hi all,

i was recently having a bit of a clean out at in the garage and came across a few items that spawned the above idea, 12x phillips pl500 sweep tubes (some 27v heater, some 12v heater), 10x hitachi 400v, 680uf capacitors and two transformers, one a 230 - 230 300va toriod and a 30va, 40v ei.

i have seen a guys video on youtube (i believe hes on this site somewhere) of his pl36 based otl

https://www.youtube.com/watch?v=ksBvKeN0u5o

i am looking to set these bits up i have as an integrated otl that has tone and balance adjustments all in the one unit, nothing is new on the preamp side of things,ill share the circuit i use for this later on....

im after a few opinions on how to go about this ....i have seen a couple of schematics using pl36 tubes in otl configuration and from what i read they are not too drastically different from the pl500 (i think the dissapation of a pl36 is 16w vs the pl500s 12w?)

so was thinking to follow this schematic....

http://bildarkiv.hififorum.nu/Lord/byggen/PL36_OTL.gif

i dont have any power goals, as i have no idea what this will net, however bare in mind there is enough room on the chassis for another 12 tubes and the power supply cap array is over the top even with 24 tubes! (not too sure about what HT current will be required for 12, let alone 24! however... a 100w + per channel otl amp would be great!

anyway, thanks for reading and any advice any of you gurus have would be great!

mike

i was recently having a bit of a clean out at in the garage and came across a few items that spawned the above idea, 12x phillips pl500 sweep tubes (some 27v heater, some 12v heater), 10x hitachi 400v, 680uf capacitors and two transformers, one a 230 - 230 300va toriod and a 30va, 40v ei.

An externally hosted image should be here but it was not working when we last tested it.

i have seen a guys video on youtube (i believe hes on this site somewhere) of his pl36 based otl

https://www.youtube.com/watch?v=ksBvKeN0u5o

i am looking to set these bits up i have as an integrated otl that has tone and balance adjustments all in the one unit, nothing is new on the preamp side of things,ill share the circuit i use for this later on....

im after a few opinions on how to go about this ....i have seen a couple of schematics using pl36 tubes in otl configuration and from what i read they are not too drastically different from the pl500 (i think the dissapation of a pl36 is 16w vs the pl500s 12w?)

so was thinking to follow this schematic....

http://bildarkiv.hififorum.nu/Lord/byggen/PL36_OTL.gif

i dont have any power goals, as i have no idea what this will net, however bare in mind there is enough room on the chassis for another 12 tubes and the power supply cap array is over the top even with 24 tubes! (not too sure about what HT current will be required for 12, let alone 24! however... a 100w + per channel otl amp would be great!

anyway, thanks for reading and any advice any of you gurus have would be great!

mike

Last edited:

Well,yes I think it could work.With some luck,depends on the condition of the PL500's,you have 500mA peak per tube.1A5 on 8ohm gives 9W sine,somewhat like you have to put in one PL500 heater :-( .

It woudn't be a bad idea also to have a speaker protection-circuit.If a tube shortens you get 300V on them.

Mona

It woudn't be a bad idea also to have a speaker protection-circuit.If a tube shortens you get 300V on them.

Mona

Hi mike , yes this is the related video of my PL36 OTL amp , if you are interested more information you can find here http://www.diyaudio.com/forums/tubes-valves/200823-my-new-circlotron-otl-tube-power-amp-2.html , as for the schematic that you posted , I think it will work , but in the 300V power supply you have to put an CLC filter to minimize hum , and if you can parallel the two sections of the 6N6P ( of course with the respective changes ) you will have better drive capabilities .hi all, ..... i have seen a guys video on youtube (i believe hes on this site somewhere) of his pl36 based otl

https://www.youtube.com/watch?v=ksBvKeN0u5o

i am looking to set these bits up i have as an integrated otl that has tone and balance adjustments all in the one unit, nothing is new on the preamp side of things,ill share the circuit i use for this later on....

mike

thank you both for the replies, dimitris, you may recall my comments on your youtube video, just want to say that you have inspired me to undertake this....

i am looking to use possibly a 12au7 in the phase inverter stage, as i have a few of these at home, any idea how they would manage driving 6 tubes?

i am looking to use possibly a 12au7 in the phase inverter stage, as i have a few of these at home, any idea how they would manage driving 6 tubes?

12x phillips pl500 sweep tubes (some 27v heater, some 12v heater)

mike

Aren't all PL500s 27V, 300mA heaters??

thank you both for the replies, dimitris, you may recall my comments on your youtube video, just want to say that you have inspired me to undertake this....

i am looking to use possibly a 12au7 in the phase inverter stage, as i have a few of these at home, any idea how they would manage driving 6 tubes?

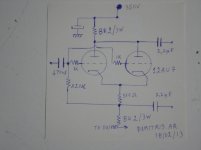

Yes I remember your kind words , and I am glad that my amp inspires you to start building your project , of course you can drive 6 PL36 with the 12AU7 tube , you have to parallel the two sections of the tube , I don't test it but it will work , sure it will not have the driving capabilities of 6N6P or ECC182 , but it will work quite good , the circuit is attached below .

In case you want more power and lower output impedance you will have to use another driver/spliter tube and you will need 10 or 12 PL36 or PL500 which is very similar to PL504 .

Attachments

Sure all PL500 are 300mA 27v .Aren't all PL500s 27V, 300mA heaters??

ok, after almost a years of dealing with life, im onto this project again, the 24x pl500 tubes have long since arrived and I have done much contemplating on the overall design, however I do need some more pointers from the OTL gods on this site as to what tubes to use in the first and second stage, so I can complete the autocad drawings....

im looking still for a good phase splitter circuit for this, I noticed dimitris you used two pcl type triode/pentode tubes per channel for this task in your newer project, if im correct in saying, you used the triodes as the input stage and the pentodes as the phase splitter?

to simplify things in the supply department, I have looked into using a large tv power supply isolating transformer (one per channel) that is 230v-230v, capable of delivering around 4 amps to run both the amplifier side and 12x 27v heaters in series (27x12=324v) (230v to DC =230 x 1.414=325v - will look into what the transformer actually spits out after losses before implementing it, though this may work out to be too higher voltage for the amplifier circuit, so may have to look into using a separate transformer after all, but using such high voltage for the heaters will keep the current and heat down as much as possible in the supply area)

any pointers here would be much appreciated!

mike

im looking still for a good phase splitter circuit for this, I noticed dimitris you used two pcl type triode/pentode tubes per channel for this task in your newer project, if im correct in saying, you used the triodes as the input stage and the pentodes as the phase splitter?

to simplify things in the supply department, I have looked into using a large tv power supply isolating transformer (one per channel) that is 230v-230v, capable of delivering around 4 amps to run both the amplifier side and 12x 27v heaters in series (27x12=324v) (230v to DC =230 x 1.414=325v - will look into what the transformer actually spits out after losses before implementing it, though this may work out to be too higher voltage for the amplifier circuit, so may have to look into using a separate transformer after all, but using such high voltage for the heaters will keep the current and heat down as much as possible in the supply area)

any pointers here would be much appreciated!

mike

Hi preludefan , as I remember you want to build a Futterman topology OTL amp , therefore my newer amp which is Circlotron topology does'n fit for your perpose , for your amp you can use tubes like ECC99 or ECC182 as cathodyne phase splitter and parallel the two triode sections for better driving capabilities , in my Futterman amp I use EL84 triode connected for this purpose .

As for the heater power supply of the PL500 , it's more safe to connect them in parallel , for example you can use a 27V ( about 70VA ) secondary winding for each 6 PL500 , this means that you will have four seperate 27V/ 70VA windings for the 4 rails ( 2 rail in each channel ) .

As for the heater power supply of the PL500 , it's more safe to connect them in parallel , for example you can use a 27V ( about 70VA ) secondary winding for each 6 PL500 , this means that you will have four seperate 27V/ 70VA windings for the 4 rails ( 2 rail in each channel ) .

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- pl500 based integrated OTL amplifier