Again, this disqualifies your point.My point is, that based on our listening tests Cryo treatment does not make the sound better, but worse.

If *you* believe this cryogenic magic had bring any change to the electrical characteristics of the wires you where listening to, and those modification had a negative effect on defects of the system you where listening to, how can you affirm those changes will not have an opposite (positive) effects on an other system ?

It makes no sens. As well as so many people witch affirm exactly the contrary.

You where talking about "generalizations" ?

Again, electrical components had "no sound", no taste. They have characteristics (we can measure for a large part) witch modifies the electrical transmission of alternative electric signals.

Last edited:

Hi,

Yet Douglas Self measures changes in the distortion behaviour of Capacitors with time (improvements). So maybe the middle age magic is in those who will see devils and demons wher ethere are simple observations and facts?

Actually, unless you buy the really ****** cheap chinese made stuff where not only the copper content is way less than what is stamped on the jacket (like 0.7mm^2 when it is supposed to be 1mm^2) and probably does not use the kind of copper specified for electrical systems, your standard solid core or stranded mains cable at your local building market is normally standardised as Oxygen Free Copper. So I guess the people who make electrical cables also are subject to "mediveial magic".

Teflon, or more precisely fluropolymers as insulation for cables are used in a wide range of applications outside audio. One really good thing about using it is the long terms chemical stability. The fact that it has low dielectric absorption for a plastic cannot harm, but is unlikely to be material in speaker cables. The fact that wire is normally silver plated before using fluoropolymer insulation MAY (or may not) have some impact though.

It is interesting to look at what cryogenics do in fields outside audio. Various temperature treatments (heat/cold) can alter the crystal structure in metals. It used on quite industrial scales for many reasons.

Yet they apply in terms of RFI sensitivity. But like all the other facts, if we only apply some medivieal magic and utter trice "devil pass from me" they just go away and can be ignored.

You should perhaps look at the magnitude of SOME of these effects and then compare your what small changes you claim make a big difference in your speaker crossover, with all the hundreds of trials and so on.

May I suggest that you in fact in one specific area, where you hold a belief that there is a difference strain at a gnat (in other words attempt to adjust for differences most would put past audibility) yet in other areas wher eyour hold a belief that it cannot make a difference, you gulp down the camel, whole and raw. This is a natural reaction for someone who has strong beliefs, however it does not aid any reality or realism in the issues.

So I think we part company here, you follow your religion, while I shall continue to look at reality.

Ciao T

PS, I do not specifically promote anything here, other than some open-mindedness.

We can see all the middle age magics in those audiophiles stupidities.

Burn-in, because people had noticed their cars run smoother afer a burn-in period. What the correlation between polishing mechanic and electricity ?

Yet Douglas Self measures changes in the distortion behaviour of Capacitors with time (improvements). So maybe the middle age magic is in those who will see devils and demons wher ethere are simple observations and facts?

Oxygen free because people dreams of purity and absolute ? My oxygen free cable looks like a little oxyded after a while -)

Actually, unless you buy the really ****** cheap chinese made stuff where not only the copper content is way less than what is stamped on the jacket (like 0.7mm^2 when it is supposed to be 1mm^2) and probably does not use the kind of copper specified for electrical systems, your standard solid core or stranded mains cable at your local building market is normally standardised as Oxygen Free Copper. So I guess the people who make electrical cables also are subject to "mediveial magic".

Teflon because this very 'magical' plastic was, a long time, a big secret of American army ?

(Fakes still carry on with his "cancer " dangerousness for your cooking equipments.)

Teflon, or more precisely fluropolymers as insulation for cables are used in a wide range of applications outside audio. One really good thing about using it is the long terms chemical stability. The fact that it has low dielectric absorption for a plastic cannot harm, but is unlikely to be material in speaker cables. The fact that wire is normally silver plated before using fluoropolymer insulation MAY (or may not) have some impact though.

Cryogenic treatments because people has read, here or there, some vulgarization papers about hyper conductivity ?

What else ?

It is interesting to look at what cryogenics do in fields outside audio. Various temperature treatments (heat/cold) can alter the crystal structure in metals. It used on quite industrial scales for many reasons.

All the hf conductivity characteristics of wires, witch does not apply at our frequencies tensions and currents,

Yet they apply in terms of RFI sensitivity. But like all the other facts, if we only apply some medivieal magic and utter trice "devil pass from me" they just go away and can be ignored.

Litz cables, skin effects, dielectric factors, electron migration from a wire to an other, variation of R with heat, nothing we are in concern with

You should perhaps look at the magnitude of SOME of these effects and then compare your what small changes you claim make a big difference in your speaker crossover, with all the hundreds of trials and so on.

May I suggest that you in fact in one specific area, where you hold a belief that there is a difference strain at a gnat (in other words attempt to adjust for differences most would put past audibility) yet in other areas wher eyour hold a belief that it cannot make a difference, you gulp down the camel, whole and raw. This is a natural reaction for someone who has strong beliefs, however it does not aid any reality or realism in the issues.

So I think we part company here, you follow your religion, while I shall continue to look at reality.

Ciao T

PS, I do not specifically promote anything here, other than some open-mindedness.

It is interesting to look at what cryogenics do in fields outside audio. Various temperature treatments (heat/cold) can alter the crystal structure in metals. It used on quite industrial scales for many reasons.

Besides the well-characterized martensite transition, are there any other DOCUMENTED examples (i.e., with substantiated claims)?

Sy,

I promised not to get drawn into any arguments with you and I will stick to this, at least for the time I promised...

Ciao T

Besides the well-characterized martensite transition, are there any other DOCUMENTED examples (i.e., with substantiated claims)?

I promised not to get drawn into any arguments with you and I will stick to this, at least for the time I promised...

Ciao T

....On the subject of cryogenic treatment of wire......,..snip.... ""We are unable to determine, by any tests that we are aware of, that a copper specimen has been subjected to a cryogenic environment"".

Whatta marroon...that John guy sounds like a real jerk.😱

He probably meant to say...by any "electrical" tests..

Folks,

Just a reminder.

My point is, that based on our listening tests Cryo treatment does not make the sound better, but worse.

Aw, heck. That's easy to explain.

Ya killed the plastics and the bonding between the metals and plastics. The expansion coefficients between the metals and the insulators typically shears the bonds.

If you subjected that ribbon construct to 4.5 kelvin, or even LN2, you probably cracked the gum rubber insulation all to heck, it's probably a powder...

Measure the inductance and capacitance before and after cryo. Maybe you'll see the electrical difference.

Cheers, jn

Last edited:

Sy,

I promised not to get drawn into any arguments with you and I will stick to this, at least for the time I promised...

Ciao T

Not interested in an argument. I neither agreed nor disagreed, I am looking for some explanation of your assertion.

Joachim,

This underscores my point that Amplifiers, Cables and Speakers should be seen as a system and designed in ways that make sure things work together. .........

Ciao T

This statement should be plastered all over every contentious thread on this site, in large letters in every retail shop and - especially - in every measurement lab/workshop/designer's workplace. 😉 [The statement requires the addition of the source equipment]

One of my first experiences of listening to a modest system assembled and put together [with this in mind and] at a moderate cost was astounding. It was a demonstration of excellence in giving deep musical satisfaction. But the guy who did this was Peter Quatrop way back when he had a shop in Highclere in the UK, well before he was involved with Audio Note.

Like all of us I have also heard cost no object systems to which I would not give house room - but which I would have loved to attempt to sort out....with re-orientating - room treatment - cable changes - decent racking/shelving/stands etc.

What changes and for what capacitors ? Electrolitics ? Some are better after a while, some worse, depends a lot of where they are made. Others ? Ceramics ? Polypro ? Most of them or does not vary with time, or get worse. What is a "distortion behavior" of a capacitor ? L ? R ? C error ? Arcs near their V limits ? Anyway,a good system does not use so much capacitors in the signal path (mine is 1, polypro)Yet Douglas Self measures changes in the distortion behaviour of Capacitors with time (improvements). So maybe the middle age magic is in those who will see devils and demons wher ethere are simple observations and facts?

Hum. It makes a difference in the good balance of half the energy of the all band (my cutting frequency is 1000hz) i can measure but not appreciate with my eyes (fletcher and Munson curves ?) and some edge phenomenas around 1 or more Mhz. Or i cant even measure. And, as i said previously, i do not fear my ears with such your assurance.You should perhaps look at the magnitude of SOME of these effects and then compare your what small changes you claim make a big difference in your speaker crossover, with all the hundreds of trials and so on.

Don't you never return to a mix after lunch and realize everything was bad, (effect of habituation) ?

About reality,well, that a long story between us and God.

Does you mean that some put the all finished cable in liquid helium/hydrogen ? I prefer not to look at the solders;-)Ya killed the plastics

Its affraying ...I believed they treat only the coper before to build the isolation around.

Hi,

Possibly. There where those electron microscope pictures of the two different metals (treated/untreated). I believe (but remember, this is something like near 15 Years ago) only the metal was treated and then assembled into cables. The cables where incidentally not using copper and where of the "Allen Wright DIY Speaker Cable" type (bare silver foil with PTFE wrap)...

Ciao T

Aw, heck. That's easy to explain.

Ya killed the plastics and the bonding between the metals and plastics.

Possibly. There where those electron microscope pictures of the two different metals (treated/untreated). I believe (but remember, this is something like near 15 Years ago) only the metal was treated and then assembled into cables. The cables where incidentally not using copper and where of the "Allen Wright DIY Speaker Cable" type (bare silver foil with PTFE wrap)...

Ciao T

Last edited:

Hi,

It does indeed require the addition of the rest of the system, however that route is considered off topic by some... 🙂

Ciao T

This statement should be plastered all over every contentious thread on this site, in large letters in every retail shop and - especially - in every measurement lab/workshop/designer's workplace. 😉 [The statement requires the addition of the source equipment]

It does indeed require the addition of the rest of the system, however that route is considered off topic by some... 🙂

Ciao T

Hi,

Read the latest issue of Linearaudio...

The way I formally was thought recording was to apply minimal, only absolutely essential adjustments (hence my quick disagreement with production values in the west), so to be honest, no... ;-)

I generally tried to avoid to have to fix things in the mix and tried to get the actual recording right. I know this is not a done thing these days...

I am unsure where G*d comes into this...

Ciao T

What changes and for what capacitors ?

Read the latest issue of Linearaudio...

Don't you never return to a mix after lunch and realize everything was bad, (effect of habituation) ?

The way I formally was thought recording was to apply minimal, only absolutely essential adjustments (hence my quick disagreement with production values in the west), so to be honest, no... ;-)

I generally tried to avoid to have to fix things in the mix and tried to get the actual recording right. I know this is not a done thing these days...

About reality,well, that a long story between us and God.

I am unsure where G*d comes into this...

Ciao T

I am unsure where G*d comes into this...

I can explain it, without any involvement of religions.

Impact of mind on random processes is known scientific truth, lots of studies confirm that.

Does you mean that some put the all finished cable in liquid helium/hydrogen ? I prefer not to look at the solders;-)

Its affraying ...I believed they treat only the coper before to build the isolation around.

No Liquid hydrogen. Extreme danger will robinson!!!

Liquid helium and nitrogen. I used both, but I believe standard cryo is nitrogen...it's cheaper than beer.

Solders aren't too bad through nitrogen or helium temps. Tin/lead solders work well, but the superconducting guys don't like it for connecting superconductors together..the lead can be a little superconductive below 10 kelvin, and that will impact the current density uniformity in the joints. Tin/silver is the preferred solder for superconductors because there is no superconductivity phase, and the tin/silver system is a stronger alloy. And interestingly enough, tin/silver eutectic or near eutectic does not pest.

Plastics are another story. There is a reason the NEC sets limits on the bend radius for wires. Taken cryogenic, many stressed plastics will crack. Same with outlets, plastic cases, whatever...I cannot recommend cryo treating any device which would be used in a National Electric Code covered application. It scares me.

Hi,

Possibly. There where those electron microscope pictures of the two different metals (treated/untreated). I believe (but remember, this is something like near 15 Years ago) only the metal was treated and then assembled into cables. The cables where incidentally not using copper and where of the "Allen Wright DIY Speaker Cable" type (bare silver foil with PTFE wrap)...

Ciao T

Ah, ok..metals treated first from both y'all.. I still contend after all these years, that there are no electrical changes in the metals..I've not seen any.

Cheers, John

Last edited:

Hi,

I did not measure the cables, only listened to them. According to the measurements that where taken RLC where all within "experimental error"...

Ciao T

Ah, ok..metals treated first from both y'all.. I still contend after all these years, that there are no electrical changes in the metals..I've not seen any.

I did not measure the cables, only listened to them. According to the measurements that where taken RLC where all within "experimental error"...

Ciao T

Hi,

I did not measure the cables, only listened to them. According to the measurements that where taken RLC where all within "experimental error"...

Ciao T

For capacitance, everybody seems capable of good measurements. For inductance, there are many ways the measurement can be compromised.

Within experimental error is an interesting thing to say without data to support it.

When I make a cable that I intend to use for listening tests, the second thing I do is measure the cable very accurately. Typically, I'll sweep it as far as the meters will allow with accuracy.

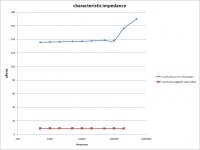

Here is one example..the hf anomoly in this case was the transmission of energy, the inductance of the separated conductors was ill behaved at 100 Khz and up.

I cannot understand a set of comparison tests with no supporting data.

Cheers, jn

Attachments

Last edited:

Hi,

I repeat, I did not carry out or organise the experiment, I merely participated.

Ciao T

I cannot understand a set of comparison tests with no supporting data.

I repeat, I did not carry out or organise the experiment, I merely participated.

Ciao T

cryo chages

we used differential cryo to shrink fit EF Au/Cu waveguides into brass blocks for Schottky detectors about the late '60's thru late '70's (to phrase it in curl'esque precision😀🙄) ... worked great and made quite a difference in the machining of high precision parts (talking fractional micron tolerances here)😉🙂

John L.

Besides the well-characterized martensite transition, are there any other DOCUMENTED examples (i.e., with substantiated claims)?

we used differential cryo to shrink fit EF Au/Cu waveguides into brass blocks for Schottky detectors about the late '60's thru late '70's (to phrase it in curl'esque precision😀🙄) ... worked great and made quite a difference in the machining of high precision parts (talking fractional micron tolerances here)😉🙂

John L.

I accused you of neither.Hi,

I repeat, I did not carry out or organise the experiment, I merely participated.

Ciao T

I merely pointed out my consternation at the lack of rigor involved with respect to actual testing and reporting of the electrical characteristics of the wires being compared.

jn

we used differential cryo to shrink fit EF Au/Cu waveguides into brass blocks for Schottky detectors about the late '60's thru late '70's (to phrase it in curl'esque precision😀🙄) ... worked great and made quite a difference in the machining of high precision parts (talking fractional micron tolerances here)😉🙂

John L.

That's sorta different than the cryotreatments I was talking about (which are claimed to alter and improve all sorts of things), but nonetheless interesting.

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- speaker cable myths and facts