Hi Art,

"The cabinet was built after many iterations with Hornresp."

I figured as much, same about bracing. I was just trying to help with a drawing that could get somebody started. It would help if you could post the sketch from Post #49 with a little better resolution. But anyway, if somebody wants to build it, there is more than enough information in this thread.

Regards,

"The cabinet was built after many iterations with Hornresp."

I figured as much, same about bracing. I was just trying to help with a drawing that could get somebody started. It would help if you could post the sketch from Post #49 with a little better resolution. But anyway, if somebody wants to build it, there is more than enough information in this thread.

Regards,

Hi 60ndown,

Looks to me the PA460-8 is more suited to a front loaded horn.

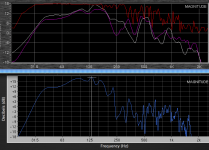

I'll attach what it would look like v. the 18SW115 in my quicky Hornresp model of my incorrect drawing of Art's sub without taking into account the Keystone exit (bold line PA460). In other words YMMV considerably.

Regards,

Looks to me the PA460-8 is more suited to a front loaded horn.

I'll attach what it would look like v. the 18SW115 in my quicky Hornresp model of my incorrect drawing of Art's sub without taking into account the Keystone exit (bold line PA460). In other words YMMV considerably.

Regards,

Attachments

Of course, once I tried to fold the horn, the iterations became more limited, due to the cabinet shape I committed to.Hi Art,

"The cabinet was built after many iterations with Hornresp."

I figured as much, same about bracing. I was just trying to help with a drawing that could get somebody started. It would help if you could post the sketch from Post #49 with a little better resolution. But anyway, if somebody wants to build it, there is more than enough information in this thread.

Regards,

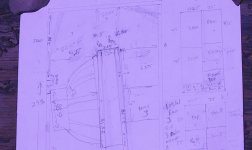

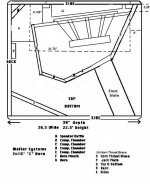

Here are three pictures, the full plan, the top half, and the bottom half.

There are no corner ramps, they were tested, did no good, were not used, though they look only partially erased on my sketch.

The sketch is pretty close to scale, though could use a keystone correction due to the angle I took the photo at to avoid glare.

Art Welter

Attachments

Hi Art,

If somebody can't get it from that, he is just not trying. Thanks for posting in higher resolution.

Regards,

If somebody can't get it from that, he is just not trying. Thanks for posting in higher resolution.

Regards,

way kool Art

btw - speaking of a keystone opening, here's a passive radiator 10" driver sub done some time ago by a Karlson builder

- since the highs aren't needed to be scattered, the starting gap can be increased

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

btw - speaking of a keystone opening, here's a passive radiator 10" driver sub done some time ago by a Karlson builder

- since the highs aren't needed to be scattered, the starting gap can be increased

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

Hi,

Just to add to my answer to 60ndown's question in Post #56: I put the PA460-8 into Hornresp, and it models fine as a front loaded horn, or an offset driver horn. It'll take about 380L_net, so it would be a bit larger than the Keystone.

Regards,

Just to add to my answer to 60ndown's question in Post #56: I put the PA460-8 into Hornresp, and it models fine as a front loaded horn, or an offset driver horn. It'll take about 380L_net, so it would be a bit larger than the Keystone.

Regards,

Attachments

Art, I have a few questions;

-Did you try corner correction in the first corner (S3 related)?

-What is the total weight of this cab?

(Oliver don't forget the metric world😉)

-Did you try corner correction in the first corner (S3 related)?

-What is the total weight of this cab?

(Oliver don't forget the metric world😉)

Last edited:

Not sure what you mean by corner correction.Art, I have a few questions;

-Did you try corner correction in the first corner (S3 related)?

-What is the total weight of this cab?

(Oliver don't forget the metric world😉)

I tried ramps in the upper right and left, and bottom left at the end of the horn, none of them had more positive impact than negative, so none were used.

I used a so called birch plywood, which seems to have only a birch veneer and some lighter weight filler wood, perhaps pine or Arunco. The cabinet is a lot lighter than Baltic birch, loaded with the Neo 18, I'd estimate about 150 pounds, 68 Kilos, a few pounds more than me.

The feet on the cabinet are made of plywood disks, the cabinet will "walk around" on a smooth floor at high power levels. I use a 45 x 45 inch plinth with receptacle holes under the stack to prevent movement, and provide stability for the 3 meter tall monolith.

The pair have cut at least 100 pounds from my overweight trailer from the four Lab 2x12 ported cabinets they replace.

The Keystone is light enough that I have "bear hugged" it and walked with it rather than take the time to retrieve my two wheel hand cart from the equipment trailer to move it.

Baltic Birch would no doubt be stiffer (and a lot heavier) but the cab seems tight and non-resonant with as much power as I have had available to throw at it.

Art Welter

Hi Art,

I know today everybody is clamoring for 22mm baltic birch (or some such), but once upon a time even Klipsch build his corner horns from simple 1/2" plywood. It also seems to work just fine in jbell's SS15. I wouldn't be surprised, if it wouldn't work for a Keystone sub too with a little added bracing. Just a thought.

Regards,

I know today everybody is clamoring for 22mm baltic birch (or some such), but once upon a time even Klipsch build his corner horns from simple 1/2" plywood. It also seems to work just fine in jbell's SS15. I wouldn't be surprised, if it wouldn't work for a Keystone sub too with a little added bracing. Just a thought.

Regards,

Thanks Art, you seem to have achieved very nice figures with that non baltic... I was already playing with some panel-flexing and some panel resonances and I think Oliver suggestion for improving the braces does seem to benefit the design. Although 1/2inch panels in a little small Oliver for 18" with an 16mm Xvar and much bigger surfaces than the SS15 with a 15inch 9.6mm driver 😉

With corner correction I meant something like your ‘ramps’ only for the first 180 degree bend to improve upper band response and some THD. Most probably it won’t harm your LF but I can imagine the LF response suffers from the other corner ‘ramps’.

With corner correction I meant something like your ‘ramps’ only for the first 180 degree bend to improve upper band response and some THD. Most probably it won’t harm your LF but I can imagine the LF response suffers from the other corner ‘ramps’.

Last edited:

IIRC, Jim said he could see something like 3/8" deflection on the SS15 at high power, and also noted he didn't mind the sound it made with over 100% distortion.Hi Art,

I know today everybody is clamoring for 22mm baltic birch (or some such), but once upon a time even Klipsch build his corner horns from simple 1/2" plywood. It also seems to work just fine in jbell's SS15. I wouldn't be surprised, if it wouldn't work for a Keystone sub too with a little added bracing. Just a thought.

Regards,

I don't like floppy cabinets, or endless bracing. The Keystone out of 3/4" seems comparatively light to me, even with Baltic birch I would not reduce the thickness, unless using only 100 watts or so.

I roll a stack of five 50 pound top cabinets up the ramp, the 150 pound Keystone is the lightest thing in my trailer from a size to weight ratio, other than a plastic tub of tarps.

Hi Art,

"...I roll a stack of five 50 pound top cabinets up the ramp..."

Now I remember why I got an "honest" job some 30 years ago. 🙂

Regards,

"...I roll a stack of five 50 pound top cabinets up the ramp..."

Now I remember why I got an "honest" job some 30 years ago. 🙂

Regards,

It would be wonderful if the response was as flat as a bass reflex cabinet and still had the 6 dB sensitivity advantage, but I'm satisfied with the frequency response compared to other horn and TH cabinets. Too late for me to try first corner ramps, but judging by what I found with the other ramps I would not expect much of an improvement, more of a switching one bump for another dip..With corner correction I meant something like your ‘ramps’ only for the first 180 degree bend to improve upper band response and some THD. Most probably it won’t harm your LF but I can imagine the LF response suffers from the other corner ‘ramps’.

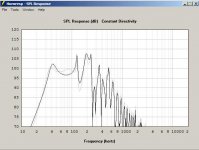

The upper chart has DSL's TH-118 in white, TH-115 in purple.

As far as I know, the basic cabinet layout is virtually identical, so you can see the difference the speakers make.

The Keystone is the lower chart, in blue.

The 165 Hz "jog" in the response shows up with the speaker in a BR, to a lesser degree.

With a bit of parametric equalization, it flattens right out, and the rest of the stuff is far enough out of band with a 100 Hz crossover point to not really matter.

Art Welter

Attachments

Hi,

Just to add to my answer to 60ndown's question in Post #56: I put the PA460-8 into Hornresp, and it models fine as a front loaded horn, or an offset driver horn. It'll take about 380L_net, so it would be a bit larger than the Keystone.

Regards,

cool thanks,

a bit larger is kinda vague, are we talking 3% larger or 12% or 30%?

if i add 2 inches to every dimension ill be close? 🙂

Hi,

Keystone sub looks like about 336 L_net in Hornresp. I'll try to look at it some more tonight.

Regards,

Keystone sub looks like about 336 L_net in Hornresp. I'll try to look at it some more tonight.

Regards,

An offset horn is not the same as the Keystone tapped horn at all, you will need to lay out an entirely different cabinet.no need, about 8% i make it, ill add a couple inches somewhere 😀

This is an example of an offset horn (I have a pair built in 2003 loaded with EVX-150A for sale if you'd like ;^)

Attachments

An offset horn is not the same as the Keystone tapped horn at all, you will need to lay out an entirely different cabinet.

This is an example of an offset horn (I have a pair built in 2003 loaded with EVX-150A for sale if you'd like ;^)

tempting, but ive seen some of your testing methods 😀

for now im going to build a quick and dirty version of your keyhole design, using the sketches i can see in this thread.ill be scaling it for an 8" subwoofer i have laying around.( have 2 different 8"s, ill try both in the box)

it likely wont be a good representation of the design, but if it produces something that I recognize as *special*,

I may be inspired to spend some money on a "real speaker"

Last edited:

hi Oliver - I'd like to see what an Eminence Sigma would do in Art's Keystone (besides burnup at high levels) -60Ndown - dunno if linear scaling will cut it - you might do some guesstimates with Hornresp - Best, Freddy

Good luck with that.tempting, but ive seen some of your testing methods 😀

for now im going to build a quick and dirty version of your keyhole design, using the sketches i can see in this thread.ill be scaling it for an 8" subwoofer i have laying around.( have 2 different 8"s, ill try both in the box)

it likely wont be a good representation of the design, but if it produces something that I recognize as *special*,

I may be inspired to spend some money on a "real speaker"

Scaling a regular horn down will mostly just raise FC.

Scaling a TH down will raise FC and may ruin the response entirely.

I would suggest building the design as the plan shows, and make an "O" adapter to try the speaker (s) you have laying around in it until you can afford a "real speaker".

Otherwise you will probably end up (if you are lucky) with another 80 Fb box like your quad Karlson.

- Home

- Loudspeakers

- Subwoofers

- Keystone Sub Using 18, 15, & 12 Inch Speakers