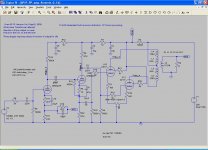

So I have finished wiring my prototype amp.

I'm having a beer after cleaning off the work bench and contemplating what to do next.

I have a resistive load to use in place of the speaker, Bench power supply, etc.

How should I proceed, after rechecking everything tomorrow night?

I can pull all the tubes (except the time delay in the HT/B+) and measure the voltage at each plate, but it will be off because there is no load.

I could substitute resistors from plate to cathode for each stage based on calculated current and voltage drop, and verify the B+ to each tube socket pin.

Then install the input buffer first, and take measurements of it, install the phase splitter and take measurements, install the outputs and take measurements.

Finally after all bias conditions are verified, inject a signal in the input and measure each stage and the output.

.

.

.

.

.

Or I can just plug a set of tubes in and fire it up.

What's your procedure?

Fire extinguisher on hand as well!😱

I'm having a beer after cleaning off the work bench and contemplating what to do next.

I have a resistive load to use in place of the speaker, Bench power supply, etc.

How should I proceed, after rechecking everything tomorrow night?

I can pull all the tubes (except the time delay in the HT/B+) and measure the voltage at each plate, but it will be off because there is no load.

I could substitute resistors from plate to cathode for each stage based on calculated current and voltage drop, and verify the B+ to each tube socket pin.

Then install the input buffer first, and take measurements of it, install the phase splitter and take measurements, install the outputs and take measurements.

Finally after all bias conditions are verified, inject a signal in the input and measure each stage and the output.

.

.

.

.

.

Or I can just plug a set of tubes in and fire it up.

What's your procedure?

Fire extinguisher on hand as well!😱

Attachments

Last edited:

I power it through a lightbulb (150w - poor man's variac) in the first instance... This will ensure that any shorts don't result in home heating.

Then pretty much as you have set out - pull all tubes, check voltages are within expected (unloaded) range, then build from input to output rechecking as I go.

I've only ever had one go right first time, and that was my first, an EL84 SE

My last took several rebuilds and one still on the blocks dropped all the wax out of an old PTX on start-up. Good thing I had the lightbulb dummy loading the power supply...

Don't connect a speaker to the outputs until you've run them with a dummy load and ensured the expected output values are there. Very embarrassing and potentially speaker-destroying otherwise.

My last point - beer definitely helps. Stops your hands shaking.

Then pretty much as you have set out - pull all tubes, check voltages are within expected (unloaded) range, then build from input to output rechecking as I go.

I've only ever had one go right first time, and that was my first, an EL84 SE

My last took several rebuilds and one still on the blocks dropped all the wax out of an old PTX on start-up. Good thing I had the lightbulb dummy loading the power supply...

Don't connect a speaker to the outputs until you've run them with a dummy load and ensured the expected output values are there. Very embarrassing and potentially speaker-destroying otherwise.

My last point - beer definitely helps. Stops your hands shaking.

Tubelab uses goggles and a plexiglass blast shield. That's full of win 🙂

I use goggles and just hit the switch 😀

(usually my only wiring errors are backwards electrolytics)

Cheers!

I use goggles and just hit the switch 😀

(usually my only wiring errors are backwards electrolytics)

Cheers!

I wear glasses (polycarbonate lenses) so they take care of that.

I once (1973) was powering up a AN/ARC153 Power Amp (1KW HF) and forgot to take off my RayBan Photo-gray sunglasses.

The 400Hz Transformer decided to take the day off in a spectacular manner (that called to attention everyone in the Intermediate Maintenance Shop). I had a few facial burns, but the glasses took the brunt of the nasties. They had pitts across the center from molten copper (windings).

I once (1973) was powering up a AN/ARC153 Power Amp (1KW HF) and forgot to take off my RayBan Photo-gray sunglasses.

The 400Hz Transformer decided to take the day off in a spectacular manner (that called to attention everyone in the Intermediate Maintenance Shop). I had a few facial burns, but the glasses took the brunt of the nasties. They had pitts across the center from molten copper (windings).

Powering Up a New Power Amp

I have not built tube amps, but when powering up a solid state amps I usually start by placeing 25-60 watt light bulbs in series with the V+ and V- lines, between the caps and the amplifier module. Incandescent lights are a highly nonlinear resistance that display a built-in current limiting feature. For example, the cold vs. hot resistance of a 60 watt lamp at approximately 10/1. Also, it is easy to determine an overcurrent condition by looking at the brightness of the lamp.

I have not built tube amps, but when powering up a solid state amps I usually start by placeing 25-60 watt light bulbs in series with the V+ and V- lines, between the caps and the amplifier module. Incandescent lights are a highly nonlinear resistance that display a built-in current limiting feature. For example, the cold vs. hot resistance of a 60 watt lamp at approximately 10/1. Also, it is easy to determine an overcurrent condition by looking at the brightness of the lamp.

How to fire up a tube amp for the first time!

Ya know....this question is pretty good....but as it refers to a new construction, I'd say it's just as important if relating to firing up an old amp for the first time in a long while. I have a process that has worked for me without any real problems. However, I should point out that the real failure point it the power supply filter section. In older amps the idea is to bring up the power slowly to charge the caps and 're-form' them. In newer amps the concerns are a bit different. With new power-supply filter caps you should be able to just turn the amp on....however there's an issue with some folks as to sending the HV to the tubes before they warm up. If you are the builder, then you should have confirmed the filament voltage to the tube sockets well before getting to the HV B+ stage. If you built a 'stand-by' switch into your amp, then simply use it. Turn your amp on with the input grounded and the output connected to dummy load of appropriate type.....ohms and watt capability. Let your tubes warm up for a minute or two...then hit the stand-by switch. Assuming it doesn't go "POP"....the next step for me is to hook up and old test speaker. I kill power, remove the dummy load and install the speaker. With the input still grounded, I re-warm the tubes then hit the stand-by switch and put HV to the tubes. Again, if all is well.....nothing will happen. You'll just hear a faint thud when the tube take the voltage...then quiet. Of course, if you've got a parasitic oscillation or some kind of PS Filtration problem....you'll hear all kinds of noise. At that point....turn it off quickly and go back and find your problem. And that's a subject for another post. But, if all goes well....then I turn it off and pull the grounded input and connect my signal generator. Finally, with the signal generator in low output mode (if you've got that) and the frequency set at 1K......I re-warm the amp and then hit the standby. If all is quiet, I begin to slowly raise the output level on my signal generator. If I hear the faint sound of the 1K signal....I keep turning it up.....If all goes well, I move from Low to High level output. Finally.....if I'm really trying to gauge performance, I'll put a scope on the thing and watch the wave pattern. I'll measure the input A/C voltage and at 1 VAC, 1K.....I'll measure output voltage and calculate wattage. Finally, I'll keep cranking up the input to the amp until my wave from starts to clip....and at that point I'll measure my final output power. If necessary, as a builder, I may make some adjustments internally to increase or decrease signal to the final output section in order to keep the amp in the typical sensitivity range. I hope this is helpful. Good luck!! Tom D.

Ya know....this question is pretty good....but as it refers to a new construction, I'd say it's just as important if relating to firing up an old amp for the first time in a long while. I have a process that has worked for me without any real problems. However, I should point out that the real failure point it the power supply filter section. In older amps the idea is to bring up the power slowly to charge the caps and 're-form' them. In newer amps the concerns are a bit different. With new power-supply filter caps you should be able to just turn the amp on....however there's an issue with some folks as to sending the HV to the tubes before they warm up. If you are the builder, then you should have confirmed the filament voltage to the tube sockets well before getting to the HV B+ stage. If you built a 'stand-by' switch into your amp, then simply use it. Turn your amp on with the input grounded and the output connected to dummy load of appropriate type.....ohms and watt capability. Let your tubes warm up for a minute or two...then hit the stand-by switch. Assuming it doesn't go "POP"....the next step for me is to hook up and old test speaker. I kill power, remove the dummy load and install the speaker. With the input still grounded, I re-warm the tubes then hit the stand-by switch and put HV to the tubes. Again, if all is well.....nothing will happen. You'll just hear a faint thud when the tube take the voltage...then quiet. Of course, if you've got a parasitic oscillation or some kind of PS Filtration problem....you'll hear all kinds of noise. At that point....turn it off quickly and go back and find your problem. And that's a subject for another post. But, if all goes well....then I turn it off and pull the grounded input and connect my signal generator. Finally, with the signal generator in low output mode (if you've got that) and the frequency set at 1K......I re-warm the amp and then hit the standby. If all is quiet, I begin to slowly raise the output level on my signal generator. If I hear the faint sound of the 1K signal....I keep turning it up.....If all goes well, I move from Low to High level output. Finally.....if I'm really trying to gauge performance, I'll put a scope on the thing and watch the wave pattern. I'll measure the input A/C voltage and at 1 VAC, 1K.....I'll measure output voltage and calculate wattage. Finally, I'll keep cranking up the input to the amp until my wave from starts to clip....and at that point I'll measure my final output power. If necessary, as a builder, I may make some adjustments internally to increase or decrease signal to the final output section in order to keep the amp in the typical sensitivity range. I hope this is helpful. Good luck!! Tom D.

I did not use a variac. I just plugged in the transformer and watched the lamps. The advantage of lamps is that if everything is OK then the ckt under test operates under nearly the full voltage and does so quickly. A variac cannot guarantee thise conditions, nor can it reacy quickly if something shorts or (more commonly) goes into HF oscillation.

I tend to do the 'test as I build' method. After first having done the build on paper to work out the routing of the wires, component layout and grounding, the first thing I do is the heater wiring. Hook up to the power transformer and test the voltages at the heater sockets. Plug the tubes in and see the glow. Helps keep the motivation passing this little milestone. I then wire up the power supply and test the voltages. I then wire from input following the signal path. As each little step is completed, hook up a signal generator and see if it is working as expected. This helps discover errors as they are made and prevents a big bang destroying multiple components.

Hope this helps,

Chris

Hope this helps,

Chris

Usually just cross my fingers and giver... Once in a while it goes poorly, but it's been a long time... maybe i'm due for another boom.

Usually just cross my fingers and giver... Once in a while it goes poorly, but it's been a long time... maybe i'm due for another boom.

When CBC reports of a province wide power outage, we'll know who it was 😀

Cheers!

- Status

- Not open for further replies.

- Home

- Amplifiers

- Tubes / Valves

- How to power up a new Build the first time