Has anyone tried increasing the open area spacing perforated steel to 79/80%. I would imagine this is may be less desirable than the 51% suggested.

I have been using 18 Gauge, 9/64" Holes on 3/16" Centers, Staggered Pattern,

51% Open Area, for a considerable time now. It would be nice to build my next panels using the honey comb looking perf 16 gauge steel mainly because it would look much nicer, but I don't know if it would cause a substantial loss in sound quality in comparison from the 3/16 hole size 51% open area, to that of 1/4" hole size 70% open area utilizing a .062 spacing/ 1.6mm.

Thanks,

Doc

I have been using 18 Gauge, 9/64" Holes on 3/16" Centers, Staggered Pattern,

51% Open Area, for a considerable time now. It would be nice to build my next panels using the honey comb looking perf 16 gauge steel mainly because it would look much nicer, but I don't know if it would cause a substantial loss in sound quality in comparison from the 3/16 hole size 51% open area, to that of 1/4" hole size 70% open area utilizing a .062 spacing/ 1.6mm.

Thanks,

Doc

Has anyone tried increasing the open area spacing perforated steel to 79/80%. I would imagine this is may be less desirable than the 51% suggested.

...I don't know if it would cause a substantial loss in sound quality...

I'm not sure about the difference in sound quality, but you will probably loose 2db - 3dB in output based on tests results posted here:

http://www.diyaudio.com/forums/planars-exotics/183168-acoustat-answer-man-here-8.html#post2494150

Thanks Bolserst, I don't think 2-3db will be that significant. I thought that with the reduced amount of metal there would be a decrease in the electrostatic field from the stators.

That was the idea that originally led me to use a wire mesh, besides cost.

I was going to use some 1/8" spacing wire mesh but I never got any and now it is very hard to source,But some 1/4 stuff can be had at the hardware store and I plan on giving it a try some time.

There may be a bit of loss but I think that it can be compensated for by using higher voltages, maybe.

I believe we had a discussion on this a while back and there was some one whom has used it and posted pictures of their panels and they did look very nice.

I believe that they did say that there was a bit of drop in sensitivity.

It is to bad that a higher open area with smaller holes is not really available.

Stuff that has been mentioned can be had but at a cost and it is not a common material usually.

FWIW

jer 🙂

I was going to use some 1/8" spacing wire mesh but I never got any and now it is very hard to source,But some 1/4 stuff can be had at the hardware store and I plan on giving it a try some time.

There may be a bit of loss but I think that it can be compensated for by using higher voltages, maybe.

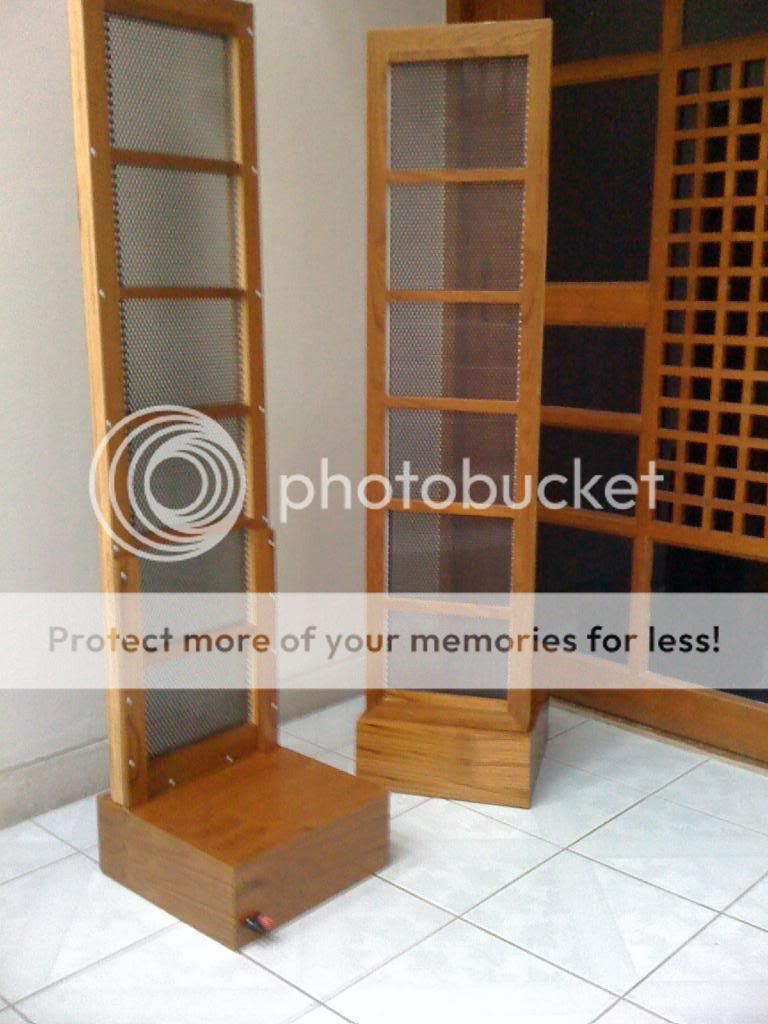

I believe we had a discussion on this a while back and there was some one whom has used it and posted pictures of their panels and they did look very nice.

I believe that they did say that there was a bit of drop in sensitivity.

It is to bad that a higher open area with smaller holes is not really available.

Stuff that has been mentioned can be had but at a cost and it is not a common material usually.

FWIW

jer 🙂

I've tried it before.

To me, I like them very much. The sound is more open to my ears. However, they are not so strong, and you will need to make some reinforcement.

Wachara C.

To me, I like them very much. The sound is more open to my ears. However, they are not so strong, and you will need to make some reinforcement.

Wachara C.

I thought it was you Wachara.

It has been a while since that discussion.

Thanks for chiming in!!!

Cheers!!

jer 🙂

It has been a while since that discussion.

Thanks for chiming in!!!

Cheers!!

jer 🙂

Yeah, that's the image I thought I saw at some point! I agree the slight loss can be compensated by increasing the voltage variably....That is why I keep waffling...LOL

BTW..I found that in 16 gauge, do you think it may be a pain to work with, or too flimsy?

I am looking for a perforated sheet that is more visibly and perhaps audibly transparent.

Thanks gentlemen for you input, it is always very

helpful!!!

BTW..I found that in 16 gauge, do you think it may be a pain to work with, or too flimsy?

I am looking for a perforated sheet that is more visibly and perhaps audibly transparent.

Thanks gentlemen for you input, it is always very

helpful!!!

Thanks for the pic an post.....more open has to sound better...but less output...means more bias...

what would the SPL be?

what would the SPL be?

...more open has to sound better...but less output...means more bias...

There certainly are conflicting design issues.

One more thing to consider, when you use stators with particularly large open areas(>75%?) the diaphragm will no longer be driven with uniform force over the whole area. The areas in the middle of the stator hole openings will not be driven with nearly as much force as the areas around the stator holes. I don't know what affect this may have on sound quality, as I haven't done the comparison. Just something to consider...

I was thinking about that last night,And I am wondering if setting the stators with the holes off center or misaligned might help that a bit?

As opposed to the holes lined up at least there would be more force on one side of the holes and the effect would be distributed evenly between the two sides.

jer 🙂

As opposed to the holes lined up at least there would be more force on one side of the holes and the effect would be distributed evenly between the two sides.

jer 🙂

I was thinking about that last night,And I am wondering if setting the stators with the holes off center or misaligned might help that a bit?

It certainly seems logical that staggering the stators would smooth out drive force on the diaphragm.

Test results posted here for aligned vs staggered stators shows that you don't be lose SPL one way or the other.

So, averaging of the force over the diaphragm area with staggered stators is a logical conclusion.

http://www.diyaudio.com/forums/plan...-more-questions-els-design-3.html#post2772574

The downside of staggering of course is loss in optical transparency.

Decisions, decisions....

Looking at the quad 57 mid/ tweeter arangement you have way less open area and both are offset significantly....go figure

Regards

David

Regards

David

All good points, I must admit there is a proportional degree in the increase of the WAF (Wife Acceptance Factor) to the increase in visual and optical transparency. I must admit I too prefer that look.

....Ultimately this was the reason for the inquiry, I believed that the increase in open area would decrease the amount of metal necessary to move the diaphragm however, I am using a 6um film which likely takes 1/2 the force compared to the 12um to stretch. I would guess that it may take less energy to move, but would require greater bias power to increase sensitivity...?

....Ultimately this was the reason for the inquiry, I believed that the increase in open area would decrease the amount of metal necessary to move the diaphragm however, I am using a 6um film which likely takes 1/2 the force compared to the 12um to stretch. I would guess that it may take less energy to move, but would require greater bias power to increase sensitivity...?

Yes,Bolserst I do remember that discussion,Only the dimensions were not included.

If memory serve me right It was determined that the hole size under a certain dimension made little difference in performance, but open area certainly does effect how it sounds.

But when the hole size increases significantly to effect performance then a second look at the theory of staggered vs Non-staggered may be in order.

Just a few thoughts.

jer 🙂

If memory serve me right It was determined that the hole size under a certain dimension made little difference in performance, but open area certainly does effect how it sounds.

But when the hole size increases significantly to effect performance then a second look at the theory of staggered vs Non-staggered may be in order.

Just a few thoughts.

jer 🙂

While a more open stator looks transparent which is pleasing I believe it is the wrong way to go for performance. I would imagine that around 30% open perhaps even a little lower (27%) would be about optimum. Greater air load is what I think is needed. Best regards Moray James.

Very interesting James, This almost seems counter intuitive as it would appear that with a reduction of air between the diaphragm and stator would decrease sound output. I am currently using 51% open area and I couldn't imagine it could sound any better by increasing or decreasing open area.

smaller open area more load due to increased resistance. From 27 -33% open are is probably about right. Lowest open area I built was about 35%. Easy enough to test. Diaphragm to stator spacing would not change. Best regards Moray James.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Increase ESL perforated panels hole size...???