If I recall correctly, you've never built a loudspeaker before.

[...]

What if you stick to DIY'ing everything else about your home, yard and listening environment, but leave the speaker building to that guy named Danley

I was thinking something similar, but I still favour DIY (this is a DIY site after all)... so my advice is to build some smaller stuff / other parts of the system before deciding on the concrete sub. Get some personal, practical building + listening knowledge before making decisions that are indeed set in stone.

For example, DIY the midbass and HF parts of the system first (from 20kHz to <100Hz). It will cost you nothing if you re-use those parts in the final build, and it might tell you a lot.

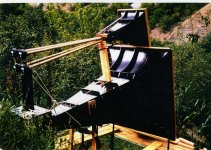

...and build an ugly, temporary sub (see link + note below). Put it close to your listening position so it can easily keep up with the horns.

...and listen.

See what power levels you like. Calculate from that how much grunt you'll need in the final build. Maybe you'll find that 10 watts is deafening.

Try different high pass points on the sub. Get someone else to change the settings for you (a blind test). Maybe you'll find that, when listening to your 50 favourite songs, you cannot tell whether the sub is being high passed at 15Hz or 25Hz.

If that was the case, you could ~halve the size of your planned horn.

-----

Tapped Horn Experiments

These 18Hz tapped horns (or similar, up to 240cm long) look like an easy build. The panels are big, and simple, and there aren't many cuts required.

This part of the experiment would be almost free: When done, tear the box apart and re-use the plywood to brace the forms for pouring your concrete.

Equation 9.33 within the LLB3.PDF file seems to correlate with both the Hornresp program, and the graph you posted on #1187.

Hornresp currently uses the more general equation 9.32.

HOWEVER...

The ongoing discussion on distortion has prompted me to look into things a little more deeply.

Interestingly, it would appear that the Beranek formula is incorrect, and that the distortion percentages produced using the equation need to be multiplied by a factor of 1 / Sqrt(2). The more recent book by Beranek and Mellow shows a slightly modified formula with the factor added. The chart given in Olson's "Acoustical Engineering" is also consistent with the results produced using the Beranek and Mellow formula.

Sanity check:

Original Beranek Chart:

Distortion = 14% when throat intensity = 0.7 W/cm2 and f/fc = 10

Later Beranek and Mellow Chart:

Distortion = 10% when throat intensity = 0.7 W/cm2 and f/fc = 10

Olson Chart:

Distortion = 10% when throat intensity = 0.7 W/cm2 and f/fc = 10

Hornresp needs to be updated accordingly.

Last edited:

I've read ALL 120 pages.

It's a long thread. . . .

I've built several home-audio systems. Mostly bass-reflex 3-way systems. What's really driving this project isn't even music. It's my stupid signal generator that I use for breaking in speakers & testing my finished products. I enjoy sweeping the signal generator down for the first time - watching the speaker cone come to a stop, while massive bass resonates from the port (which is indicative of a good tune). But below the tune frequency, the speaker unloads completely, and the bass cuts out like a switch. Sealed boxes are ok, I guess. But you need an entire wall of them to pump out low frequencies with any authority.

The bass horn will go lower, and lower, and then even lower - without any perceived reduction in SPL - down to 15 Hz! I just want to hear it - to stand in front of it and sweep it down to fc. . . . The speakers you've linked, while I'm sure would sound simply fabulous, will not drive through the bottom octave with any authority. Don't get me wrong, I want to listen to music on my horn system also. But that first sweep with a signal generator will give me the satisfaction I'm seeking. It will make the entire project worthwhile.

On the topic of large and unnecessary things - below are pictures of my newest hobby lathe. It's 18 feet between centers, weighs about 25,000 pounds, and has a 40 horsepower spindle motor. I'm really stoked about this lathe - I had to share. . .

My 'office' is not big enough ....

The acoustic side of your horn design is virtually a no risk proposition because you are prepared to not cheat on horn size, and now you are looking at an adequate driver complement. Still would like to see you use M-Force drivers. The risks are strictly architectural and construction related.

Once your ears (and body) have experienced real bass reproduction (or a live organ performance) you will never go back to the wimpy stuff. I have two big 18" Velodynes and want a lot more.

….. so for my recent acquisition, I had to settle for this.

Not yet, but it will be if you see this project through to a successful end.It's a long thread. . . .

The acoustic side of your horn design is virtually a no risk proposition because you are prepared to not cheat on horn size, and now you are looking at an adequate driver complement. Still would like to see you use M-Force drivers. The risks are strictly architectural and construction related.

The bass horn will go lower, and lower, and then even lower - without any perceived reduction in SPL - down to 15 Hz! I just want to hear it - to stand in front of it and sweep it down to fc. . . . The speakers you've linked, while I'm sure would sound simply fabulous, will not drive through the bottom octave with any authority. Don't get me wrong, I want to listen to music on my horn system also. But that first sweep with a signal generator will give me the satisfaction I'm seeking. It will make the entire project worthwhile.

Once your ears (and body) have experienced real bass reproduction (or a live organ performance) you will never go back to the wimpy stuff. I have two big 18" Velodynes and want a lot more.

On the topic of large and unnecessary things - below are pictures of my newest hobby lathe. It's 18 feet between centers, weighs about 25,000 pounds, and has a 40 horsepower spindle motor. I'm really stoked about this lathe - I had to share. . .

….. so for my recent acquisition, I had to settle for this.

Attachments

Last edited:

Horn Nonlinear Distortion Revisited

The attached files contain and excerpt form the more recent work of Beranek and Mellow concerning Nonlinear Distortion in horns that was referenced by David McBean earlier in this thread.

In the virtual equation 9.85a set P1 = PT*[cosh(m*x/2)+T*sinh(m*x/2)] and PT = [(It*ρ0*c)]^(1/2)

then equation 9.86 can be recast to cover the entire Salmon family of horns (Exponential Included), i.e.:

{50*(γ+1) / (γ*P0)}*{[(It*ρ0*c)/2)]^(1/2)}*{ƒ/ƒc}*{1–[1/[cosh(m*x/2) + T*sinh(m*x/2)]]}

Notes:

x - length of horn

m - flare constant

= (4*pi*ƒc)/c

The effect of back-wave propagation is ignored here.

Regards,

WHG

The attached files contain and excerpt form the more recent work of Beranek and Mellow concerning Nonlinear Distortion in horns that was referenced by David McBean earlier in this thread.

In the virtual equation 9.85a set P1 = PT*[cosh(m*x/2)+T*sinh(m*x/2)] and PT = [(It*ρ0*c)]^(1/2)

then equation 9.86 can be recast to cover the entire Salmon family of horns (Exponential Included), i.e.:

{50*(γ+1) / (γ*P0)}*{[(It*ρ0*c)/2)]^(1/2)}*{ƒ/ƒc}*{1–[1/[cosh(m*x/2) + T*sinh(m*x/2)]]}

Notes:

x - length of horn

m - flare constant

= (4*pi*ƒc)/c

The effect of back-wave propagation is ignored here.

Regards,

WHG

Attachments

Last edited:

I'm narrowing down on my horn design. If I stick with aspect ratio I have in mind, the horn mouth will be 18 feet wide x 12.5 feet tall (rectangular).

Here's an unresolved problem - if I build a single horn, how do I get a mono signal from a stereo source (i.e. CD, DVD, satellite radio, etc)? Do I need a mixer? Or do I simply run one of the channels into the horn, and hope the recording is mono from 150 Hz and down? Or what about using an even number of drivers in the horn, and driving half with one channel, and the other half with the other channel - then let the horn's front chamber do the mixing (seems Hill-Billy). Stereo separation is said to be audible above 80 Hz. There's almost an entire octave between 80 and 150 Hz. I feel like I'm making a very significant compromise with a mono horn.

Another option is to revisit the stereo horn - aka side by side 15 Hz horns with a common center-divider wall (so as to minimize comb-filtering). I'd use the same aspect ratio, for an overall horn mouth 36 foot wide x 12.5 foot tall. My shop doors (pictured above) are 16 foot wide x 14 foot tall. So a pair of stereo horns would roughly be the size of my garage doors, less the center divider. I was doing some geometry checks with the aspect ratio I've selected. A 6 foot tall person could walk about 20 feet into the horn before hitting one's head. It's the last 10 feet of the horn that gets really massive. I want to build the horn (or horns) into the hillside, and backfill dirt over them - to conceal as much as I can within the landscape. The horn roof will require the most reinforcement - likely cast 10 or 12 inches thick.

Most DSPs (digital signal processors) have provisions for summing stereo LF channels.Here's an unresolved problem - if I build a single horn, how do I get a mono signal from a stereo source (i.e. CD, DVD, satellite radio, etc)?

Most DSPs (digital signal processors) have provisions for summing stereo LF channels.

That would be the best solution. I need to delay the mains by roughly 0.030 seconds to time-align the horn with the rest of the system - which requires a DSP.

I still feel like I'm making a compromise building a mono bass horn. Which is more desirable? Near-zero comb-filtering of bass frequencies in exchange for non-existent stereo separation between 80 Hz and the horn crossover frequency - or true stereo horns, with some degree of comb-filtering?

Error

https://www.diyaudio.com/forums/subwoofers/119854-hornresp-902.html#post5658874

See here for correction:The attached files contain and excerpt form the more recent work of Beranek and Mellow concerning Nonlinear Distortion in horns that was referenced by David McBean earlier in this thread.

In the virtual equation 9.85a set P1 = PT*[cosh(m*x/2)+T*sinh(m*x/2)] and PT = [(It*ρ0*c)]^(1/2)

then equation 9.86 can be recast to cover the entire Salmon family of horns (Exponential Included), i.e.:

{50*(γ+1) / (γ*P0)}*{[(It*ρ0*c)/2)]^(1/2)}*{ƒ/ƒc}*{1–[1/[cosh(m*x/2) + T*sinh(m*x/2)]]}

Notes:

x - length of horn

m - flare constant

= (4*pi*ƒc)/c

The effect of back-wave propagation is ignored here.

Regards,

WHG

https://www.diyaudio.com/forums/subwoofers/119854-hornresp-902.html#post5658874

Option

Implement an asymmetric crossover that focuses more of the 50 - 90 hertz energy into the satellites where some residual directional information may still reside. This will require extra beef in the mid-bass units but this tack will certainly be less expensive than the cost of two mega-bass horns. WHG

That would be the best solution. I need to delay the mains by roughly 0.030 seconds to time-align the horn with the rest of the system - which requires a DSP.

I still feel like I'm making a compromise building a mono bass horn. Which is more desirable? Near-zero comb-filtering of bass frequencies in exchange for non-existent stereo separation between 80 Hz and the horn crossover frequency - or true stereo horns, with some degree of comb-filtering?

Implement an asymmetric crossover that focuses more of the 50 - 90 hertz energy into the satellites where some residual directional information may still reside. This will require extra beef in the mid-bass units but this tack will certainly be less expensive than the cost of two mega-bass horns. WHG

Hillside Options

For hillside construction you could sculpt undisturbed earth, line it with plastic and use it as the bottom of your form. After pour and set excavate the core and use it for backfill and then pour the floor slab between the footers. The horn body would of course, be a self supporting arch shape in section.

Otherwise for a rectangular section horn, to

avoid the heavy roof pour, use two additional vane walls to carry the long span load to ground. On 4-1/2 ft centers at the mouth, they will be acoustically transparent. Post tension the roof slab if necessary.

Whether you burry it or not, seismically the horn structure is still "like a box floating on water".

WHG

I'm narrowing down on my horn design. If I stick with aspect ratio I have in mind, the horn mouth will be 18 feet wide x 12.5 feet tall (rectangular).

>snip<

Another option is to revisit the stereo horn - aka side by side 15 Hz horns with a common center-divider wall (so as to minimize comb-filtering). I'd use the same aspect ratio, for an overall horn mouth 36 foot wide x 12.5 foot tall. My shop doors (pictured above) are 16 foot wide x 14 foot tall. So a pair of stereo horns would roughly be the size of my garage doors, less the center divider. I was doing some geometry checks with the aspect ratio I've selected. A 6 foot tall person could walk about 20 feet into the horn before hitting one's head. It's the last 10 feet of the horn that gets really massive. I want to build the horn (or horns) into the hillside, and backfill dirt over them - to conceal as much as I can within the landscape. The horn roof will require the most reinforcement - likely cast 10 or 12 inches thick.

For hillside construction you could sculpt undisturbed earth, line it with plastic and use it as the bottom of your form. After pour and set excavate the core and use it for backfill and then pour the floor slab between the footers. The horn body would of course, be a self supporting arch shape in section.

Otherwise for a rectangular section horn, to

avoid the heavy roof pour, use two additional vane walls to carry the long span load to ground. On 4-1/2 ft centers at the mouth, they will be acoustically transparent. Post tension the roof slab if necessary.

Whether you burry it or not, seismically the horn structure is still "like a box floating on water".

WHG

A typical 7.0 earthquake in our area produces 1 G-Force lateral acceleration @ 1 Hz. We get this size quake every 30 to 35 years like clockwork (it happens to be the design-acceleration requirement for structures in my area).

The horn will be much more rigid than a concrete parking garage, and parking garages do just fine in 7.0 earthquakes. If the big one hits however (Cascadia fault-line), all bets are off. . .

A decommissioned Navy installation in my area has large underground munitions bunkers. They they look like a gentle mounds of dirt with a concrete wall cut into the side. There's a loading dock platform, and a large door cast into the wall. These have been through 3 large earthquakes, and are holding up just fine. There still used to this day for various storage. One has actually been converted into a church/recreation center.

I have a hillside, thus there won't be a pronounced mound of dirt coving the horn. What I don't want to see is giant concrete horns sitting on top of the ground. . .

I'll sketch up a conceptual construction drawing, and post it this evening.

The horn will be much more rigid than a concrete parking garage, and parking garages do just fine in 7.0 earthquakes. If the big one hits however (Cascadia fault-line), all bets are off. . .

A decommissioned Navy installation in my area has large underground munitions bunkers. They they look like a gentle mounds of dirt with a concrete wall cut into the side. There's a loading dock platform, and a large door cast into the wall. These have been through 3 large earthquakes, and are holding up just fine. There still used to this day for various storage. One has actually been converted into a church/recreation center.

I have a hillside, thus there won't be a pronounced mound of dirt coving the horn. What I don't want to see is giant concrete horns sitting on top of the ground. . .

I'll sketch up a conceptual construction drawing, and post it this evening.

This is one of the most interesting and compelling audio projects I've yet come across here! Must confess to having only finished reading the first few hundred posts (and will, I promise, resume in a few minutes and read them all) when I just HAD to cheat to the end to see if it/they exist(s) yet.

If somebody hasn't already mentioned it, I'll be mighty surprised if there aren't at least a few other readers here who'd want to put seeing/hearing this beast on their bucket list. It is definitely on mine. Hope you don't have to pave a parking lot and designate certain-days-only!

Oh, and congrats on the lathe -- now you can build a Much Bigger cannon.

Regards,

Rick

If somebody hasn't already mentioned it, I'll be mighty surprised if there aren't at least a few other readers here who'd want to put seeing/hearing this beast on their bucket list. It is definitely on mine. Hope you don't have to pave a parking lot and designate certain-days-only!

Oh, and congrats on the lathe -- now you can build a Much Bigger cannon.

Regards,

Rick

echos

Here is a project similar to yours.

They used concrete shell construction essentially above ground.

I have attached some files for immediate viewing here.

A lot more may be found at the following URL.

Echos 2015 - The acoustic system

Note the waveguides on the tweeter horn used for time alignment.

Regards,

WHG

Here is a project similar to yours.

They used concrete shell construction essentially above ground.

I have attached some files for immediate viewing here.

A lot more may be found at the following URL.

Echos 2015 - The acoustic system

Note the waveguides on the tweeter horn used for time alignment.

Regards,

WHG

Attachments

-

ThroatEntry.jpg74.6 KB · Views: 156

ThroatEntry.jpg74.6 KB · Views: 156 -

ThroatManifold.jpg78.3 KB · Views: 223

ThroatManifold.jpg78.3 KB · Views: 223 -

DriverCluster.jpg71.8 KB · Views: 194

DriverCluster.jpg71.8 KB · Views: 194 -

HornSpec.jpg54.7 KB · Views: 258

HornSpec.jpg54.7 KB · Views: 258 -

NeckConstruction.jpg113.1 KB · Views: 262

NeckConstruction.jpg113.1 KB · Views: 262 -

BellConstruction.jpg145.6 KB · Views: 283

BellConstruction.jpg145.6 KB · Views: 283 -

HornPlacement.jpg142 KB · Views: 259

HornPlacement.jpg142 KB · Views: 259 -

FinishedHorn.jpg144.3 KB · Views: 254

FinishedHorn.jpg144.3 KB · Views: 254 -

échos.pdf525.5 KB · Views: 64

-

SateliteHorns.jpg270 KB · Views: 175

SateliteHorns.jpg270 KB · Views: 175

Last edited:

A typical 7.0 earthquake in our area produces 1 G-Force lateral acceleration @ 1 Hz. We get this size quake every 30 to 35 years like clockwork (it happens to be the design-acceleration requirement for structures in my area).

The horn will be much more rigid than a concrete parking garage, and parking garages do just fine in 7.0 earthquakes. If the big one hits however (Cascadia fault-line), all bets are off. . .

A decommissioned Navy installation in my area has large underground munitions bunkers. They they look like a gentle mounds of dirt with a concrete wall cut into the side. There's a loading dock platform, and a large door cast into the wall. These have been through 3 large earthquakes, and are holding up just fine. There still used to this day for various storage. One has actually been converted into a church/recreation center.

I have a hillside, thus there won't be a pronounced mound of dirt coving the horn. What I don't want to see is giant concrete horns sitting on top of the ground. . .

I'll sketch up a conceptual construction drawing, and post it this evening.

well this year has give me some extra time and i found this thread... interesting to say the least, wish i could have been working on a project and not just reading about this one. 1532 days since it started

entropy455 have you built anything yet? i can understand because i have some audio dreams that are twice as old easily. Ive spent time learning then did a full gut and remodel of a big house, then had a daughter and now i have to relearn things allover again.

i hope 2021 is your year. lets see that conceptual drawing you promised.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Concrete Bass Horn Design Question