Upon receiving my EL70 drivers from Bob I cut two batches of wood. The first was for the Thirlmere dual driver single mouth MBVR. I tried those and at first was not impressed. As time went on and the drivers broke in a bit (and I got better at placing them) they sounded significantly better.

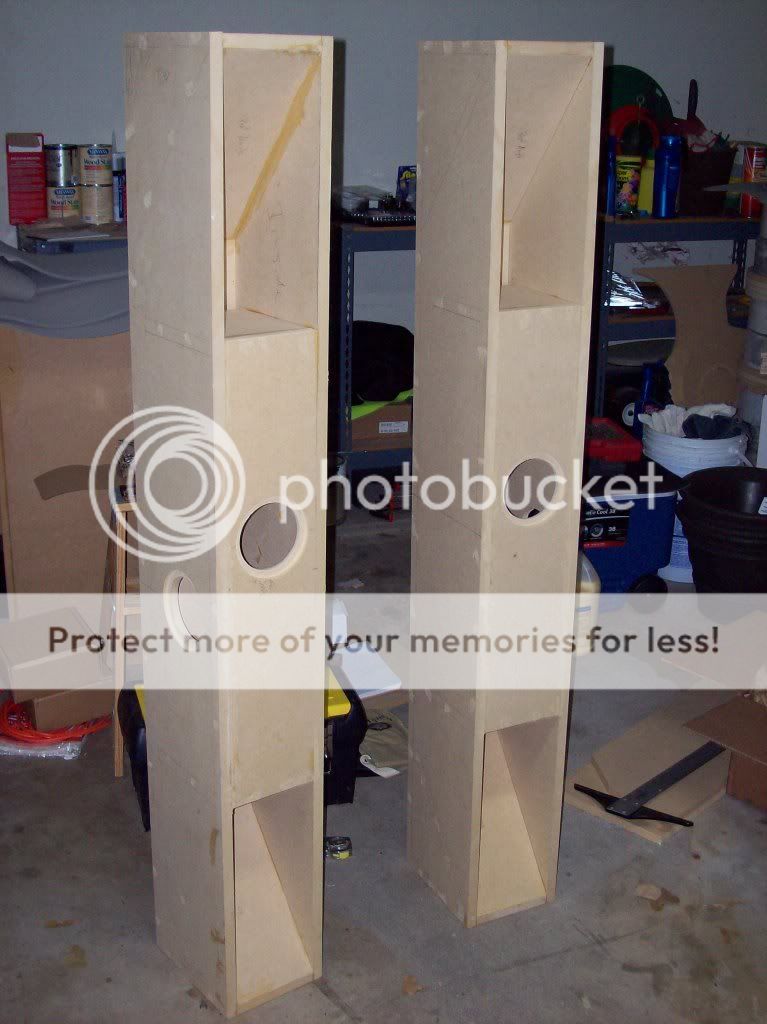

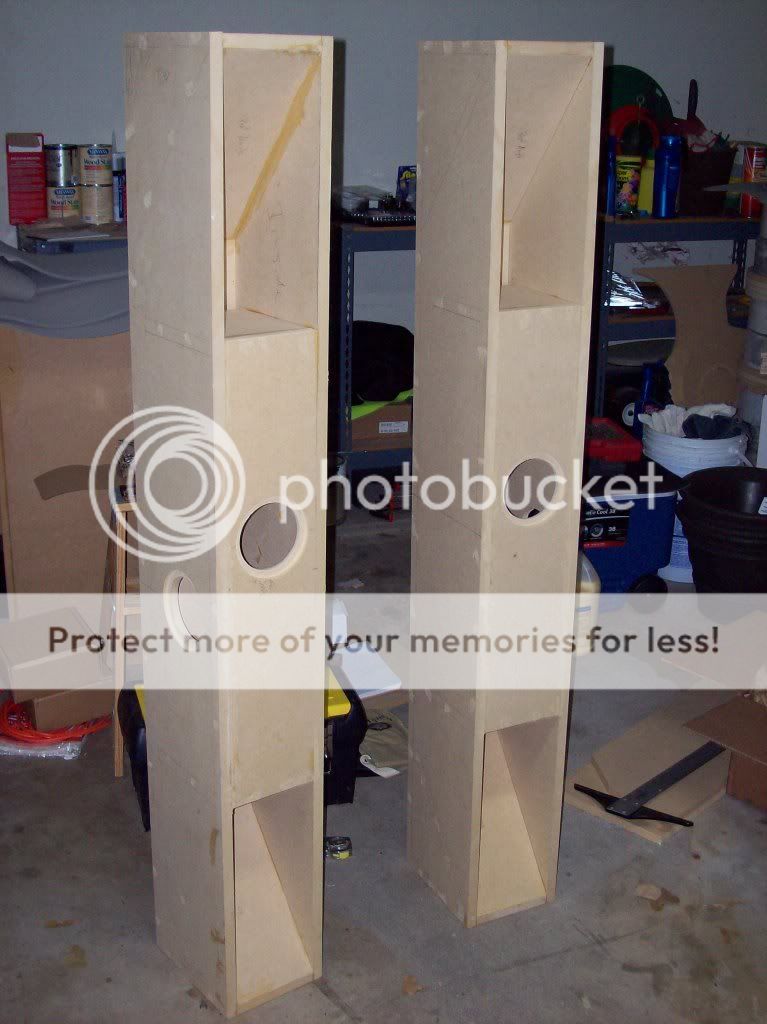

Since that time I've had a very full schedule of things to do and I'd forgotten about the second pile of wood I'd cut in my garage. This wood was intended to become a pair of Coniston^2 MBVR speakers...(pdf plans from Dave's site below)

http://homepage.mac.com/planet10/CSS/EL70/Lake-District-maps-080909.pdf

I'll document the build process for these as best I can with the appropriate pictures throughout. Now that I've gotten the motivation to start things should move quickly since I don't like leaving things unfinished.

I'm expecting great things out of these. The Coniston^2 design is very similar to the Lotus^2 that I favor so much so I'm anticipating results that are also similar. The Lotus^2 speakers were happy in a variety of listening environments and didn't depend on placement quite as much as the Thirlmere set did so I'm a bit excited about how this will play out with the new set.

I know there is at least one person here who will give me crap for using MDF but it has it's benefits in my particular case. If I'm going to stain the cabinets I use birch. If I'm going to paint them I use MDF since it has a much finer/smoother finish at the termination points and is very easy to work with.

That's all for now; pictures to come soon! 😀

Since that time I've had a very full schedule of things to do and I'd forgotten about the second pile of wood I'd cut in my garage. This wood was intended to become a pair of Coniston^2 MBVR speakers...(pdf plans from Dave's site below)

http://homepage.mac.com/planet10/CSS/EL70/Lake-District-maps-080909.pdf

I'll document the build process for these as best I can with the appropriate pictures throughout. Now that I've gotten the motivation to start things should move quickly since I don't like leaving things unfinished.

I'm expecting great things out of these. The Coniston^2 design is very similar to the Lotus^2 that I favor so much so I'm anticipating results that are also similar. The Lotus^2 speakers were happy in a variety of listening environments and didn't depend on placement quite as much as the Thirlmere set did so I'm a bit excited about how this will play out with the new set.

I know there is at least one person here who will give me crap for using MDF but it has it's benefits in my particular case. If I'm going to stain the cabinets I use birch. If I'm going to paint them I use MDF since it has a much finer/smoother finish at the termination points and is very easy to work with.

That's all for now; pictures to come soon! 😀

I know there is at least one person here who will give me crap for using MDF but it has it's benefits in my particular case. If I'm going to stain the cabinets I use birch. If I'm going to paint them I use MDF since it has a much finer/smoother finish at the termination points and is very easy to work with.

Might as well get it over with.... you said you had found a source for good ply... you better have had those panels cut before you said that 🙂

You should build something out od each and swap em in and out for a while.

dave

Might as well get it over with.... you said you had found a source for good ply... you better have had those panels cut before you said that 🙂

You should build something out od each and swap em in and out for a while.

dave

Yeah, I cut this wood about 3 months ago. That's how bad I've been slacking! Really though, if you've tried to paint birch ply with a smooth finish it's tough it's less continuous than MDF so it's a little annoying when you get to the painting stage.

I'm planning to do a build with the Mark Audio Alpair 12's next using birch ply but that's for another thread and another day.

Really though, if you've tried to paint birch ply with a smooth finish it's tough it's less continuous than MDF so it's a little annoying when you get to the painting stage.

Chris (i'm not allowed to build boxes anymore) is of the opinion it is easier to veneer than paint... MDF or ply

dave

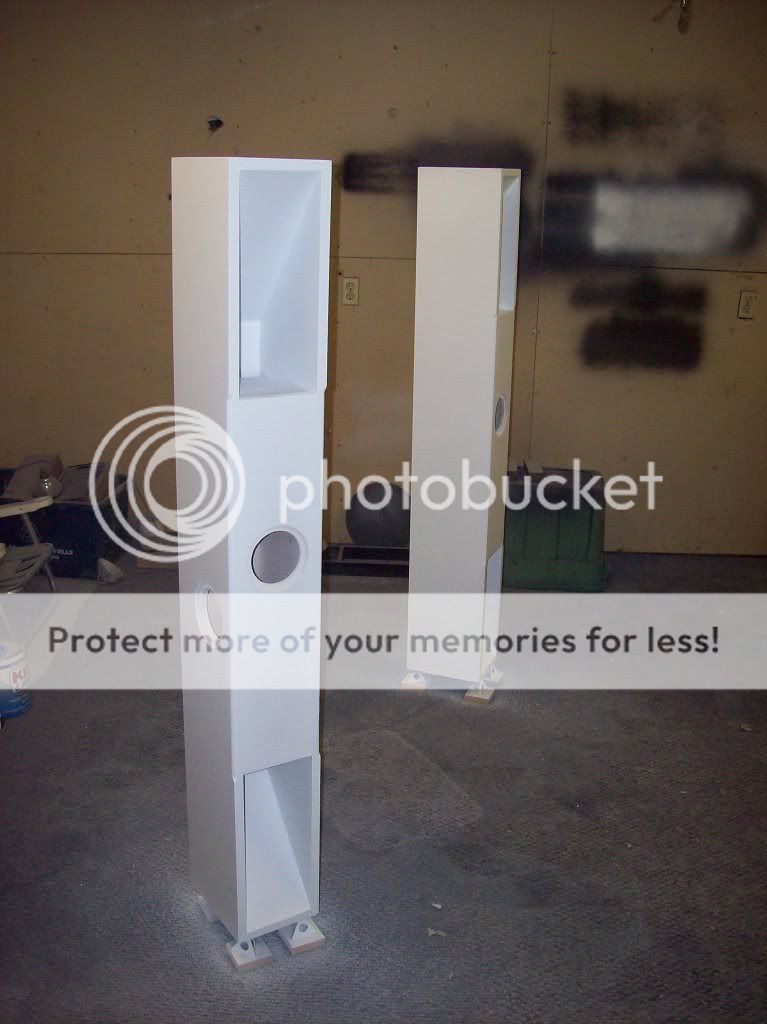

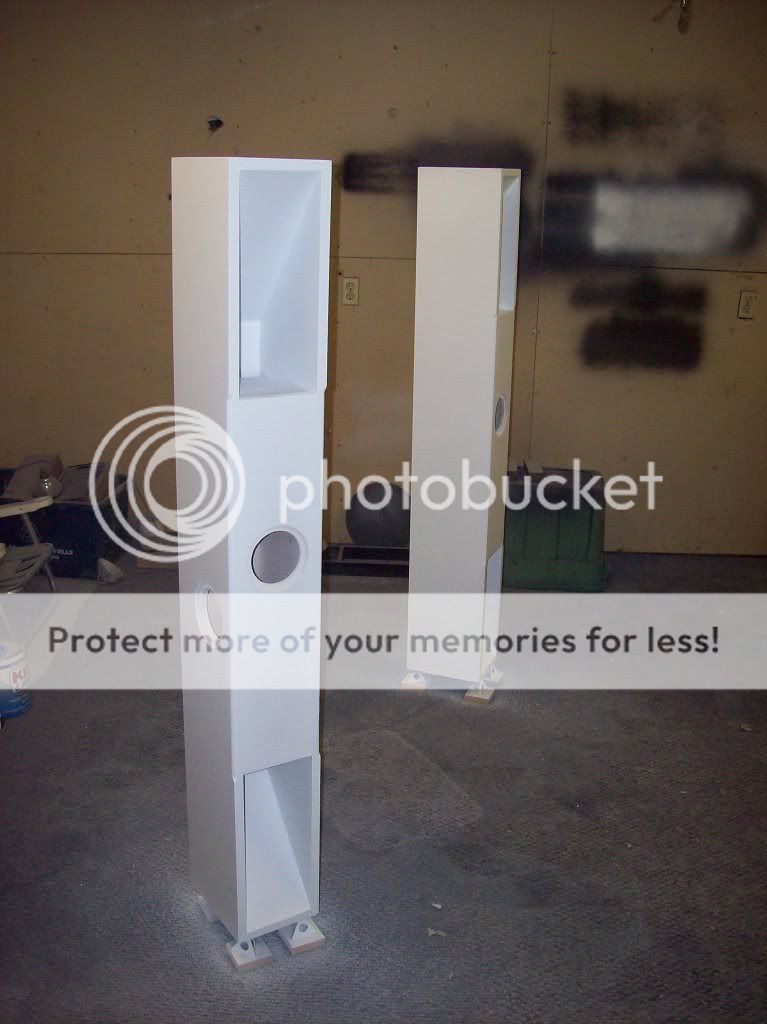

A few more pictures to update on the current progress. I got them sanded and primed (once) and I'll repeat in reverse order (prime then sand). After which I'll put the paint on them. I'm hoping for a decent finish. I really hate painting; have I ever said that?

Can someone tell me what the expected advantage is to have two Mark Audio EL70s in an enclosure? What difference between the twin and a single enclosure? Does the extra speaker firing off to one side give a bigger sound field? more bass? I'm thinking of the Conniston of course. I built the G changs last year (which I think are great) also the Jordan transmission line enclosures, so I don't need more speakers in the house but need and want are two different things aren't they?

Here is the latest picture of the progress. Sorry for the delay in my work (multiple projects at once). The color scheme is to match a certain room. My friend owns a hair salon and their place is all black and white. The cones of the EL70 are black and so is the basket so these should fit right in at his place. I'll run these for a month or two and enjoy them before I give them to him though 🙂

Drivers should go in soon once the paint fully dries.

Drivers should go in soon once the paint fully dries.

Can someone tell me what the expected advantage is to have two Mark Audio EL70s in an enclosure? What difference between the twin and a single enclosure? Does the extra speaker firing off to one side give a bigger sound field? more bass?

Both. And greater dynamics and lower distortion. One technique to get the advanatges of a larger driver without the downsides.

dave

Those look really nice 🙂. I'll be happy if my single driver build of the Coniston turns our looking half as nice.

Ewan

Ewan

splendid job man! is there an easy way to do the flush mounting thing? can someone give me a link to learn it?

get the advanatges of a larger driver without the downsides.

dave

Dave is there a rule of thumb to calculate what driver diameter (being all equal) 2 drivers of given diameter are equivalent to?

splendid job man! is there an easy way to do the flush mounting thing? can someone give me a link to learn it?

The easiest way to flush mount drivers is to use a router and a circle cutting jig. You can buy a commercial circle cutting jig such as the Jasper Jig see here Jasper Circle Cutting Jigs or make your own like this How to Cut Circles and Curves With a Router : How-To : DIY Network or like this Woodworking Tip: Router Circle-Cutting Jig. You then set the jig to the desired diameter of the driver cut out and make several shallow passes with the router until you've achieved the necessary depth of cut out for the driver's faceplate.

Ewan

Dave is there a rule of thumb to calculate what driver diameter (being all equal) 2 drivers of given diameter are equivalent to?

Take the driver Sd, multiply by 2 and then calculate the Sd of a single driver would have the same Sd.

You can just look at the Sds on the spec sheet or you can get the ruler out and do the math, and determine the actual cone diameter of the larger driver (remembering that driver size usually includes the size of the surround & the bezel, ie the EL70 is equivalent to 4" driver and has a 70 mm diameter cone)

2*(pi*(d1/2)^2) = pi*(d2/2)^2

2*sqrt(2*(d1/2)^2) = d2

ie for 2 EL70, d2 = 99 mm so something like a 5.5-6" driver (same as 1 Alpair 10).

dave

Looking really good 🙂

We want a picture installed (and all the cute hairdressers)

dave

Thanks dave! I've got bad news though...there is only one girl that works there if you know what I mean. 😱 Maybe I can bring my girlfriend along and get her to pose instead😀

The easiest way to flush mount drivers is to use a router and a circle cutting jig. You can buy a commercial circle cutting jig such as the Jasper Jig see here Jasper Circle Cutting Jigs or make your own like this How to Cut Circles and Curves With a Router : How-To : DIY Network or like this Woodworking Tip: Router Circle-Cutting Jig. You then set the jig to the desired diameter of the driver cut out and make several shallow passes with the router until you've achieved the necessary depth of cut out for the driver's faceplate.

Ewan

^I use the jasper jig mentioned above. Worth every penny IMO. I build a lot of stuff (you may have noticed) and use mine constantly. Looks brand new still.

...there is only one girl that works there if you know what I mean. 😱 Maybe I can bring my girlfriend along and get her to pose instead😀

Cuties have to be girls? They are my preference, but i'm sure there are some not so predisposed.

dave

Cuties have to be girls? They are my preference, but i'm sure there are some not so predisposed.

dave

Tis true, then I shall take pictures of all in attendance.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- New Build: Coniston^2 dual driver double mouth MBVR