Looking good as always Mal! Aluminium clad is interesting. I'll be interested to see what they look like!

How you been good I hope 🙂 ,lucky the mistakes don't show up well in the pic's 😉 .Looking good as always Mal! Aluminium clad is interesting. I'll be interested to see what they look like!

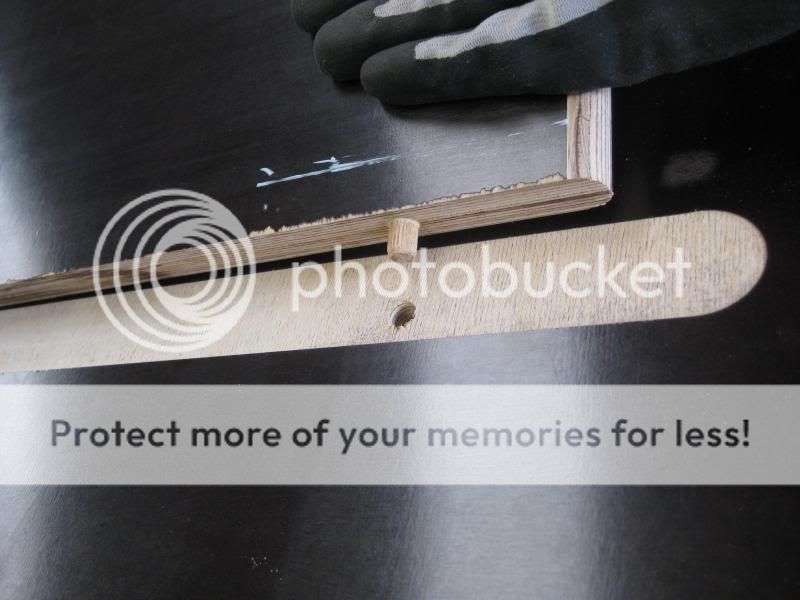

Home made roller ,with out the rolling bit 😀.

Cheers

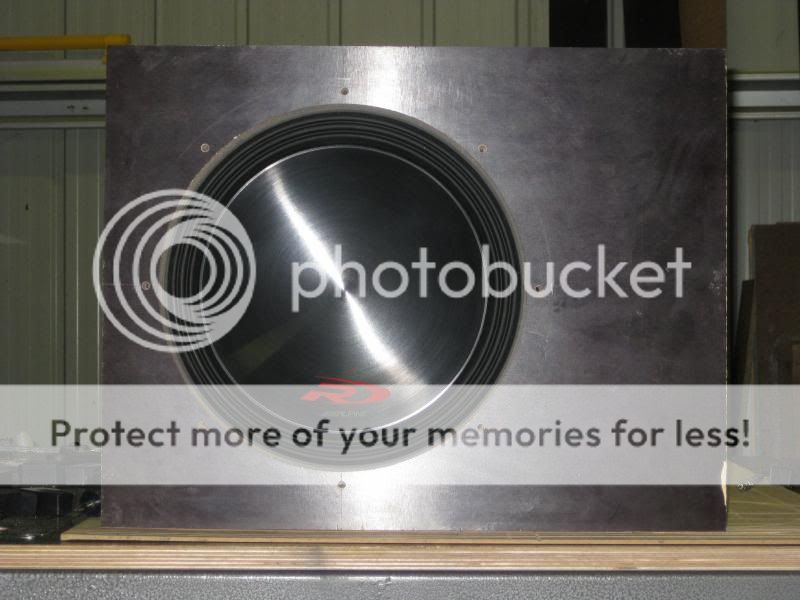

It fits

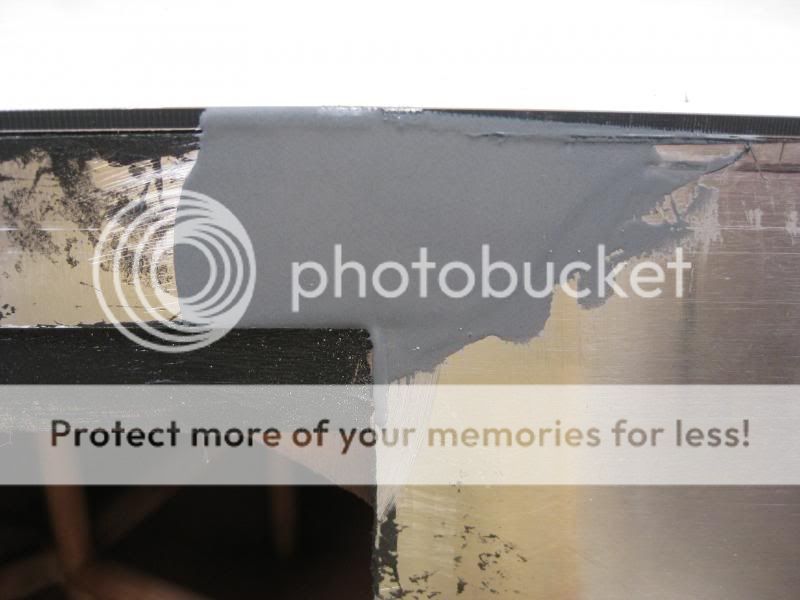

Bending it by hand has created a bit of a sweep/low after the bend ,but a couple coats of HiFill should correct the low .

Cheers

Bending it by hand has created a bit of a sweep/low after the bend ,but a couple coats of HiFill should correct the low .

An externally hosted image should be here but it was not working when we last tested it.

Cheers

bloody hell mal.

man, you had me hooked at the cross drilled dowels, this is even better.

Pity for late night listening you will end up painting it black, but till then!

man, you had me hooked at the cross drilled dowels, this is even better.

Pity for late night listening you will end up painting it black, but till then!

Pity for late night listening you will end up painting it black, but till then!

The only black will be the under coat 🙂 .

In 24 hours I'll see if they bonded 😱 .Looks like I have a nice 2mm layer of 11FC over the surface's . Might even get some dampening thrown in . I was able to get a couple tubes of Sika 252 ( for the baffles ) with out having to by a box of 12 .

Cheers

A nice piece of steel pipe would of worked better 🙂.For the tops and bottoms I'm going to cover them inReally looking good Mal! The best use of storm water pipe I've ever seen! Beautiful!

Aluminium composite sheets - Dilite | Geplast

A friend said you can curve it by routing the back out 75% so I'm going to try it and if it works I might cover the 2nd pair of cab's in it .Cheaper than 2014 grade alloy and larger sheets for less wastage .

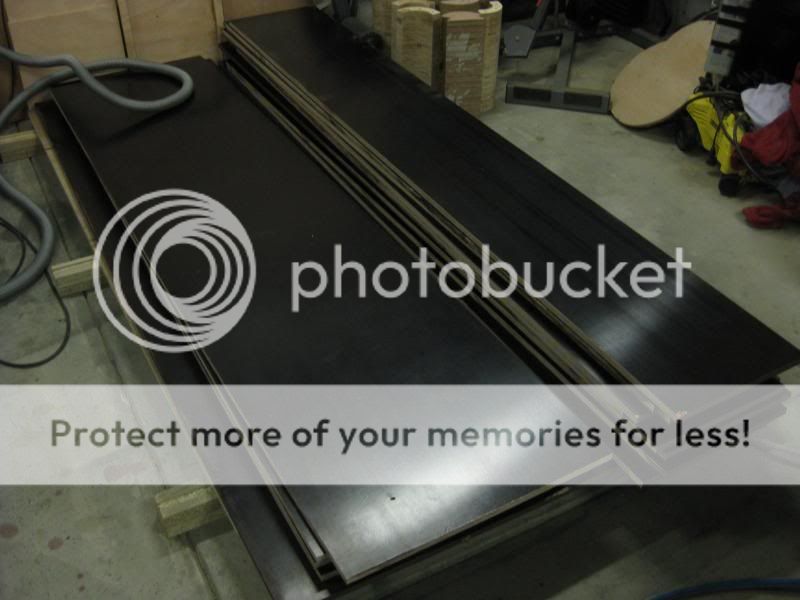

A mate came over so having the extra pair of hands we ripped down the sheet's for the tapped horns .Nothing worse than having to move full sheets around on your own .

CHeers

Love your work 56oval. Can't wait to see how they turn out.

Cheers mate

Today I bonded the top & bottoms on 🙂 . This time I cut the sausage and squeezed the 11FC on then used a wide blade scrapper to smooth it out and even ,this worked better than beading it on .

Cheers

I've used that aluminium composite before. A thicker version for building cladding. It's a very good idea! I've never used it to bend but I would think that your 75% is a good idea. Should give it a nice bend. Good luck with it Mal.

Linc

Linc

56Oval,

They're looking great, you're making some astounding progress of late, keep it up!!

I'm quite interested in seeing more of these tapped horns, will eventually be in touch with Paul to get him to give me a hand with some too.

Chris

They're looking great, you're making some astounding progress of late, keep it up!!

I'm quite interested in seeing more of these tapped horns, will eventually be in touch with Paul to get him to give me a hand with some too.

Chris

I've used that aluminium composite before. A thicker version for building cladding. It's a very good idea! I've never used it to bend but I would think that your 75% is a good idea. Should give it a nice bend. Good luck with it Mal.

Linc

56Oval,

They're looking great, you're making some astounding progress of late, keep it up!!

I'm quite interested in seeing more of these tapped horns, will eventually be in touch with Paul to get him to give me a hand with some too.

Chris

Linc I'll see how it bends soon 🙂.

Chris I'm going to finish the first pair of 15" cabs up to HiFill primer then put the tapped horns together . Once there together Paul wants to do a couple of in room measurements before they go in the roof .

Well the tig welding didn't go to good ,due to the heat transfer the Sikaflex kept on getting dragged into the weld joint 😡 . So good old liquid weld epoxy was used 🙂 .

Trimmed the alu-clad board next step, routing out the baffle area 😱 for a nice fit .

Cheers

Cheers

56Oval,

I'm quite interested in seeing more of these tapped horns, will eventually be in touch with Paul to get him to give me a hand with some too.

Chris

Even Chris

Pauls looking at selling his Rythmik sub drivers and amps .Might be worth getting because he already has the tapped horn design . Its a little bit smaller than mine .

Cheers

mal

SLowed Down to a crawl

After a week an a half the JB Weld epoxy cracked 😡 .

Out came the grinder and I removed the section and removed the Sikaflex behind the remaining allow .Thursday I'll mig weld new piece's in ,looking back I should of done this in the first place 🙄🙂.

I ended up routing out the baffle area .

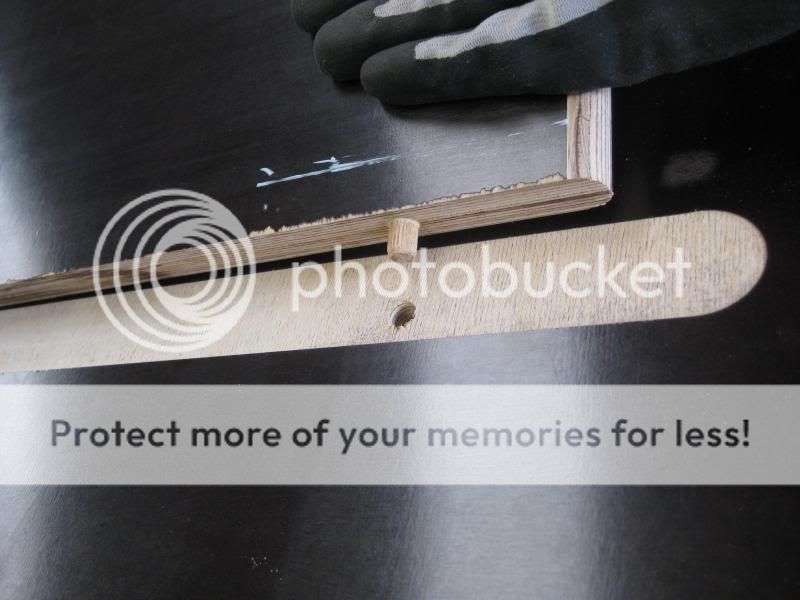

Held the jig in place with double sided tape

baffle fit , its tight so once I weld in the filler top & bottom panels I'll add an extra 1mm clearance .

I was a bit worried how good the BONDING of the Sika 11fc was . I had to use a Stanley knife and cut away while pulling the alloy piece off .

Cheers

After a week an a half the JB Weld epoxy cracked 😡 .

Out came the grinder and I removed the section and removed the Sikaflex behind the remaining allow .Thursday I'll mig weld new piece's in ,looking back I should of done this in the first place 🙄🙂.

I ended up routing out the baffle area .

Held the jig in place with double sided tape

baffle fit , its tight so once I weld in the filler top & bottom panels I'll add an extra 1mm clearance .

I was a bit worried how good the BONDING of the Sika 11fc was . I had to use a Stanley knife and cut away while pulling the alloy piece off .

Cheers

Last edited:

Looking good Mal! I've used those drivers before in my system a few years ago. They have some serious amounts of suspension travel!

HI Linc

Did you use the Alpines in your car system .

The bass cab's have been mig welded but in the mean time a mate has been giving me a hand putting the Tapped horns together .Ones almost finished waiting for glue to dry .

Dowelled the ends on the brace's and routered the removed the coating on the formply and aid in gluing .

CHeers

Did you use the Alpines in your car system .

The bass cab's have been mig welded but in the mean time a mate has been giving me a hand putting the Tapped horns together .Ones almost finished waiting for glue to dry .

Dowelled the ends on the brace's and routered the removed the coating on the formply and aid in gluing .

CHeers

I actually had a pair of the alpines as part of my original horn setup. They weren't horn loaded. Just in a sealed box under the horns. They play low and loud.

A bit of an update .Glued the end's and end brace in next gluing the top on .I'm going to power the TH's with a Crown XTi 2002 .

The wife asked if its going to be cut down to make a pair 😀 , I no and this is one of a pair 😱😀 . Next question was where are they going ,in the lounge room corners 🙂.

The BMS 4550 CD's have landed and I've ordered a pair of Celestion NTR21-5010 JD drivers for bass duties ,these will be partnered with an S3 Synergy horn . Whats one more project 😀

😀

Cheers

Mal

The wife asked if its going to be cut down to make a pair 😀 , I no and this is one of a pair 😱😀 . Next question was where are they going ,in the lounge room corners 🙂.

The BMS 4550 CD's have landed and I've ordered a pair of Celestion NTR21-5010 JD drivers for bass duties ,these will be partnered with an S3 Synergy horn . Whats one more project

😀

😀Cheers

Mal

hi Mal

let me know when you fire these things up so i know its not an earth quake shaking my house....

just your new speakers

Sheafer

let me know when you fire these things up so i know its not an earth quake shaking my house....

just your new speakers

Sheafer

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- 4 way active ,passive or what works best