Presenting the Trynergy - a full range tractrix synergy.

This speaker spun-off from the PRV 5MR450-NDY thread here:

http://www.diyaudio.com/forums/full-range/259293-prv-5mr450-ndy-fast-applications-23.html#post4044854

and is sufficiently OT from the main thread which deals with the PRV driver and a FAST implementation that I think it deserves its own thread. The 1.0x scale tractrix horn design was calculated using Volvotreter's tractrix spreadsheet using a 2.78in square throat and a 175Hz flare frequency.

http://volvotreter.de/downloads/Tractrix_v1.4b.zip

The spreadsheet as I used it to build my horns is on post 90 here

http://www.diyaudio.com/forums/full-range/261427-40-full-range-synergy-9.html#post4049422

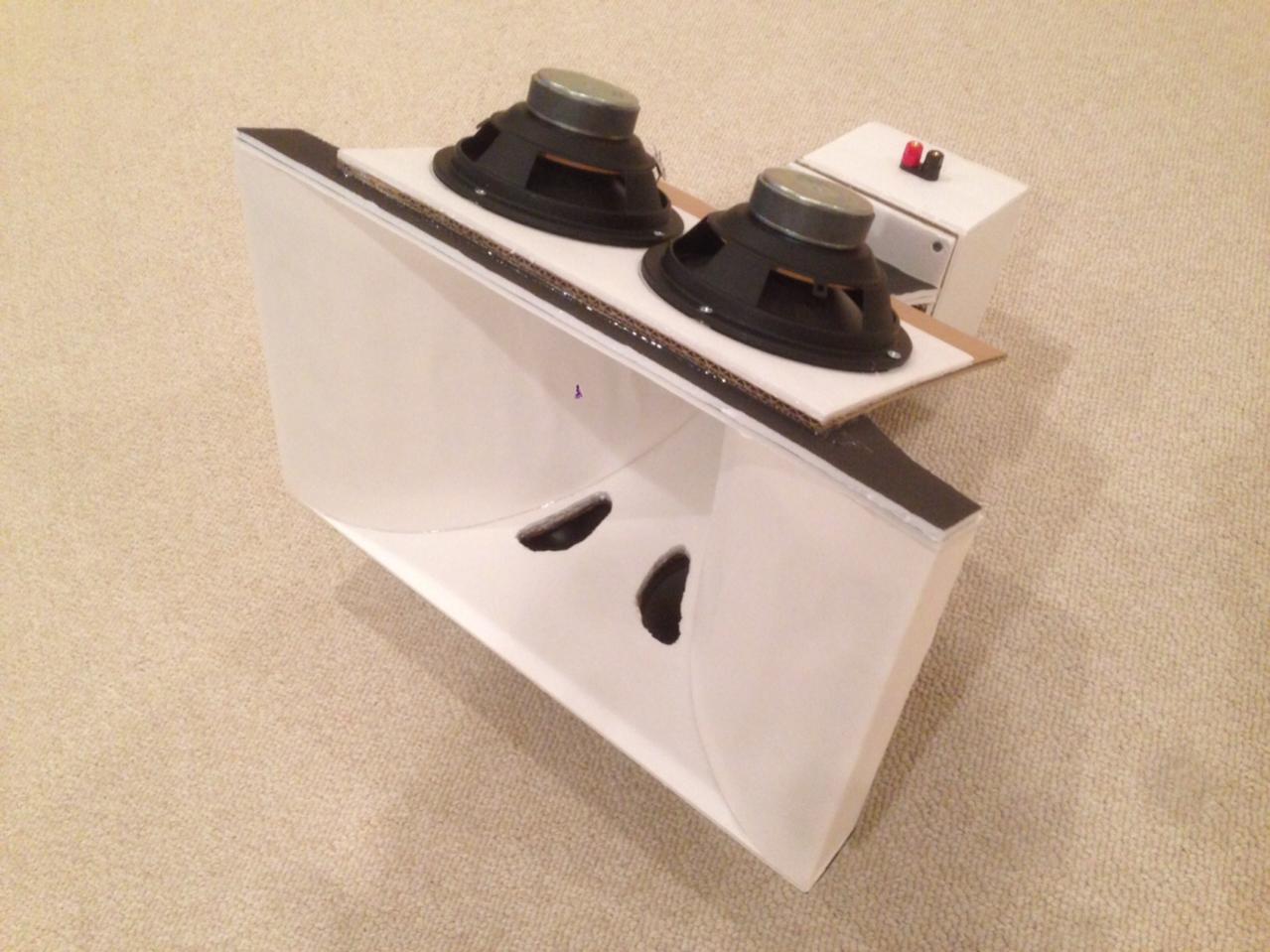

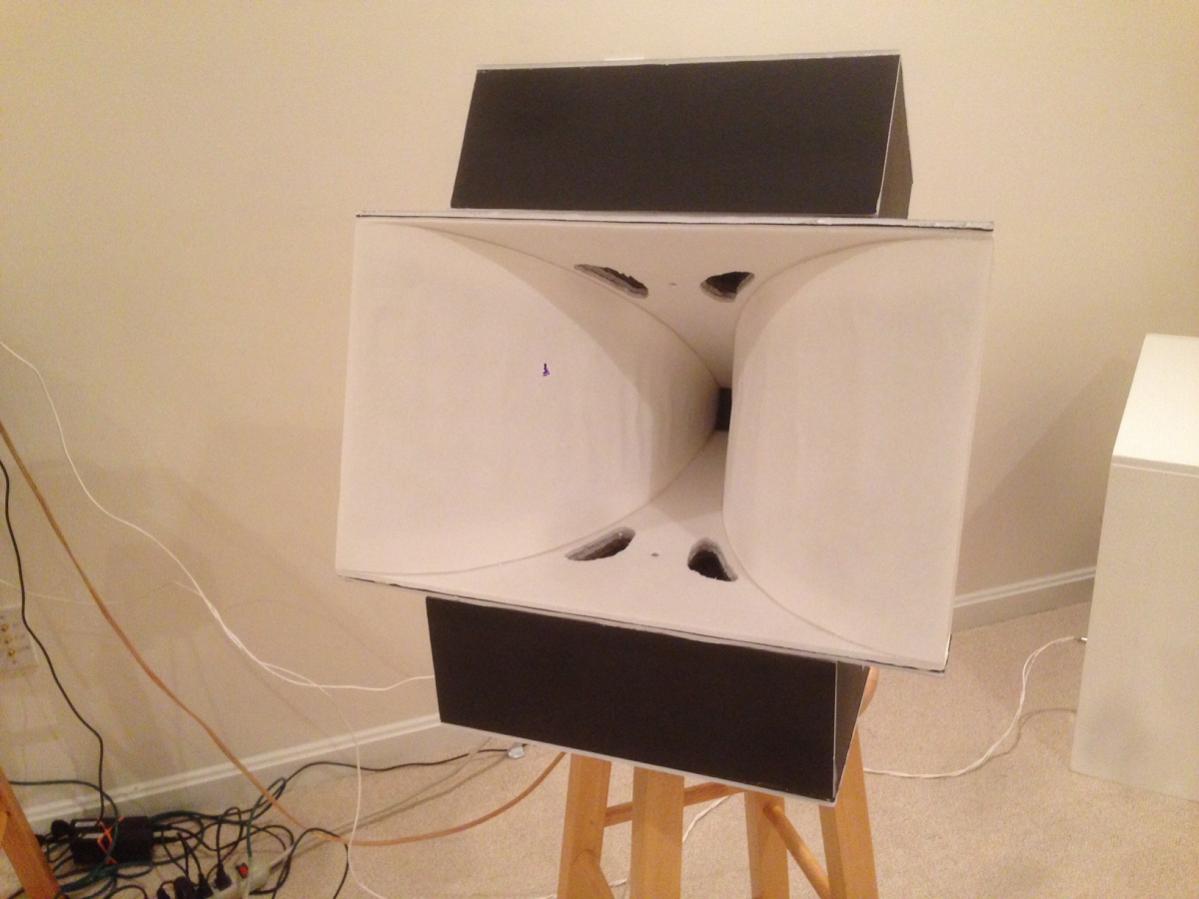

I then took the dimensions from every inch of axial distance and plotted the curve for the horn profile. I then fitted the curve with a two-point spline in Solidworks, then made a 3d model using the lofting tool, then I unrolled the curved shape to a flat 2d pattern using the sheet metal "flatten" tool. This pattern, once cut onto foam core (scored with parallel cuts every 3 to 5 mm on on the concave side) self-formed into the tractrix profile when enforcing the mechanical mates of the mouth, throat, and edge boundary conditions via hot melt glue to the top and bottom panels. For the 0.70x case, the throat is 2.0 in square and the mouth is 20 in wide and horn is 15.3 in deep. Glue the throat section first, then the mouth, then the middle.

Cut plan for 2d panel on post 94 here

http://www.diyaudio.com/forums/full-range/261427-40-full-range-synergy-10.html#post4049533

Here is the cut/glue plan for the flat top and bottom panels on post 175:

http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy-18.html#post4053078

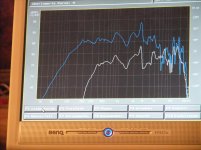

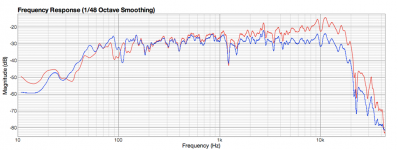

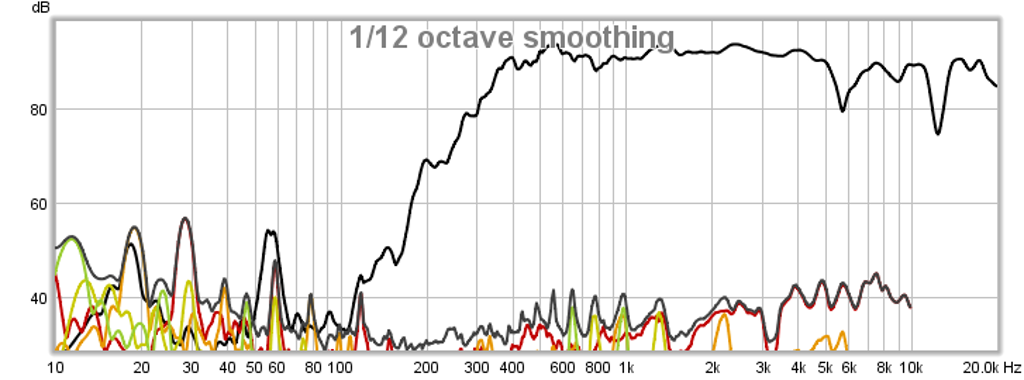

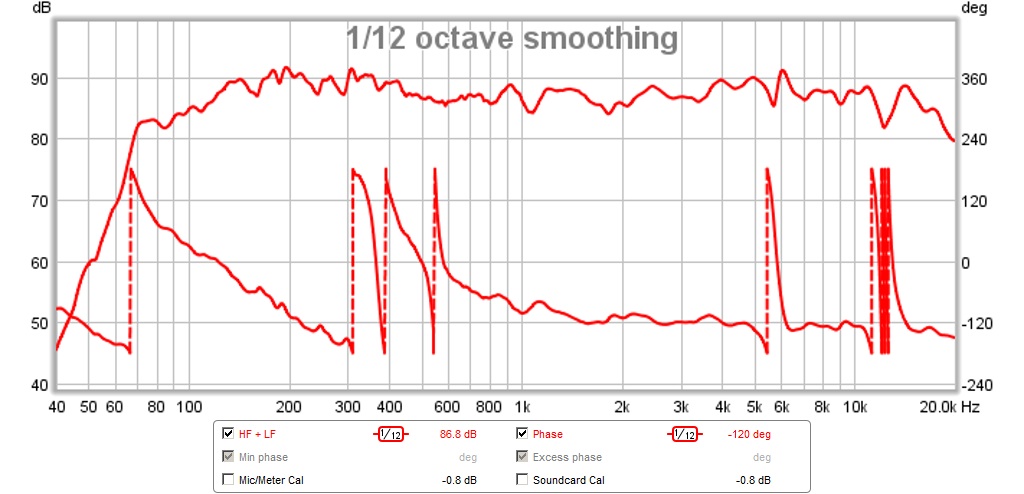

The idea for this speaker came from a large 300Hz 28in wide x 17in tall x 22in deep tractrix horn driven by a full range driver. I then scaled that horn down to 0.70x for a 400Hz 20in wide x 12in tall x 15in deep tractrix. Originally designed with the Faital Pro 3FE25 in mid, I stuck a Vifa TC9FD in it for grins. With some DSP EQ'ing I was able to get the following response from the little Vifa:

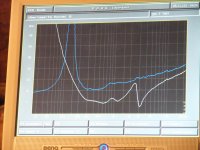

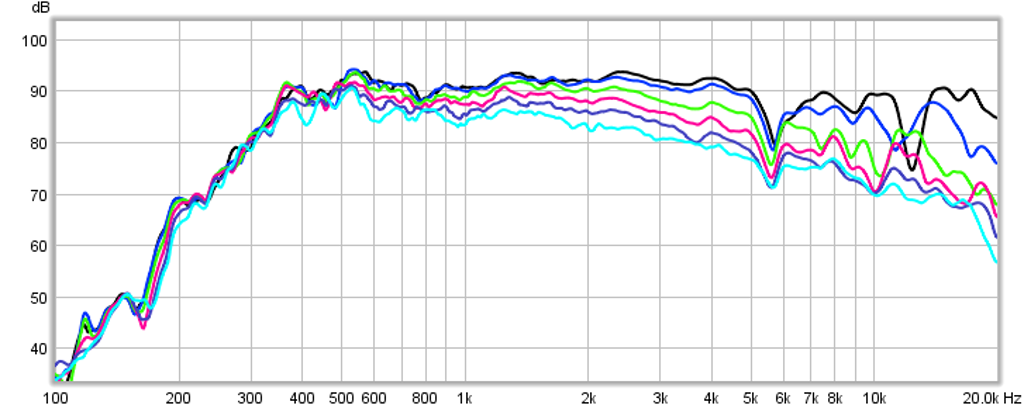

With semi-decent polars:

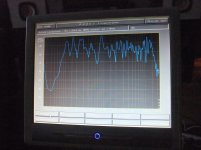

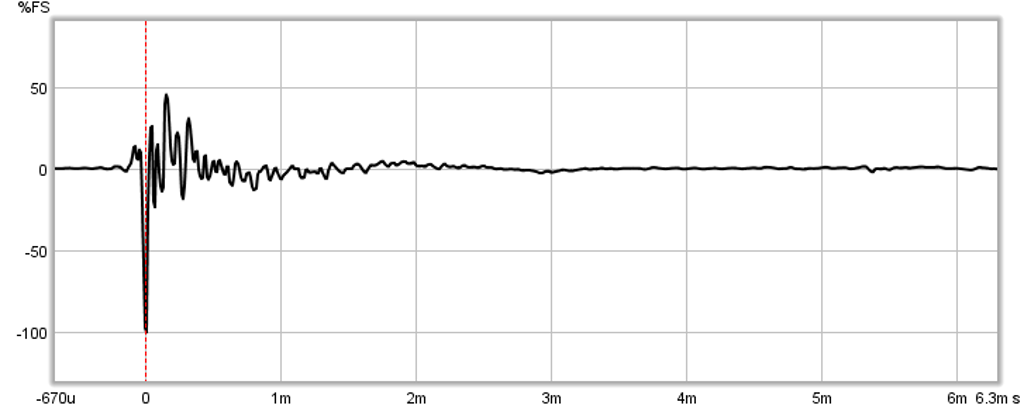

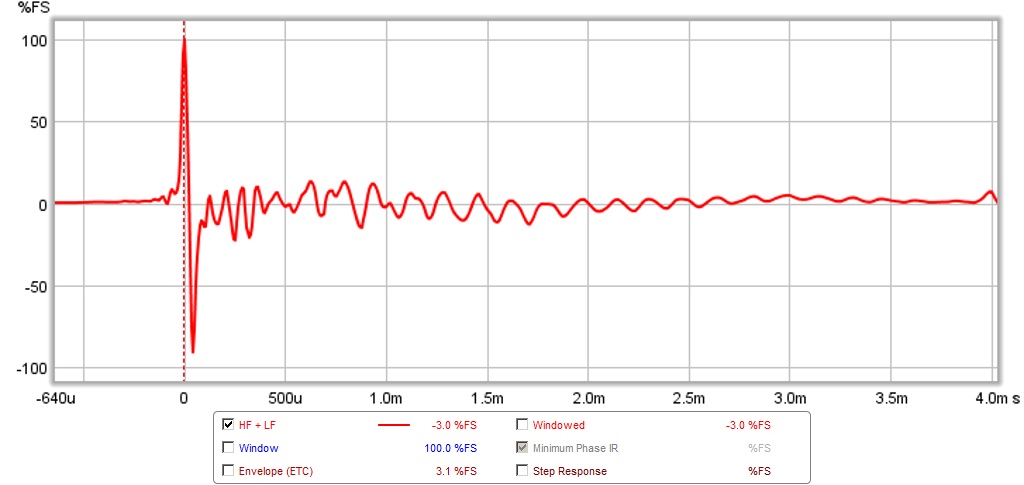

And the Impulse response isn't too shabby either:

Here is a closeup of the horn driver throat flange fitted with the TC9FD (note that a FC spacer with a cutout had to be made to prevent the surround from rubbing the flange plate):

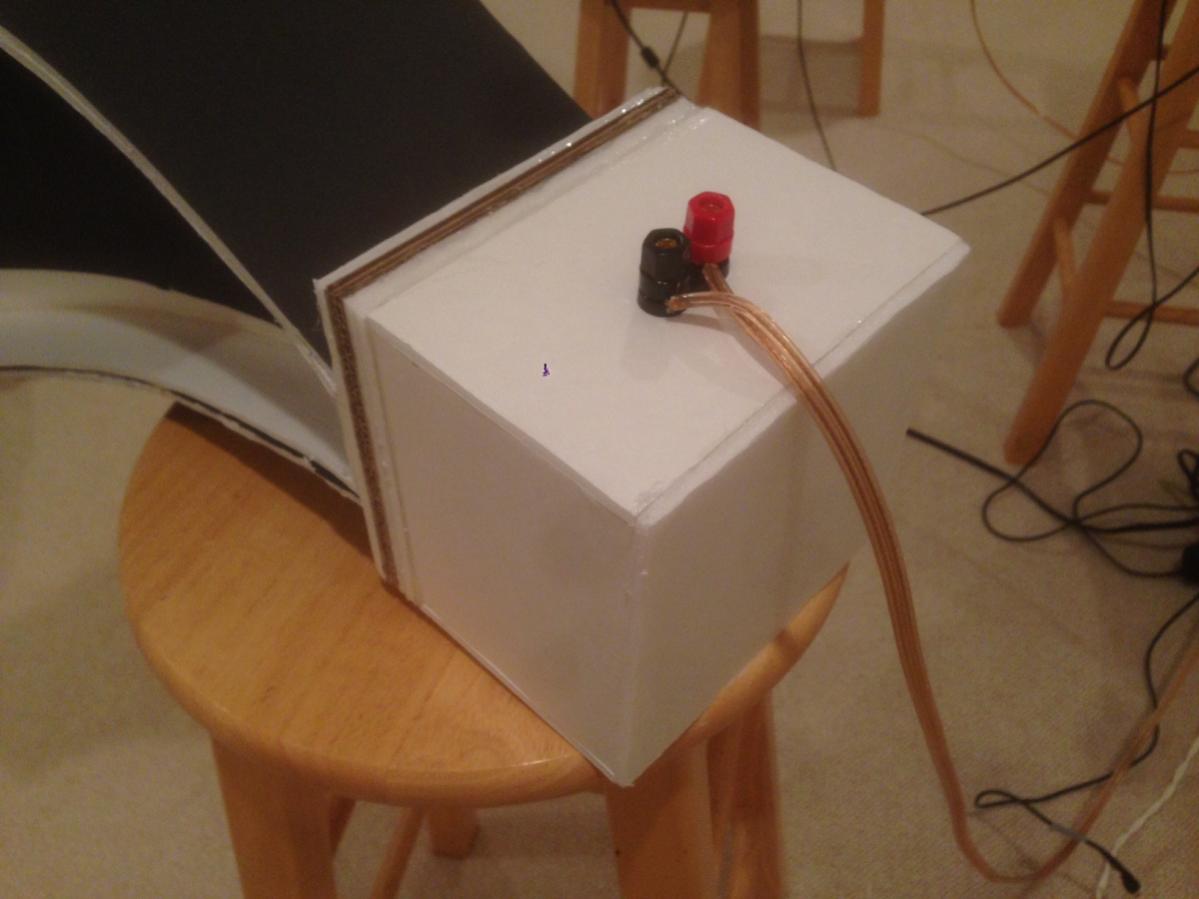

Here is the rear sealed chamber (6in x 6in x 4in and lined with open cell grey foam):

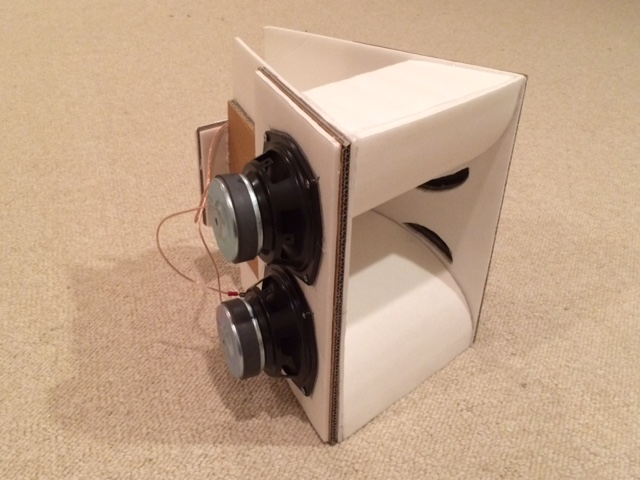

Here is the horn before I put the woofers on (note the black panels on top of the white panels - those are the constrained layer damping (CLD) layers used to reduce panel resonances using latex caulking in between the white horn walls and the black foam sheets):

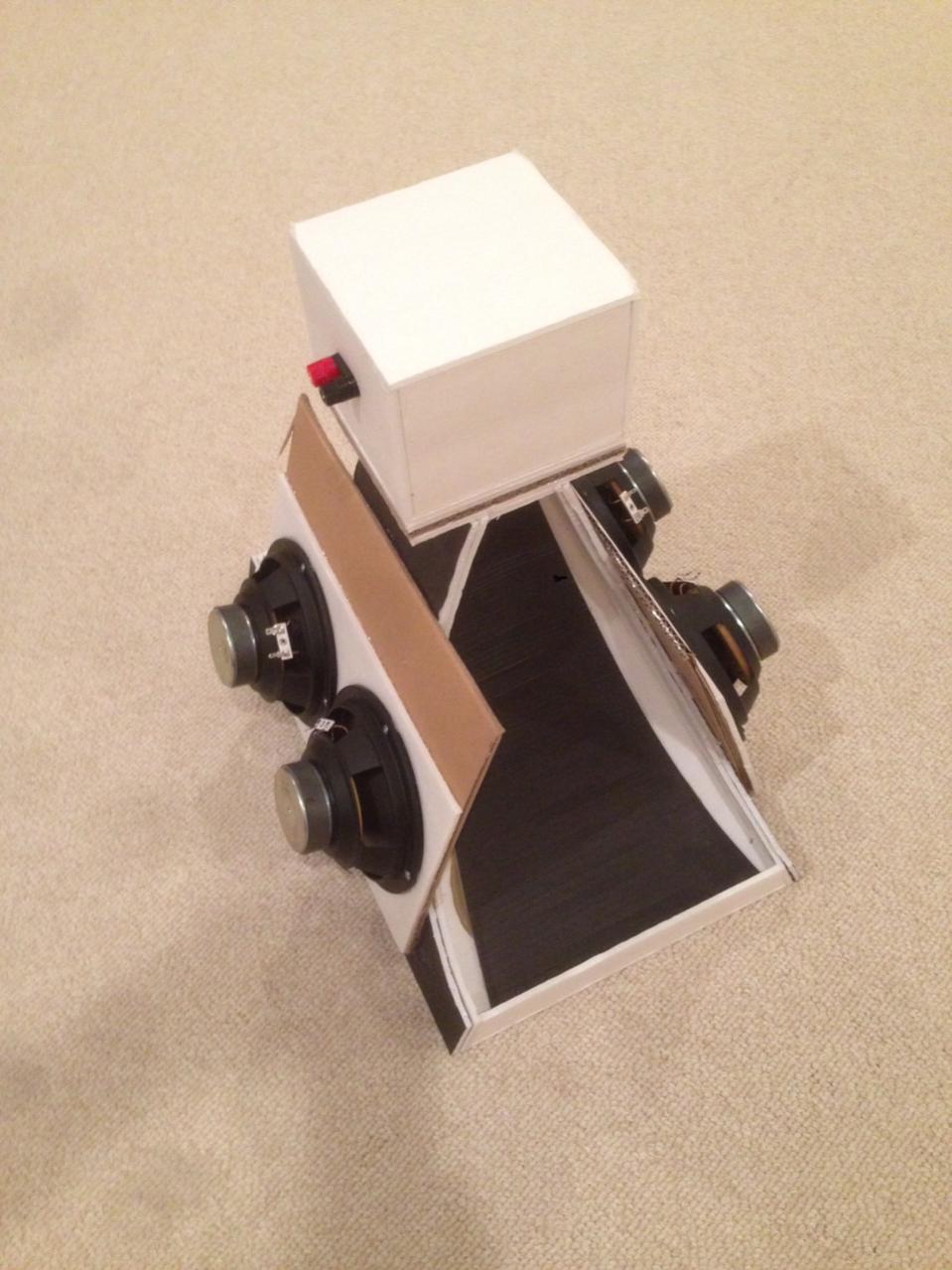

I normally model stuff before building, but in this case, I had some buyout PE 6.5in woofers lying around. There is only so many ways to fit these drivers into the tractrix so I went for the build it as you go approach sans modeling and got this after 90 minutes of cutting foam core/cardboard and hot glue:

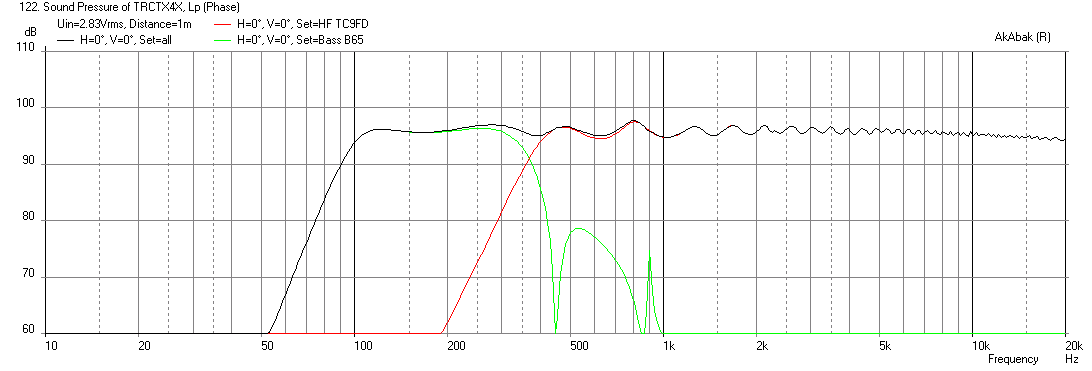

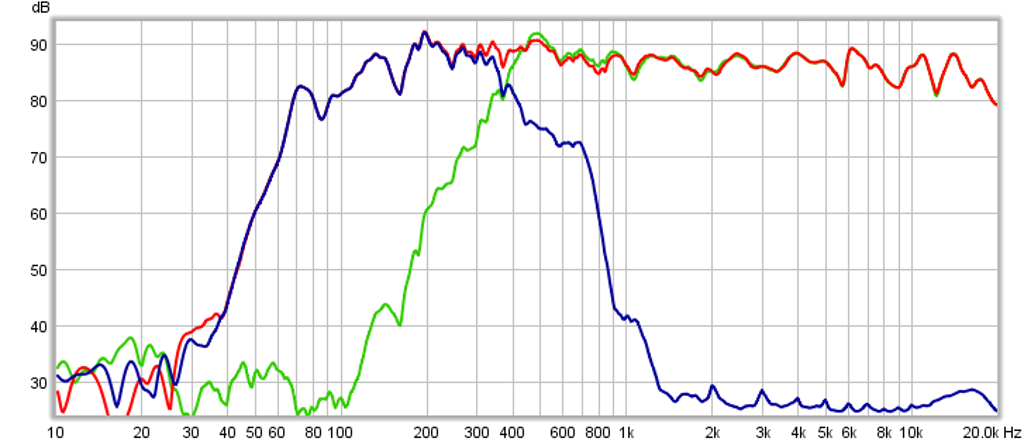

After building it, I then modeled it and saw that it needs a rear sealed chamber on the woofers otherwise there is no bass to speak of due to proximity of the backside of woofers and the mouth causing cancellation. Here is the predicted response with the woofers and the TC9FD:

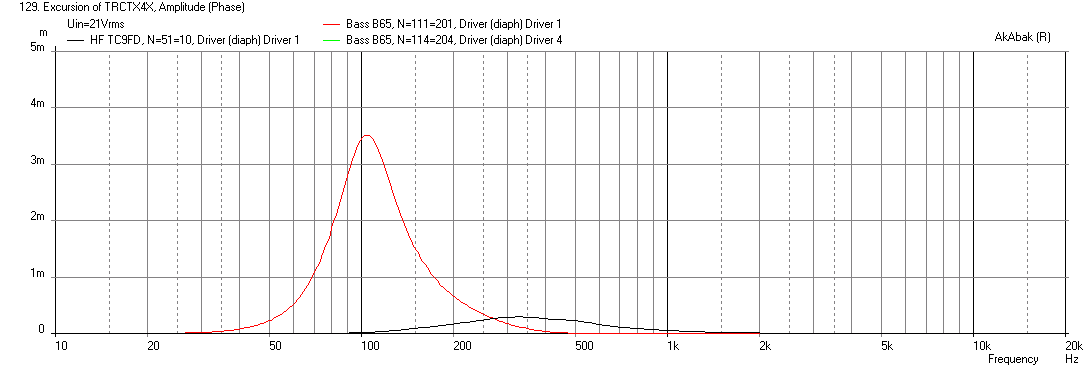

With 3.5 mm xmax being reached at 21 volts:

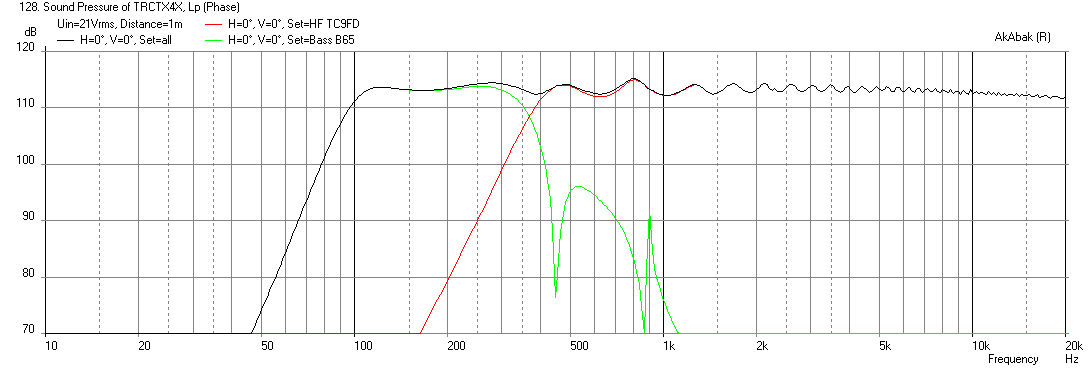

Giving a corresponding max SPL capability of about 113dB at 1m and 21v:

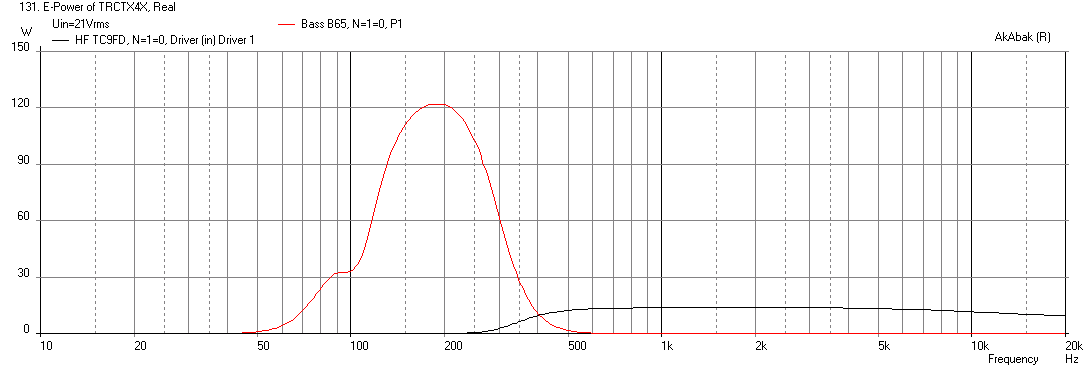

With the corresponding electrical power input predicted to be 30 watts per 6.5 in driver, which is OK per the manufacturer's rating:

The $40 cost break down is as follows:

- Qnty 4 Parts Express buyout 6.5 in polycone woofers (same driver as used in ther well-regarded B652 speakers) $5 ea x 4 = $20

- Qnty 1 Vifa TC9FD driver $12

- 4 sheets of foam core $4

- 1 tube of latex caulking for the constrained layer damping $2 (n.b., DO NOT use Liquid Nails - as the solvent vapors will melt the foam in the foam core!)

- 1 dual banana post binding terminal $1 ( Edit: technically $3 now with qnty 3 binding posts)

- Hot melt glue sticks $1

Note that you will need active EQ and bi-amping to make this work. It is not a passive speaker. If you have a miniDSP 2x4 and a couple of amps you are set. If you need tips on how to do this, check out the "Cheap and FAST OB, Literally" thread.

I still need to install the rear sealed chamber and get a measurement with the woofers on.

Let's see if a point source synergy speaker can be built for $40 and if it sounds good. Stay tuned!

Measurements and sound clips to follow.

Update Sept 3, 2014: the tractrix fullrange Synergy is completed and it sounds wonderful! See post 13.

Edit Sept 4, 2014: New tweaks on EQ provide linear phase from 600Hz to 5kHz and cleaner impulse response. Note all data smoothed at 1/12th octave.

Edit: Sept 7, 2014 - Faital Pro 3FE22 driver with 4-way miniDSP XO and bass horn sub.

Edit: Sept 12, 2014 - How to adjust and optimize time alignment between HF and mid woofers - http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy-20.html#post4055704

Edit: Sept. 20, 2014 - Stereo pair completed,

sound clips in post 269 http://www.diyaudio.com/forums/full-range/261427-presenting-trynergy-full-range-tractrix-synergy-27.html#post4063999

Edit (Dec 14, 2015) - micro Trynergy with 13 X 8.5in mouth and 2in driver:

More info here

http://www.diyaudio.com/forums/full...l-range-tractrix-synergy-108.html#post4544312

Edit (Dec 20, 2015): uTrynergy in a dipole bass enclosure - more info here

Presenting the Trynergy - a full range tractrix synergy.

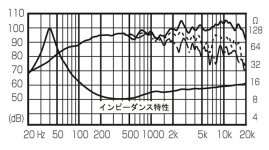

translation: "Does anyone know what these speakers are like? Weight 25 kilograms of Audax speakers"

translation: "Does anyone know what these speakers are like? Weight 25 kilograms of Audax speakers"