Half the year in Vancouver, the other half in Kihei.If not, could someone tell me the best place to live,

As ethnically diverse as possible.the best food to eat

Talk to Jimmy Buffett.how to enjoy the ultimate lifestyle

Walk, bicycle or local transit where possible.where I can buy a perfect car/automobile

With a beautiful woman, a glass of fine red or dry ale and of course, a crimson sunset.all while listening to high-end audio?

Those ones were easy. This best core material, well, that's another story. 😉

Half the year in Vancouver, the other half in Kihei.

As ethnically diverse as possible.

Talk to Jimmy Buffett.

Walk, bicycle or local transit where possible.

With a beautiful woman, a glass of fine red or dry ale and of course, a crimson sunset.

Those ones were easy. This best core material, well, that's another story. 😉

--------

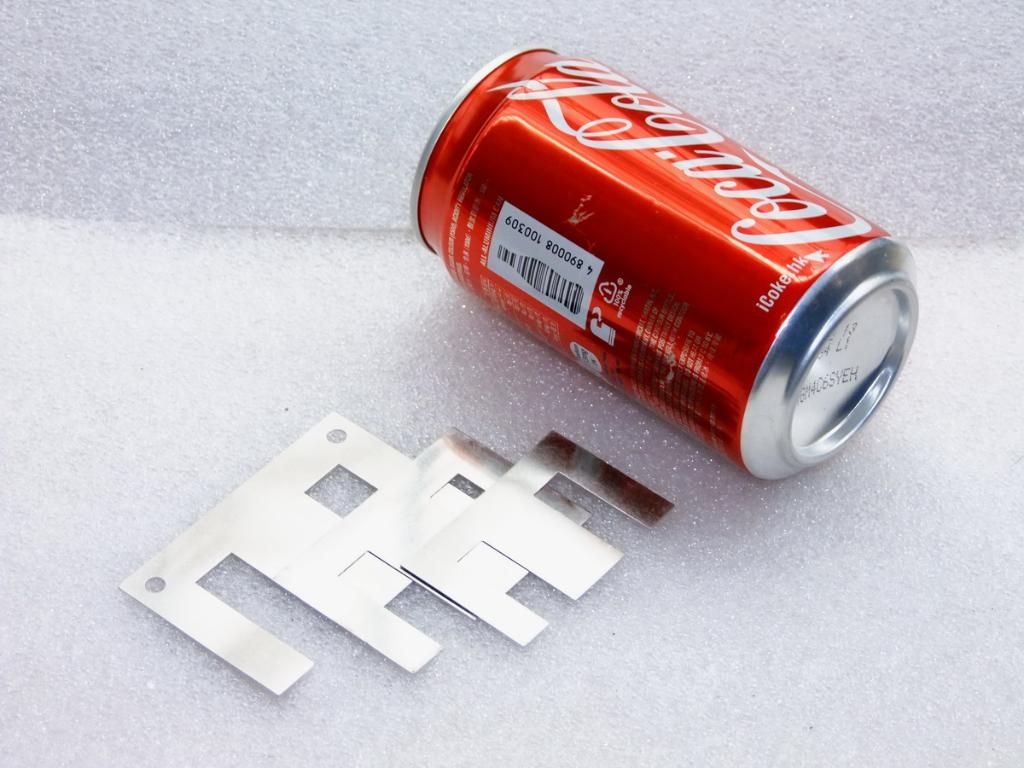

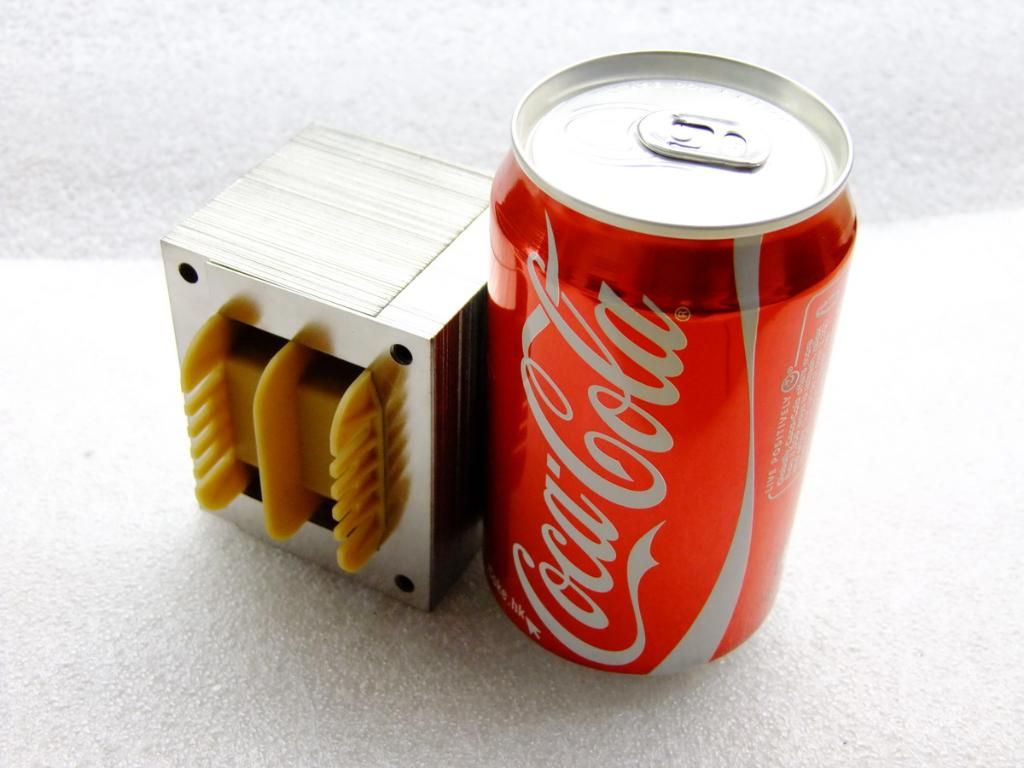

That's right. I only said my comment for it only. Also my test was use market famous permalloy OPT to comapre. For PP OPT I recently got this which prepare to test and comapre.

thx

TVC

Last edited:

Member

Joined 2009

Paid Member

--------

That's right. I only said my comment for it only. Also my test was use market famous permalloy OPT to comapre. For PP OPT I recently got this which prepare to test and comapre.

thx

TVC

I am interested in your impression of the Tango nickel push-pull transformer. So far the best OPT I've heard are the Slagle 80% nickel and the Tango NY-10.

John

I am interested in your impression of the Tango nickel push-pull transformer. So far the best OPT I've heard are the Slagle 80% nickel and the Tango NY-10.

John

Hi John,

NY-10? is it the same as model no. NY-10S,No.10429. 80% nickel core will very easy saturate, need increase core size to prevent core saturation in same power rating!😛

are U use of it, can I had a look of it. very interesting!!!

BTW, in my testing of different % nickel contain permalloy core, EI were 45~50% 0.25mm permalloy laminations. large size was EI 76.2, 96 and the largest was EI120 size. But there will had some double c-core coming was 78% 0.1mm thickness.

thx

TVC

Last edited:

TVC, what material are in your pics? they look like the silicon steel cores sold here, H50 i think is the grade, it is 0.5mm thick, how thick are those laminates?

hi tony,

this is not H50 laminations, 0.5mm thick H50 grade had serious core lose and looks only can use in lower grade power tx and will quite HOT during operate, probably in cold area will be OK but in Asia cannot.

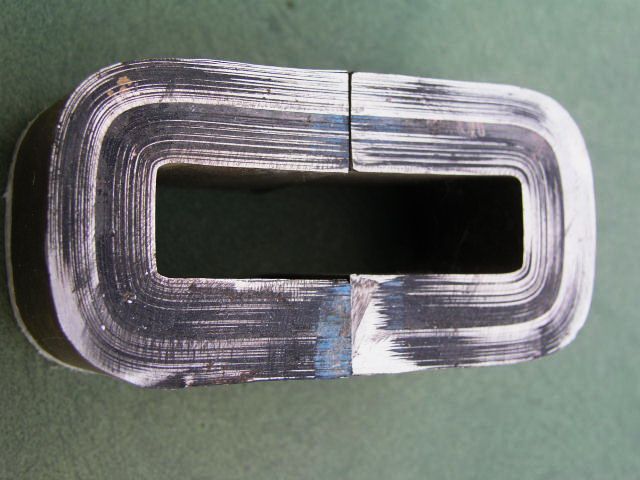

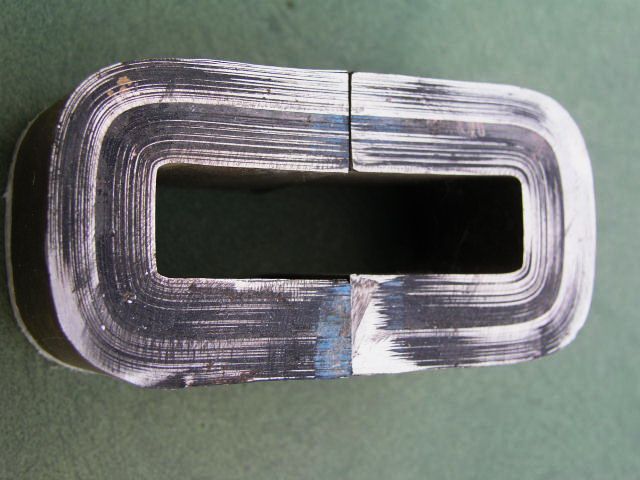

This is 0.25mm 45~50% nickel laminations( permalloy core) since cannot thinner regarding contain nickel in lamination will softer than normal silicon steel laminations(0.35MM Normally Hi-B).

There will had 0.1 mm double c-core, 78~80% nickel core coming to me.>50% nickel contain was super radio metal core. Regarding funishing of double c-core was rolling thin permalloy sheets together to its shape and cut. Thinner and softer sheets in higher Nickel hadn't any problem for the processes.

If compare the wave form of Tx which made by permalloy and silicon, the HF will better much more and less ringing form. Compare the sound for them can heard permalloy core will had less grained sound if compare to silicon steel. silicon steel also had its advantage, bass punch will better than permalloy and amorphous core.

Photos was some my stocks permalloy core around 45% Nickel contain but its size was not too large. Photos I taken longer time before so was not very good quality.

thx

this is not H50 laminations, 0.5mm thick H50 grade had serious core lose and looks only can use in lower grade power tx and will quite HOT during operate, probably in cold area will be OK but in Asia cannot.

This is 0.25mm 45~50% nickel laminations( permalloy core) since cannot thinner regarding contain nickel in lamination will softer than normal silicon steel laminations(0.35MM Normally Hi-B).

There will had 0.1 mm double c-core, 78~80% nickel core coming to me.>50% nickel contain was super radio metal core. Regarding funishing of double c-core was rolling thin permalloy sheets together to its shape and cut. Thinner and softer sheets in higher Nickel hadn't any problem for the processes.

If compare the wave form of Tx which made by permalloy and silicon, the HF will better much more and less ringing form. Compare the sound for them can heard permalloy core will had less grained sound if compare to silicon steel. silicon steel also had its advantage, bass punch will better than permalloy and amorphous core.

Photos was some my stocks permalloy core around 45% Nickel contain but its size was not too large. Photos I taken longer time before so was not very good quality.

thx

TVC,

do you get those c-cores in china or HK ?

do you have a website or address for the supplier of these materials ?

Thanks

do you get those c-cores in china or HK ?

do you have a website or address for the supplier of these materials ?

Thanks

in hong kong, U can contact Nippon steel.

We are a trading company affiliated with Nippon Steel Corporation in Japan. We are experienced in steel trading and our sales professionals help customers to choose the appropriate products. Thus, pursuing the creation of value-added distribution in the steel business.

Address: Suite 5, 23/F., Sino Plaza, 256-257 Gloucester Road, Causeway Bay, Hong Kong.

Contact: Mr. Patrick Wong

Phone No.: (852) 2506 1014

Other Phone No.: (852) 9108 3148

Fax No.: (852) 2506 2010

Homepage: www.yp.com.hk/nipponsteel

Other Homepage: www.nipponsteel.biz.com.hk

Email: nsh-n001@nshk-net.com.hk

----------------------------------------------

My amorphous was ask for hitach soft metal hk.

i Corporate Name Hitachi Metals Hong Kong Ltd.

Address Units2212-14, 22/F, Miramar Tower 132 Nathan Road Tsimshatsui, Kowloon, Hong Kong.

TEL +852-2724-4183

FAX +852-2311-2098

Founded 1987-10-1

Business Overview Manufacturing operation and marketing of soft ferrite core and its component products. And marketing of magnet products and speciality steel products.

More Information

“ú—§‹à‘®ƒAƒhƒ�ƒbƒgŠ”Ž®‰ïŽÐ

Map of corporate (Popup windows)

We are a trading company affiliated with Nippon Steel Corporation in Japan. We are experienced in steel trading and our sales professionals help customers to choose the appropriate products. Thus, pursuing the creation of value-added distribution in the steel business.

Address: Suite 5, 23/F., Sino Plaza, 256-257 Gloucester Road, Causeway Bay, Hong Kong.

Contact: Mr. Patrick Wong

Phone No.: (852) 2506 1014

Other Phone No.: (852) 9108 3148

Fax No.: (852) 2506 2010

Homepage: www.yp.com.hk/nipponsteel

Other Homepage: www.nipponsteel.biz.com.hk

Email: nsh-n001@nshk-net.com.hk

----------------------------------------------

My amorphous was ask for hitach soft metal hk.

i Corporate Name Hitachi Metals Hong Kong Ltd.

Address Units2212-14, 22/F, Miramar Tower 132 Nathan Road Tsimshatsui, Kowloon, Hong Kong.

TEL +852-2724-4183

FAX +852-2311-2098

Founded 1987-10-1

Business Overview Manufacturing operation and marketing of soft ferrite core and its component products. And marketing of magnet products and speciality steel products.

More Information

“ú—§‹à‘®ƒAƒhƒ�ƒbƒgŠ”Ž®‰ïŽÐ

Map of corporate (Popup windows)

OT: TVC, i once worked with a Patrick Wong from HongKong dealing with Micro Automation wafer saws, wonder if he could be the same person? i used to work for a big semiconductor assembly plant in Manila in the 80's...

Mmm, I'd say nanocrystalline (heat treated amorphous) cores. Low eddy currents, low hysteresis, low magnetostriction, permeability often comparable to mu-metal, and Bsat comparable to silicon steel.

AFAIK, there are only two manufacturers of amorphous/nanocrystalline products, Vacuumschmeltze and HMG (Hitachi). I've met with reps from both; VAC mostly makes toroids (best for common mode filtering and high frequency transformers), but they have a few cut cores as well. HMG makes both; AMCC- series cut cores are fairly easy to find. Prices are comparable, and as far as I know, so is performance.

This doesn't really matter for audio. Given the chance, I'd probably go with a high-nickel lamination or something like that, or at least GOSS, just because normal silicon steel sucks. I wouldn't consider amorphous, because the cost-to-benefit ratio is tiny compared to the better (and thinner) laminations. (The improvement just going from 16 or 10 mil SS lams, to 4 mil lams or strip, is larger than the improvement from NiFe to amorphous.)

Amorphous really is best suited to two things: common mode chokes (where its high, mostly resistive impedance, and the bandwidth of that, are better than high-mu ferrites), and very compact transformers in a narrow range of operation. From about 5kHz to 50kHz, losses are much higher than ferrite, but also much better than the finest steel strip available. With Bmax up to 1.5T (even derating it to 0.8 or 0.6T to reduce losses), the power density over ferrite is unmistakable. Above 50kHz or so, the amount of flux you can pump into the stuff before it melts is less than you get from ferrite, so that ferrite is preferred from 50kHz to a few MHz (at which point everything goes to powdered iron and resonant RF voodoo). Although amorphous has better magnetization properties than conventional materials (like steel), this isn't really its dominant asset, except in very demanding, low level or low loss applications, where it competes with very high-mu alloys like supermalloy.

Oh, and amorphous materials are available in "square loop" formulations, which combined with the high permeability, small hysteresis and relatively low losses, make excellent saturable reactors, mag amps, etc. This is not a "big" application these days, of course, but an awful lot of small cores are made for this purpose.

Tim

AFAIK, there are only two manufacturers of amorphous/nanocrystalline products, Vacuumschmeltze and HMG (Hitachi). I've met with reps from both; VAC mostly makes toroids (best for common mode filtering and high frequency transformers), but they have a few cut cores as well. HMG makes both; AMCC- series cut cores are fairly easy to find. Prices are comparable, and as far as I know, so is performance.

This doesn't really matter for audio. Given the chance, I'd probably go with a high-nickel lamination or something like that, or at least GOSS, just because normal silicon steel sucks. I wouldn't consider amorphous, because the cost-to-benefit ratio is tiny compared to the better (and thinner) laminations. (The improvement just going from 16 or 10 mil SS lams, to 4 mil lams or strip, is larger than the improvement from NiFe to amorphous.)

Amorphous really is best suited to two things: common mode chokes (where its high, mostly resistive impedance, and the bandwidth of that, are better than high-mu ferrites), and very compact transformers in a narrow range of operation. From about 5kHz to 50kHz, losses are much higher than ferrite, but also much better than the finest steel strip available. With Bmax up to 1.5T (even derating it to 0.8 or 0.6T to reduce losses), the power density over ferrite is unmistakable. Above 50kHz or so, the amount of flux you can pump into the stuff before it melts is less than you get from ferrite, so that ferrite is preferred from 50kHz to a few MHz (at which point everything goes to powdered iron and resonant RF voodoo). Although amorphous has better magnetization properties than conventional materials (like steel), this isn't really its dominant asset, except in very demanding, low level or low loss applications, where it competes with very high-mu alloys like supermalloy.

Oh, and amorphous materials are available in "square loop" formulations, which combined with the high permeability, small hysteresis and relatively low losses, make excellent saturable reactors, mag amps, etc. This is not a "big" application these days, of course, but an awful lot of small cores are made for this purpose.

Tim

Last edited:

OT: TVC, i once worked with a Patrick Wong from HongKong dealing with Micro Automation wafer saws, wonder if he could be the same person? i used to work for a big semiconductor assembly plant in Manila in the 80's...

Hi tong,

since Patrick is a very common name in hong kong, I am not sure is it a same person. But, Nippon steel was a multinational corporation. Their employed staff most had experience relationship and background, so there also had chance be a same person. Can U let me little more information about him with U work in Manila, let me ask for hi next time when I meet him. 😀

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- Ultimate emotion core material ( types of silicon steel , Permalloy or Amorphous etc)