrete bunker) and could remove windows and doors from

there frames and fixtures.

Another sonic boom simulator (3 way system called "speakers from hell"

on "beyond 2000" TV show) had the displacement of an 8 foot by 12 foot piston moving 18" peak to peak, the system could produce >132dB on the outside wall of an old house from 3HZ to 5KHZ.

This is about 2 lb pressure acoustic pressure per sq ft and with a sine

wave at 3 HZ, made the middle of the wall move 8-10 inches in and out

and "house parts" frequently would fall off (I thought we broke the

house at one point when there was a loud crash from the crawl space so

we stopped "teasing" the house with the oscillator).

In testing, I intentionally experienced many slow TEF sweeps from 28

down to 3 HZ at full intensity (cause I'm a bass sicko) with never the

need to change underwear. Certainly there was a strong feeling of relief

when it stopped but it had no other Ill effect. BTW at 3 HZ the

threshold of audibility is about 125 dB so at 132 dB 3 HZ IS audible! I

felt fairly safe exposing myself to this as I had found a very good book

on the subject called "Infrasound and Low Frequency Vibration" edited by

W. Tempest, published by Academic press."

At any rate, a blower powered sub is not going to satisfy you in terms of fidelity, unless you do it the way the Thigpen does, or find some other way to instantly control the air flow of a high volume blower.

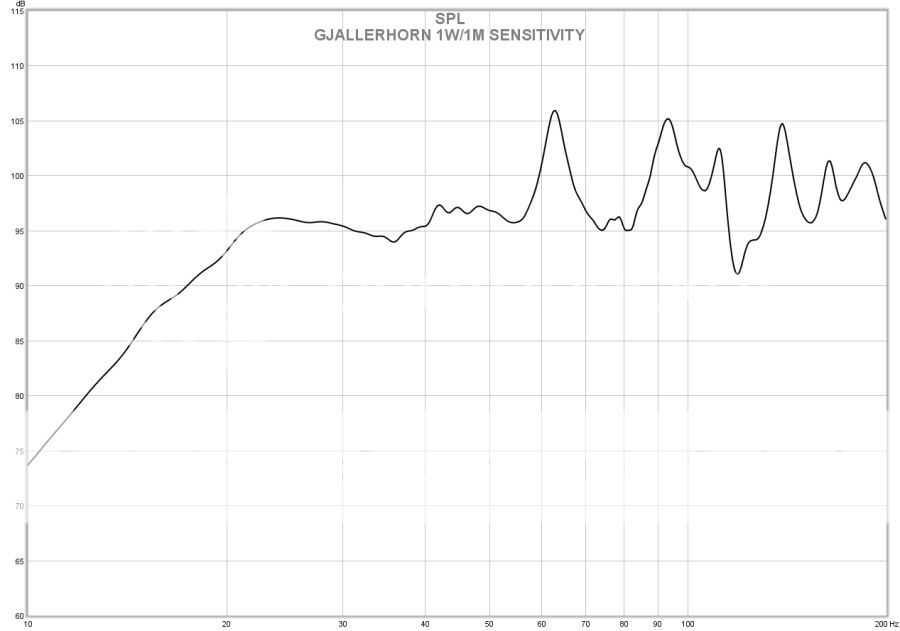

In which case, since you are not looking for output below 12 Hz, conventional higgh Xmax speakers will be far cheaper, whether one (or more) in a TH like Josh Ricci's Gjallerhorn, or several in an infinite baffle.

Personally, I would not want to hear VLF as loud as the Gjallerhorn can produce, the output of a pair of BC18SW115 playing 15 Hz laying open air on the shop floor to break in the suspension, probably only 105 dB, made me feel queasy after a few minutes, and the feeling persisted for another 15 or so.

Art

Last edited:

a servo driven valve only modulates frequency, the blower volume sets the sound pressure level.

That is an important point for sure, if it bears out.

I expected that modulating the frequency of the opening of a flap valve would modulate frequency, and modulating the degree to which it was opened would modulate amplitude. Again though, I am really weak on acoustics.

He mentioned '2lb/sf acoustic pressure', if that is just a relative air pressure measurement, this blower is rated at a max static pressure of about .25psi, or 36 lb/sf. Pressure is something we haven't really talked about yet, just volume, but it seems like we might still be in the ballpark with this blower.

That sonic boom generator is one noisy thing. I'd think something like 5% or 10% of it could be enough for a basement theater. .5 to 1 hp is right in the range of one of these blowers.

I didn't look too long, but what kind of a price are we talking for a Gjallerhorn? Obviously you'd have significant time or cost in cabinet work there.

Just a Guy, that valve was just a sort of example. I could build a 2sf opening box with a big flap on a sturdy shaft through a couple of bearings if it came to that. I cant help thinking it would be easier to valve right at the output of my blower and then put a big muffler on it. FAR less mass to flutter that way.

Another idea would be two slotted plates flat against each other, maybe even 3 or 4 square feet each, with matching slots that opened up a little under 50% of the surface area. Slide one of the plates perpendicular to the slots length the distance of one slot's width, and the whole plate seals. Much less velocity required of the valving system to get good high frequency response.

Another idea, is to think of Fog Horns. They use compressed air to produce a sine wave @ high SPL. I realise it's @ a fixed f dictated by the horn dimensions, but maybe it could be adapted in some way/s ?

*********

No, but back then they wouldn't have ever experienced Anything like it. If a setup similar to it could be made more powerful, & go Way down low, then that "might" be a candidate !

As above plus, it must have seemed quite frightening @ the time.

*********

Originally Posted by weltersys

37 Hz is not considered "infrasonic" this century.

No, but back then they wouldn't have ever experienced Anything like it. If a setup similar to it could be made more powerful, & go Way down low, then that "might" be a candidate !

Originally Posted by just a guy

I've seen that link several times over the years.

As above plus, it must have seemed quite frightening @ the time.

I think pneumatic fog horns were probably rotary sirens or huge reed whistles. Like pipe organ pipes, those can only produce oscillation on one frequency at a time though, so they cant really do what we want. As far as I know anyway.

I expected that modulating the frequency of the opening of a flap valve would modulate frequency, and modulating the degree to which it was opened would modulate amplitude. Again though, I am really weak on acoustics.

You are correct, air will always follow the path of least resistance. It's not all or nothing (full open or full closed), partially open or partially closed will send the air in different directions and the more it is opened or closed the more air it will deflect. I'm not sure it would be perfectly accurate (output tracking input with no variance) but it would work. And for sensitivity adjustability you could use a variable speed fan (low speed at night for quieter operation, high speed in the daytime for showing off and wrecking the house).

He mentioned '2lb/sf acoustic pressure', if that is just a relative air pressure measurement, this blower is rated at a max static pressure of about .25psi, or 36 lb/sf. Pressure is something we haven't really talked about yet, just volume, but it seems like we might still be in the ballpark with this blower.

I don't think it's important to start talking about pressure unless you want to compare directly to Danley's quote. I find it much simpler to talk in terms of velocity, displacement and cfm.

I can see that you are still attached to the blower idea. Here's a simple program that will show you pretty quickly why the blower isn't going to work.

Flare-it - Free Speaker Design Software

And a quick screenshot from the page.

The core velocity (red line) is the velocity in m/s you have to stay below in straight sections of pipe. The chuffing limit (blue line) is the velocity you need to stay below at boundary conditions. Boundary conditions are basically anywhere there is an abrupt change in cross sectional area, like at the exits. But this also applies to abrupt changes inside the line (there usually aren't any in a port but there will be inside this proposed device).

Exceeding the limits as shown by the blue and red lines is going to introduce turbulence and if you exceed them by a great amount there will be massive turbulence. There will be compression and rarefaction and problems similar to little tornadoes inside the line (at any areas with abrupt changes in csa) and at the exits. Turbulence is distortion, it's not something you can filter out with a fibreglass lined chamber. In a ported box this phenomenon is called port compression and it results in system losses and distortion. If the compression gets too high the port ceases to function as a port at all, it becomes completely blocked up like a sealed box.

There's only so much air you can put through a 3 inch pipe before creating massive problems that can't be fixed.

That sonic boom generator is one noisy thing. I'd think something like 5% or 10% of it could be enough for a basement theater. .5 to 1 hp is right in the range of one of these blowers.

I don't think it was ever intended to play music at low distortion. IIRC it was intended to artificially start avalanches (for pre-emptive avalanche safety) when the people responsible for that duty started to run out of old surplus artillery that they originally used for that purpose. As such, I don't think it makes much sense to try to directly compare your proposed device to Danley's, or try to match it in any way.

I didn't look too long, but what kind of a price are we talking for a Gjallerhorn? Obviously you'd have significant time or cost in cabinet work there.

It uses this driver:

TC Sounds LMS Ultra 5400 18" DVC Subwoofer 293-666

and probably 5 or 6 sheets of plywood, ideally baltic birch. And then whatever finish you want to use, Duratex is popular.

I don't particularly like the frequency response of the Gjallerhorn and you could probably do a lot more with that driver in a larger horn. It wouldn't be my first choice but it is loud and probably more than you really need unless you want strong response lower than 16 hz or so.

Lots of Gjallerhorn info here:

http://www.data-bass.com/data?page=system&id=45

Last edited:

As far as I know, Tom's sonic boom simulator does not modulate amplitude, only frequency.I expected that modulating the frequency of the opening of a flap valve would modulate frequency, and modulating the degree to which it was opened would modulate amplitude. Again though, I am really weak on acoustics.

I didn't look too long, but what kind of a price are we talking for a Gjallerhorn? Obviously you'd have significant time or cost in cabinet work there.

The Thigpen is an interesting approach, by varying both blade pitch and "wobble" the frequency and SPL level can be controlled, more aggressive pitch makes more air flow even though the fan sped is fixed.

I'm no HVAC expert, but it seems to me that if you try to choke off air flow to a blower as a "volume control", it will make farting noises.

If you are weak on acoustics, trying to design a modulated blower subwoofer will be quite a challenge, far exceeding the work of making any number of sub designs that are capable of high output down to 12 Hz.

The Gjallerhorn uses a very expensive LMS 18", around $1000, and at least 4 4x8 sheets of plywood as a guess.

It was designed for use in a very large room, overkill for small rooms if you are not looking to literally break your house.

I use a little Mackie HRS120 sub (a 12" and 12" passive radiator) in my studio control room, it only takes about 105 dB at around 15 Hz to make the drywall flap.

TH can put out 6-10 dB more LF than ported or sealed cabinets, so half the drivers and power are needed, but box size is larger.

Using a pair of Eminence Lab 12" (about $160 apiece) in a cabinet like the Danley DTS-10 you could get SPL levels around 20 dB louder than the HRS120 down to 10 Hz in a small room. There are several TH designs for the Lab 12", or the TC Epic 12", which has even more Xmax, but is more expensive.

The DTS-10 does not appear to be a difficult build, especially when compared to a blower driven sub 😉.

Attachments

Last edited:

I'm no HVAC expert, but it seems to me that if you try to choke off air flow to a blower as a "volume control", it will make farting noises.

Look at the pic I posted a couple pages ago. It's never choked. When it's fully closed in one direction it pulls air in from the other side.

You could use fan speed as a crude stepped volume control (low speed or high speed) but I don't see how that would cause farting noises either, it's always fully open to air supply on one side or the other. (During the course of a movie this setting wouldn't be changed, it would only be changed when you wanted a "loud" session or a "quieter" session.

In normal operation volume is controlled by the amount of deflection of the valve, very much like the rotary sub. That's not going to cause farting noises either (again, one side or the other is always fully open to an outside air supply) so I'm not sure what you are talking about.

It sounds like maybe you are talking about modulating the speed of the fan with the music signal, if so, of course that isn't going to work.

Last edited:

Although the blower arrangement could generate extreme levels, Tom developed the Matterhorn TH for a high fidelity approach to ridiculous amounts of VLF.Look at the pic I posted a couple pages ago. It's never choked. When it's fully closed in one direction it pulls air in from the other side.

In normal operation volume is controlled by the amount of deflection of the valve, very much like the rotary sub. That's not going to cause farting noises either (again, one side or the other is always fully open to an outside air supply) so I'm not sure what you are talking about.

The sonic boom generator is far simpler and far less costly per acoustic watt generated, but it was designed for making noise, not music.

... Tom developed the Matterhorn TH for a high fidelity approach to ridiculous amounts of VLF.

I think he developed the Matterhorn as a marketing stunt, despite the buzz about military application. I don't think he ever sold it to the military and I don't think the military ever used it. But it was a fantastic marketing tool.

Regardless, they are two different devices for two different purposes, they cover entirely different bandwidths (0 - 30 hz vs 15 - 100 hz). Each of them has several octaves of passband but those passbands only overlap for a single octave, so the Matterhorn is more different than similar. Danley doesn't try to get high output at single digit frequencies from moving coil drivers.

The sonic boom generator is far simpler and far less costly per acoustic watt generated, but it was designed for making noise, not music.

The fact that it was made for purposes other than critical listening doesn't mean it can't produce pleasant audible output. It might need a bit of modification to make it a bit more suitable for subwoofer use but it's surprisingly similar to the trw rotary subwoofer, it just has a different physical layout with parts in different places and a flowthrough duct that the rotary sub doesn't need to work properly.

I don't think there's any point to building something like this unless high output at less than 10 hz is absolutely necessary, but if that is a requirement this seems like a viable option even if it's not super high fidelity.

Last edited:

As far as I know, Tom's sonic boom simulator does not modulate amplitude, only frequency.

The Thigpen is an interesting approach, by varying both blade pitch and "wobble" the frequency and SPL level can be controlled, more aggressive pitch makes more air flow even though the fan sped is fixed.

The sonic boom generator is pretty much a thigpen but with blades stationary and air moving around it. Both does the same job.

SBG modulates velocity of the air in and out of the dipole horn.

Think of it as an amplitude modulation of a DC airflow to produce sound.

At the utmost position the device will suck air from the back and push it out the front, in the middle it will just recirculate the air inside itself, at the other utmost position it will such air from the front and eject it at the back.

Rotary Subwoofer noise

With a large enclosure (mine is 4' w x 4' h x 8' long and

plenty of insulation the fan noise is negligible.

Fan speed is constant but can be varied to match the

size of the room.

It's still exciting after 4 and half years!!!

With a large enclosure (mine is 4' w x 4' h x 8' long and

plenty of insulation the fan noise is negligible.

Fan speed is constant but can be varied to match the

size of the room.

It's still exciting after 4 and half years!!!

Attachments

I agree.I don't think there's any point to building something like this unless high output at less than 10 hz is absolutely necessary, but if that is a requirement this seems like a viable option even if it's not super high fidelity.

Mishaux has stated he is not looking for output below 10-12 Hz, the blower approach will require more expense and not work in the "chest feel region" that he wants, while TH, BR or IB all would.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Blower or compressed air powered infra sub?