http://www.mouser.com/catalog/catalogUSD/643/669.pdf

http://www.mouser.com/catalog/catalogusd/643/667.Pdf

FYI on inductance in resistors and the difference in noise level between thick and thin film types.

But for a bit of humorous controversy I just installed plastic AC outlet fillers in all my shop unused receptacles. This has improved the quality of the FM Radio sound system in the shop. Really! Does stopping the leaking electricity really have this effect, if not why the improvement?

http://www.mouser.com/catalog/catalogusd/643/667.Pdf

FYI on inductance in resistors and the difference in noise level between thick and thin film types.

But for a bit of humorous controversy I just installed plastic AC outlet fillers in all my shop unused receptacles. This has improved the quality of the FM Radio sound system in the shop. Really! Does stopping the leaking electricity really have this effect, if not why the improvement?

Too complicated! Easier answer.Schumann resonance. It's the only explanation.

VD, cap comparisons apparently fail to show much in a double blind test. That is why we don't use them. Walt Jung, the co-author of our Cap paper from 1985, once submitted the WORST sounding Tantalum caps that he had found, to Dr. Lipshitz and his associates, and they could not measure any differences with a double blind test. This just shows that the test gives contrary results to what we 'hear', and it is generally 'useless'.

It is NOT because we have not tried them, that we don't use them, but they don't give us any useful information as to component differences, so we don't use them, everyone.

It is NOT because we have not tried them, that we don't use them, but they don't give us any useful information as to component differences, so we don't use them, everyone.

Hi,

For what it is worth, at AMR's main lab we have a very special "device".

It is actually fundamentally a copy of the Audio Note Japan (Kondo) M7 Line Preamplifier, in principle.

However, each and every component (including tubes) are rewirable using barrier strips, each passive component is switchable for multiple positions fitted with barrier strips.

Subjective testing of any passive components, capacitors, resistors, even power supply chokes is done using this "device" and blind.

To be precise, the tests are single blind insofar that A/B/C are always clearly identified, however the identity of A/B/C is unknown (they may even on occasion be all the same just throw spanners in the works), however they are normally also blind to the nature of the device tested (e.g. it may be resistors, capacitors, tubes, or even attenuators or power transformers/chokes), to ensure that there is no expectation bias. Tests are done with multiple listeners, though often not at the same time (some times multiple listeners in the same room must be allowed for logistical reasons.

In order to avoid seeming to be making any "extraordinary claims", I shall not comment if the tests support sonic differences or not.

However, I can say that if we posit that such existed (which I do not claim they do in actuality), the process used should be most excellent in removing bias and imagination and if the posited differences actually existed it would be usually easy to attain a consensus among multiple listeners which item would be preferred and indeed to get very similar descriptions of the sonic properties.

As it is, without presenting evidence or making claims, AMR uses this "device" regularly to evaluate parts, in addition to performing conventional measurements with parts considered for inclusion.

Many never make it to the "device" as they fail "conventional" measurements (like one alternative vendors organic semiconductor electrolytic capacitors, which had 30dB ESR and 60dB worse noise/distortion than the reference ones).

Whenever I hear people telling me "all sounds the same", demand "evidence" and so on, I consider the objective and subjective results I have access to and: "Sit on my eighth of laurel leaf, and do just as I wilt!"

Ciao T

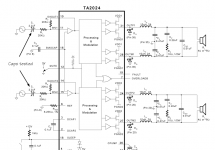

I was testing if a difference could be heard by changing the input cap of a Tripath amp.

...snipping...

This was a specific test in a specific application. I kept notes. I picked what I liked on music. Testing was done over headphones.

For what it is worth, at AMR's main lab we have a very special "device".

It is actually fundamentally a copy of the Audio Note Japan (Kondo) M7 Line Preamplifier, in principle.

However, each and every component (including tubes) are rewirable using barrier strips, each passive component is switchable for multiple positions fitted with barrier strips.

Subjective testing of any passive components, capacitors, resistors, even power supply chokes is done using this "device" and blind.

To be precise, the tests are single blind insofar that A/B/C are always clearly identified, however the identity of A/B/C is unknown (they may even on occasion be all the same just throw spanners in the works), however they are normally also blind to the nature of the device tested (e.g. it may be resistors, capacitors, tubes, or even attenuators or power transformers/chokes), to ensure that there is no expectation bias. Tests are done with multiple listeners, though often not at the same time (some times multiple listeners in the same room must be allowed for logistical reasons.

In order to avoid seeming to be making any "extraordinary claims", I shall not comment if the tests support sonic differences or not.

However, I can say that if we posit that such existed (which I do not claim they do in actuality), the process used should be most excellent in removing bias and imagination and if the posited differences actually existed it would be usually easy to attain a consensus among multiple listeners which item would be preferred and indeed to get very similar descriptions of the sonic properties.

As it is, without presenting evidence or making claims, AMR uses this "device" regularly to evaluate parts, in addition to performing conventional measurements with parts considered for inclusion.

Many never make it to the "device" as they fail "conventional" measurements (like one alternative vendors organic semiconductor electrolytic capacitors, which had 30dB ESR and 60dB worse noise/distortion than the reference ones).

Whenever I hear people telling me "all sounds the same", demand "evidence" and so on, I consider the objective and subjective results I have access to and: "Sit on my eighth of laurel leaf, and do just as I wilt!"

Ciao T

Last edited:

Too complicated! Easier answer.

They keep the bad vibes of the work boxes from getting out? Now go and machine some delrin ones and report back.

They keep the bad vibes of the work boxes from getting out? Now go and machine some delrin ones and report back.

Getting closer, but it is the other direction and it is the result of vibes!

Can You post here simplified circuit, how was this cap conected?

Here is a not so simple schematic of how it was connected. There was a 50K pot between the signal source and the cap. Very typical use.

SY. No control for other sensory inputs. It was a sighted test. The only control was to repeat it several times over several days and keep notes. If my notes agreed, then I felt there was really a difference. Some of my favs lost in this test. I was hoping for small and cheap and good. Didn't find it. That's why the Janztens became the cost/size/quality champs for me. I did not test anything high dollar like Mundorf.

Attachments

SY. No control for other sensory inputs. It was a sighted test. The only control was to repeat it several times over several days and keep notes.

You know what comes next...

I was cutting some aluminum channel when it became clear to me why the music system would be improved by the addition of the plastic bits.

This picture may help explain why my music sounded better after I installed the plastic shields.

So even really stupid sounding changes may have a basis in reality. The other benefit is that it may help prevent my shop from burning down!

This picture may help explain why my music sounded better after I installed the plastic shields.

So even really stupid sounding changes may have a basis in reality. The other benefit is that it may help prevent my shop from burning down!

Attachments

You know what comes next...

Sure. But I did not claim it to be a bullet proof scientific test. Just the best I could do at the time. I'm still pretty confident in the results, as I did my best to keep track. It was not always consistent, so that figured in.

Sometimes you just gotta say "Oh, I don't like the way that sounds" and live with it. These days armed with better test equipment and more knowledge, I'd try to find out why they sounded different. But I'd still listen first, test second.

I was cutting some aluminum channel when it became clear to me why the music system would be improved by the addition of the plastic bits.

This picture may help explain why my music sounded better after I installed the plastic shields.

So even really stupid sounding changes may have a basis in reality. The other benefit is that it may help prevent my shop from burning down!

Again your reasoning escapes me. The plugs don't touch the aluminum and the outlet holes aren't exactly direct acoustic channels to the insides. I see you already tried to burn the house down.

Again your reasoning escapes me. The plugs don't touch the aluminum and the outlet holes aren't exactly direct acoustic channels to the insides. I see you already tried to burn the house down.

Pano, Bingo!

The dust goes everywhere, including behind the plugs. It caused a short circuit, which tripped the breaker, then the music lost volume. Cleaning the dust out, not allowing it back in and resetting the breaker, for some strange reason, the music regains volume!

It ain't exactly a house, sheesh we can't agree on anything.

If you look closely at the picture you can see aluminum dust mixed with saw dust, a really great mixture!

You must have really pelted it for the aluminum dust to make a bridge. I'm impressed!

Actually it made a nice big flash setting off some dust around the arc.

I have a 12" miter saw set up to cut aluminum up to about 6" x 3". Comes in handy on the small stuff. Up to 12" or so we can horizontal bandsaw.

Actually it made a nice big flash setting off some dust around the arc.

I have a 12" miter saw set up to cut aluminum up to about 6" x 3". Comes in handy on the small stuff. Up to 12" or so we can horizontal bandsaw.

Funny, it reminds me of the time I ran out of #10 finishing nails while installing kickboard. Had some #16 and thought longer is better.....

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part II