Post #3017

Hi littlemike,

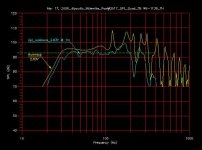

Thank you for posting the additional measurement. I drew it together with the Hornresp data for comparison (hope I got it right). This experiment turned out very well. Even the missing peak @120Hz can still be seen as a remnant in the outdoor curve.

Regards,

Hi littlemike,

Thank you for posting the additional measurement. I drew it together with the Hornresp data for comparison (hope I got it right). This experiment turned out very well. Even the missing peak @120Hz can still be seen as a remnant in the outdoor curve.

Regards,

Attachments

littlemike said:A quick RTA check indicated that the response of the entire system was a little bass-heavy, but otherwise flat. .

sounds good to me... congrats on a success

When it sounds balanced low bass to upper bass to mid to treble, tell us what average voltage is being fed to each driver.littlemike said:The sub amplifier gain is set pretty low - approximately 25%, but the sub still outruns the rest of the system. A quick RTA check indicated that the response of the entire system was a little bass-heavy, but otherwise flat. Dropping the gain on the sub amp a touch more should even things out.

I think your result will surprise most readers.

I'm ready for it, but most builders will not believe me, maybe you'll be able to convince the doubters.

As the sub has now found its way home to my brother's home theater system, I doubt I'll be measuring anything else on this build. All that remains is for him to complete the integration of the sub into the system by matching drive levels and setting appropriate delays. My brother's AV receiver automates all of these settings, plus has independent equalization for all channels, so integration is not that complicated, just time consuming.

As it sits now, the sub is corner loaded against sub-grade walls, so at 2.83 V I'd expect something close to 105 dB. This is well in excess of the main speaker sensitivity (90 dB according to the manufacturer), so the primary part of integration is simply a matter of adjusting the respective amplifier gains appropriately. We had the sub's level too high (as is common with a new sub) and I ran out of time to adjust it with him.

This sub is powerful. When I turned up the sub amp, the bass was sufficient to blur vision, take breath away, and move the sheetrock. As the sheetrock is still rather new, we did not wish to create any cracks and turned things down quickly.

The success with this build has certainly motivated me to do more experimenting, and I have plenty of other drivers and ideas to play with. Just like everyone else - I have far too many other things on my plate to get all my speaker projects done, but I have lots more ideas I want to try. Thank you all for your support and feedback, hope that I've inspired some others to make some sawdust, then share your ideas and results.

As it sits now, the sub is corner loaded against sub-grade walls, so at 2.83 V I'd expect something close to 105 dB. This is well in excess of the main speaker sensitivity (90 dB according to the manufacturer), so the primary part of integration is simply a matter of adjusting the respective amplifier gains appropriately. We had the sub's level too high (as is common with a new sub) and I ran out of time to adjust it with him.

This sub is powerful. When I turned up the sub amp, the bass was sufficient to blur vision, take breath away, and move the sheetrock. As the sheetrock is still rather new, we did not wish to create any cracks and turned things down quickly.

The success with this build has certainly motivated me to do more experimenting, and I have plenty of other drivers and ideas to play with. Just like everyone else - I have far too many other things on my plate to get all my speaker projects done, but I have lots more ideas I want to try. Thank you all for your support and feedback, hope that I've inspired some others to make some sawdust, then share your ideas and results.

Nice work Mike. I'll have to measure my TH one of these days, but its always good to see others getting result consistent with what HR predicts.

littlemike said:This sub is powerful. When I turned up the sub amp, the bass was sufficient to blur vision, take breath away, and move the sheetrock. As the sheetrock is still rather new, we did not wish to create any cracks and turned things down quickly.

littlemike_quad W6-1139

Hi littlemike,

It's good to see a documented and measured build coming to a successful completion. Just a few more requests , could you share the external dimensions of your enclosure, and the mouth opening dimensions; and it would be great if you could give your subjective impressions after you have had a chance for a listening session, music as well as home theater. Thanks again.

, could you share the external dimensions of your enclosure, and the mouth opening dimensions; and it would be great if you could give your subjective impressions after you have had a chance for a listening session, music as well as home theater. Thanks again.

Regards,

Hi littlemike,

It's good to see a documented and measured build coming to a successful completion. Just a few more requests

Regards,

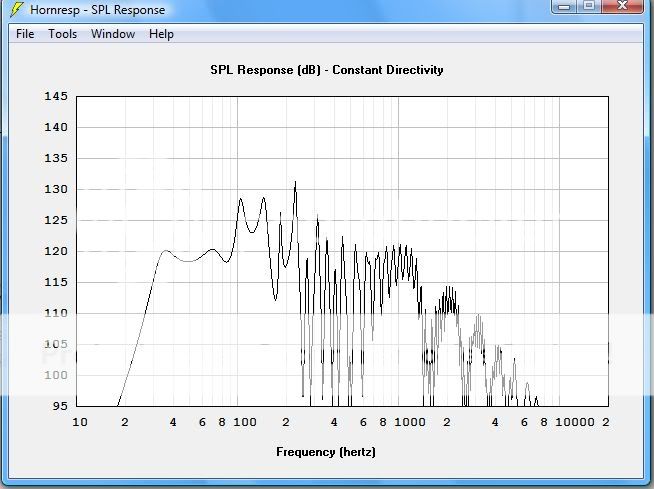

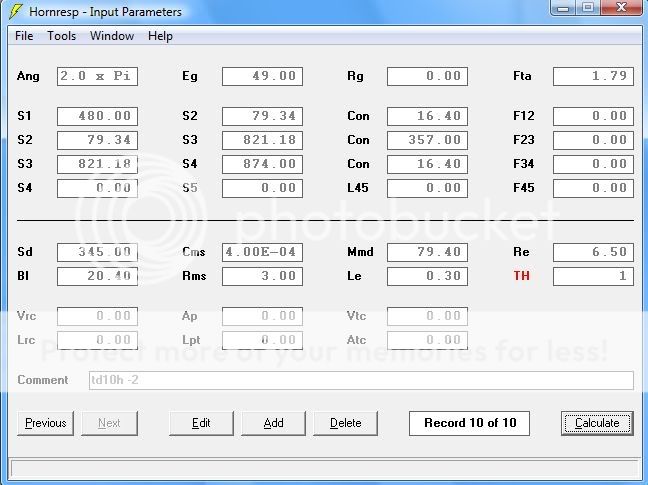

fb_TD10H

Hi,

The experts advise a compression ration below 3:1. In other words S2 should not be smaller than 115cm^2 for this driver. If you watch the comments bar at the bottom of the Hornresp input screen, it will tell you the compression ratio you are using.

Regards,

Hi,

The experts advise a compression ration below 3:1. In other words S2 should not be smaller than 115cm^2 for this driver. If you watch the comments bar at the bottom of the Hornresp input screen, it will tell you the compression ratio you are using.

Regards,

@ tb46

A few answers and some final thoughts:

Dimensions were listed in Post 2982.

External dimensions were 77" long, 19" wide, just under 8-1/2" high

Constructed of 3/4" nominal OSB (Actual thickness was 23/32")

Baffles and horn plates were 7" wide (same as the diameter of the drivers)

Mouth area is 7" X just over 16" (baffle height by cabinet width - 4 thicknesses of OSB) (about 722 cm^2) which is a bit less than the screenshot of the model I posted, though this change does not affect the response curve.

I'll probably not get back to my brother's place for at least a few weeks. Once I have a chance to listen a bit more critically, I should be able to provide some more impressions. The sound was clean and quick, low bass guitar and percussion sounded great. Keep in mind I'm no golden-eared audiophile, and might be a little bit biased, but it sounds good to me (and it measured pretty good too...which probably means more than my ears).

Things I learned from this exercise:

Damping the throat with batting seems to work.

Compression ratios above 3 seem to work (with some drivers in a home environment)

Measurements of what you built are fundamental in understanding the results, and are not that hard to do.

Mounting drivers on studs is not a good idea.

Hurricane nuts do not work that well in OSB.

As far as armchair quarterbacking - I'd definitely change a few things too.

I'd back-mount the drivers in a deeper compression chamber rather than try to front-mount these drivers - they are really not designed for front-mounting.

I'd have used MDF for the baffle boards - hurricane nuts do not hold well enough in OSB.

I'd have chosen a lower -3dB point for the subsonic filter (I picked 30 Hz, but I should have chosen a filter that was flat to 30 Hz (fc of about 15 Hz, Q .7071)

I could have built the box a bit longer (had another 8 inches of space I could have used, meaning I could have added about 16 inches or 40 cm of horn).

Finally, the jury is still out on using OSB. It was nicer to work with than either MDF or the cheap imported plywood from Home Depot, it seems plenty strong, and is relatively cheap, not to mention lighter than MDF.

A few answers and some final thoughts:

Dimensions were listed in Post 2982.

External dimensions were 77" long, 19" wide, just under 8-1/2" high

Constructed of 3/4" nominal OSB (Actual thickness was 23/32")

Baffles and horn plates were 7" wide (same as the diameter of the drivers)

Mouth area is 7" X just over 16" (baffle height by cabinet width - 4 thicknesses of OSB) (about 722 cm^2) which is a bit less than the screenshot of the model I posted, though this change does not affect the response curve.

I'll probably not get back to my brother's place for at least a few weeks. Once I have a chance to listen a bit more critically, I should be able to provide some more impressions. The sound was clean and quick, low bass guitar and percussion sounded great. Keep in mind I'm no golden-eared audiophile, and might be a little bit biased, but it sounds good to me (and it measured pretty good too...which probably means more than my ears).

Things I learned from this exercise:

Damping the throat with batting seems to work.

Compression ratios above 3 seem to work (with some drivers in a home environment)

Measurements of what you built are fundamental in understanding the results, and are not that hard to do.

Mounting drivers on studs is not a good idea.

Hurricane nuts do not work that well in OSB.

As far as armchair quarterbacking - I'd definitely change a few things too.

I'd back-mount the drivers in a deeper compression chamber rather than try to front-mount these drivers - they are really not designed for front-mounting.

I'd have used MDF for the baffle boards - hurricane nuts do not hold well enough in OSB.

I'd have chosen a lower -3dB point for the subsonic filter (I picked 30 Hz, but I should have chosen a filter that was flat to 30 Hz (fc of about 15 Hz, Q .7071)

I could have built the box a bit longer (had another 8 inches of space I could have used, meaning I could have added about 16 inches or 40 cm of horn).

Finally, the jury is still out on using OSB. It was nicer to work with than either MDF or the cheap imported plywood from Home Depot, it seems plenty strong, and is relatively cheap, not to mention lighter than MDF.

Post #3030

Hi littlemike,

Thank you for the additional information, and I'm looking forward to further impressions. I also agree with your comment about measurements. I hope to be able to find the time to create a little sawdust myself, at least I have most of the equipment and the speakers (somewhere around here). Naturally, next weekend is already booked for plumbing.

Regards,

Hi littlemike,

Thank you for the additional information, and I'm looking forward to further impressions. I also agree with your comment about measurements. I hope to be able to find the time to create a little sawdust myself, at least I have most of the equipment and the speakers (somewhere around here). Naturally, next weekend is already booked for plumbing.

Regards,

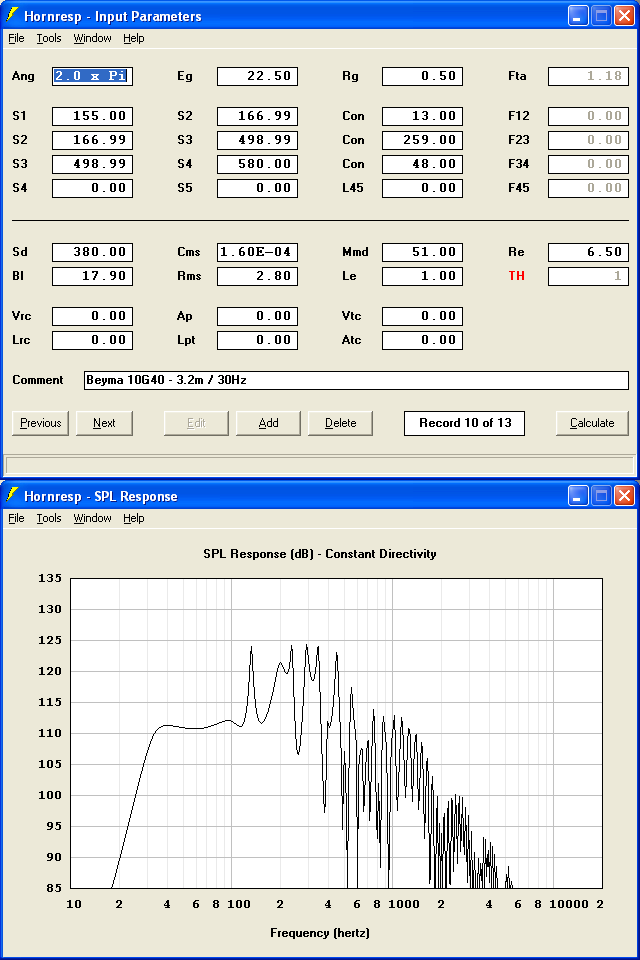

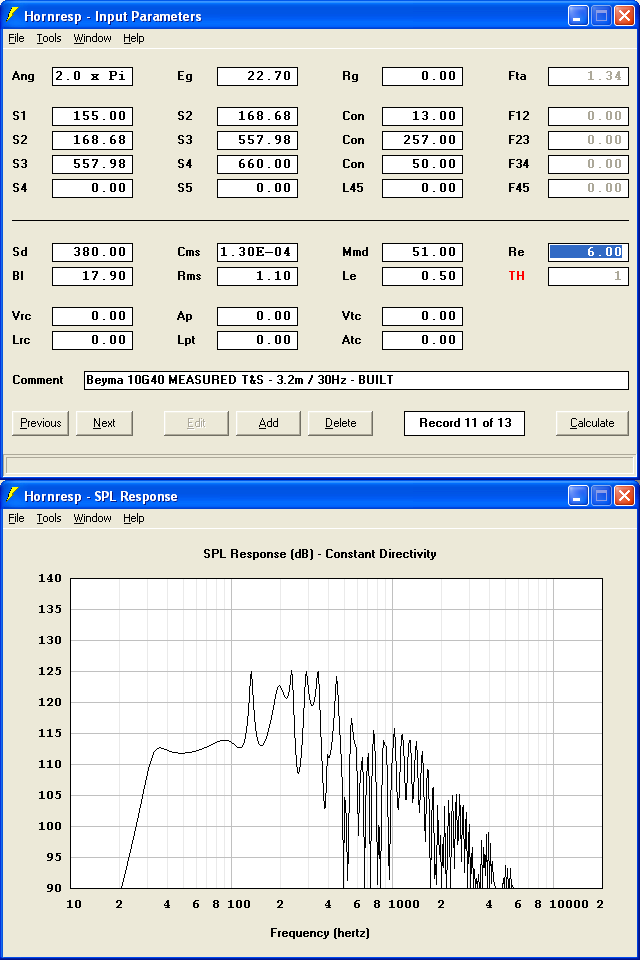

My tapped horn experiment with a Beyma 10G40

Hi tapped horn gurus,

I have been lurking at this thread for while and posted a few times, but last week-end, the time did come to make some saw dust and play some sine sweep...

Just to put things into context, I am looking for a clean sub to cover from 80/100Hz down to as low as possible but realistically lets say 30Hz to go with this project that I have described here.

The only speaker that I have lying around is a Beyma 10G40 that will go later in my center front speaker and I decided to give it a go as it was simulating quite well.

The simulation with the T&S parameters from the specs are as follows.

It is even flatter with an added 2.2mH inductor.

Following advise here, I "measured" the T&S parameters of one of my 10G40 and it models as follows in the same tapped horn (quite similar).

I am putting measured in quotes because:

- I used SpeakerWorkshop measure in free air method

- I did not do the added mass or closed box bit, so do not have Vas

- my speaker stand was not necessarily as rigid as it should be.

Again, it is a bit better with an added inductor.

I then started the build...

Here is how it looks before closing the box.

Where the driver will go...

The driver in place ready to be sealed...

The thing in place for measurement (mic in the mouth)...

Up to this point, I was a happy man...

With the pieces cut to dimension (as we can get from our Home Depot equivalents here in France) it took me 4 hours prompt to fully assemble the thing.

[tbc]

Hi tapped horn gurus,

I have been lurking at this thread for while and posted a few times, but last week-end, the time did come to make some saw dust and play some sine sweep...

Just to put things into context, I am looking for a clean sub to cover from 80/100Hz down to as low as possible but realistically lets say 30Hz to go with this project that I have described here.

The only speaker that I have lying around is a Beyma 10G40 that will go later in my center front speaker and I decided to give it a go as it was simulating quite well.

The simulation with the T&S parameters from the specs are as follows.

It is even flatter with an added 2.2mH inductor.

Following advise here, I "measured" the T&S parameters of one of my 10G40 and it models as follows in the same tapped horn (quite similar).

I am putting measured in quotes because:

- I used SpeakerWorkshop measure in free air method

- I did not do the added mass or closed box bit, so do not have Vas

- my speaker stand was not necessarily as rigid as it should be.

Again, it is a bit better with an added inductor.

I then started the build...

Here is how it looks before closing the box.

Where the driver will go...

The driver in place ready to be sealed...

The thing in place for measurement (mic in the mouth)...

Up to this point, I was a happy man...

With the pieces cut to dimension (as we can get from our Home Depot equivalents here in France) it took me 4 hours prompt to fully assemble the thing.

[tbc]

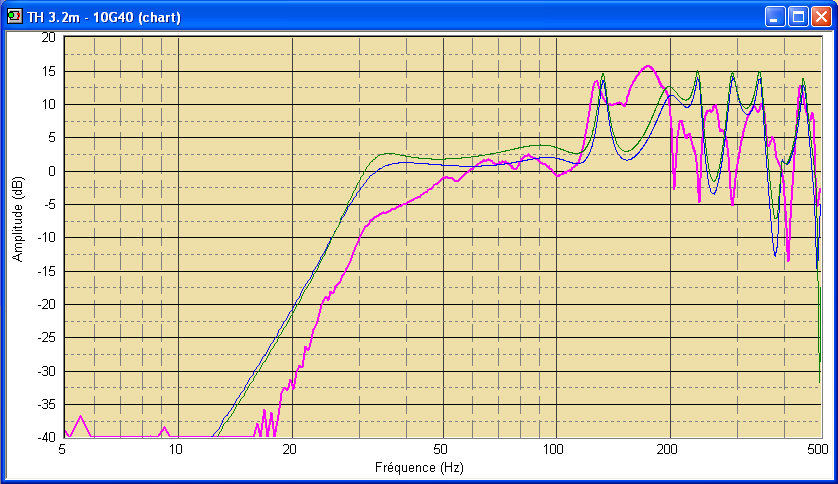

My tapped horn experiment with a Beyma 10G40 - 2

I then started measuring... (not listening, I know it is wrong, but it was late and I was really wishing to measure before living the house for the a week of work away).

First I was quite disapointed with the volume setting I had to apply to get the thing make some noise... It was wired to a modest 60W hifi amp (spare) but I had to push the volume knob to 3/4 to make some "descent" noise (though no idea of the SPL).

This stated, I am not bothered with SPL, I am not a fan of high listening volumes...

Then, I made some measurement with SpeakerWorkshop and there I got really disapointed, well, at list it raises a lot of questions.

Here is a comparison of the measurement and simulations (forget about levels for now).

(pink is measure in the mouth, blue is the HR simulation with spec T&S parameters, green is the HR simulation with measured T&S parameters).

What bothers me for now is that it starts rolling off from 60Hz, when the simulation shows it flat till 30 (and for a sub, it is big difference isn't it ?).

What I would really like to understand and where I need and would really appreciate your helo guys is why this thing does not make the bass it should ?

I have a few ideas but, please fire your comments :

- I used "foam spring joints" to help "airtightness", but cuts were not perfect and there might be some leaks. I doubt though that there are much and that they can make such a difference a modest levels.

- the driver is brand new and not broken in at all... I did not have time to swap with one of the others (they are new as well but had a few hours of listening now as well as about 3x10 hours of 50 / 100 / 200Hz sine signal).

- the measured T&S parameters are not from this driver excatly, but from one of his "brothers"... This does not look like it is making a lot of difference from the factory specs...

I know it is bad, but it was getting late and I died not take the time to wire the tapped horn in my HT amp and try to test it in "real" situation, so I do not even know how it sounds, but 60Hz is not much below than my mains, so I do not know if it will make a difference.

Over to you guys, please comment and criticize, I am all hears and you are more than welcome.

I then started measuring... (not listening, I know it is wrong, but it was late and I was really wishing to measure before living the house for the a week of work away).

First I was quite disapointed with the volume setting I had to apply to get the thing make some noise... It was wired to a modest 60W hifi amp (spare) but I had to push the volume knob to 3/4 to make some "descent" noise (though no idea of the SPL).

This stated, I am not bothered with SPL, I am not a fan of high listening volumes...

Then, I made some measurement with SpeakerWorkshop and there I got really disapointed, well, at list it raises a lot of questions.

Here is a comparison of the measurement and simulations (forget about levels for now).

(pink is measure in the mouth, blue is the HR simulation with spec T&S parameters, green is the HR simulation with measured T&S parameters).

What bothers me for now is that it starts rolling off from 60Hz, when the simulation shows it flat till 30 (and for a sub, it is big difference isn't it ?).

What I would really like to understand and where I need and would really appreciate your helo guys is why this thing does not make the bass it should ?

I have a few ideas but, please fire your comments :

- I used "foam spring joints" to help "airtightness", but cuts were not perfect and there might be some leaks. I doubt though that there are much and that they can make such a difference a modest levels.

- the driver is brand new and not broken in at all... I did not have time to swap with one of the others (they are new as well but had a few hours of listening now as well as about 3x10 hours of 50 / 100 / 200Hz sine signal).

- the measured T&S parameters are not from this driver excatly, but from one of his "brothers"... This does not look like it is making a lot of difference from the factory specs...

I know it is bad, but it was getting late and I died not take the time to wire the tapped horn in my HT amp and try to test it in "real" situation, so I do not even know how it sounds, but 60Hz is not much below than my mains, so I do not know if it will make a difference.

Over to you guys, please comment and criticize, I am all hears and you are more than welcome.

Sabbelbacke said:Befoer going into other details - did you try a ground plane measurement?

Sorry, but what is "ground plane measurement" ?

Doing "free field" measurements gets harder the longer the wavelength ist. One good "trick" to get good results is the ground plane measuerement.

Putting the speaker on a hard surface like a parking space and putting the mik on the floor creates a situation where the floor acts as an acoustical mirror. If there is enough space between mic, box and surrounding objects (cars, buildings), one can easily do good measurements, especially for bass. I have no good online resource on the matter, but the book by Jospeh D'appolitto covers it in detail and it´s the method used by most sub-measurements.

Doing measurements in the horn mouth can have funny effects on the results.. I didn´t try it on a TH but know the effect on frontloaded horns quite good (and because I know measurements like this can be misleading, I never bothered again, always went straight to groundplane).

Putting the speaker on a hard surface like a parking space and putting the mik on the floor creates a situation where the floor acts as an acoustical mirror. If there is enough space between mic, box and surrounding objects (cars, buildings), one can easily do good measurements, especially for bass. I have no good online resource on the matter, but the book by Jospeh D'appolitto covers it in detail and it´s the method used by most sub-measurements.

Doing measurements in the horn mouth can have funny effects on the results.. I didn´t try it on a TH but know the effect on frontloaded horns quite good (and because I know measurements like this can be misleading, I never bothered again, always went straight to groundplane).

jm_kzo's Beyma 10G40 TH

The manufacturer spec states a Vas of 33 liters, do you think it could be too high ?

What about breaking in the driver ?

These PA things do havee stiff suspensions and everybody says that they still evolve after tens of hours if not hundreds...

With regards to pinhole leaks, they are definitely a few of them... I did not use glue because I wished to be able to dismantle the thing and try different things, but I might have to now...

Any other suggestion ?

just a guy said:...if it's (too) high vas causing this problem there's not much you can do.

The manufacturer spec states a Vas of 33 liters, do you think it could be too high ?

What about breaking in the driver ?

These PA things do havee stiff suspensions and everybody says that they still evolve after tens of hours if not hundreds...

With regards to pinhole leaks, they are definitely a few of them... I did not use glue because I wished to be able to dismantle the thing and try different things, but I might have to now...

Any other suggestion ?

@ jm_kzo

Can you measure impedance? That may help identify leaks.

Some more questions:

How did you seal the top of the cabinet?

Is your microphone/preamp/measuring system accurate below 60 Hz?

Are you using any sort of response weighting in your mic preamp?

Are you measuring indoors?

Room response can really mess up measurements. Perhaps loading the mouth of the Horn against a wall or into a corner will bring the low end back.

Perhaps you could try measuring with FreqRespPlot or a another free swept-sine measurement software as a check of Speaker Workshop?

FreqRespPlot (in French)

There is an English version of the helpfile and software available too.

Can you measure impedance? That may help identify leaks.

Some more questions:

How did you seal the top of the cabinet?

Is your microphone/preamp/measuring system accurate below 60 Hz?

Are you using any sort of response weighting in your mic preamp?

Are you measuring indoors?

Room response can really mess up measurements. Perhaps loading the mouth of the Horn against a wall or into a corner will bring the low end back.

Perhaps you could try measuring with FreqRespPlot or a another free swept-sine measurement software as a check of Speaker Workshop?

FreqRespPlot (in French)

There is an English version of the helpfile and software available too.

- Home

- Loudspeakers

- Subwoofers

- Collaborative Tapped horn project