Hmm, that's pretty cool, however the path length for each driver would be different. If you could manage to get the rear of the ppsl area to open into the horn at the same distance between the drivers and it would be perfect

Edit, Im not sure if this distance matters much (I assume phase issues) but I would prefer to have them the same distance than to risk it and see what happens..

Furthermore I am not sure if you need to account for the distance to the drivers within the slot itself or if this has been done (minor distance but still!)

Edit, Im not sure if this distance matters much (I assume phase issues) but I would prefer to have them the same distance than to risk it and see what happens..

Furthermore I am not sure if you need to account for the distance to the drivers within the slot itself or if this has been done (minor distance but still!)

Last edited:

Hi reminence,

I'm not certain that much will be gained from the PPSL driver mounting in this enclosure type. The wavelength of the frequencies of interest are just way too long for the path length difference - in the length of the path from the S2 side of the drivers to the common line path - to matter. If anything this area might just work like a coupling chamber. I was a bit surprised that the gross volume went up to 302.8 L.

I think both of these would work well, and I'd go with the simpler construction, but, just one way to find out, isn't there?

Regards,

I'm not certain that much will be gained from the PPSL driver mounting in this enclosure type. The wavelength of the frequencies of interest are just way too long for the path length difference - in the length of the path from the S2 side of the drivers to the common line path - to matter. If anything this area might just work like a coupling chamber. I was a bit surprised that the gross volume went up to 302.8 L.

I think both of these would work well, and I'd go with the simpler construction, but, just one way to find out, isn't there?

Regards,

Last edited:

whats the box tuned to? is there a response plot?

tb46, what do you mean by both, do you mean ppsl vs your older design with just pp?

The reason I am a fan of ppsl is the lack of distortion, since tapped horns/t-tqwt still have a side of the driver near the mouth, the distortion from that side of the speaker will be heard (educated guess).

Upon reading the differences in horn vs tapped horn many have said that because of this that distortion can be heard in taped horns a lot more than traditional horns.

Also I read somewhere that ppsl has even less audible distortion than horns and that some hifi enthusiasts replaced their tapped horns with ppsl designs.

I do know that it could be minimized a lot by having a similar design to your first but both speakers in opposite directions yet this doesn't not yield as much distortion reduction as does ppsl.

tb46, what do you mean by both, do you mean ppsl vs your older design with just pp?

The reason I am a fan of ppsl is the lack of distortion, since tapped horns/t-tqwt still have a side of the driver near the mouth, the distortion from that side of the speaker will be heard (educated guess).

Upon reading the differences in horn vs tapped horn many have said that because of this that distortion can be heard in taped horns a lot more than traditional horns.

Also I read somewhere that ppsl has even less audible distortion than horns and that some hifi enthusiasts replaced their tapped horns with ppsl designs.

I do know that it could be minimized a lot by having a similar design to your first but both speakers in opposite directions yet this doesn't not yield as much distortion reduction as does ppsl.

Last edited:

I like tite bond yellow wood glue much much better than pl glues. It cleans up much much easier than pl, sands away much quicker etc.

BUT, it just won't fill any gaps you have, so your cutting and measuring must be pretty precise.

Doesn't sound like its something I would want, I would much prefer to do a good job at making it work and sound good over the aesthetics at this stage but thanks.

Any other suggestions?

I am just worried that most glues wont do nearly as good a job as this pl premium which is not available here.

What do you use col?

Last edited:

Liquid Nails left to dry in the aussie sun will suffice. Just make sure you have a damp sponge to wipe off the excess.

Will the excess cause damage or just make it look bad, Internally I would apply it rather liberally which is why I ask.

Oh and I know most speaker building sites state to use screws and glue but its the glue that really holds it together and the screws only keep it in place.

Other than that, thanks

Will the excess cause damage or just make it look bad, Internally I would apply it rather liberally which is why I ask.

Oh and I know most speaker building sites state to use screws and glue but its the glue that really holds it together and the screws only keep it in place.

Other than that, thanks

I try not to use screws, Iv'e got a good selection of clamps though, supercheapauto has a good range that are not to expensive, corner clamps are very handy and the frame straps too. If I'm not to worried about the appearance I use my air nailer.

Liquid Nails is water washable, you can wipe off the excess with a damp sponge as it oozes out of the gaps. Iv'e assembled heaps of cabs with it, haven't had a panel come loose yet.

col.

Post #44

Hi reminence,

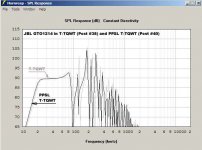

With both I ment the T-TQWT from Post #38 and the PPSL T-TQWT from Post #40.

I was under the mistaken impression that you were using Hornresp, that way you could get all the data/graphs you want for both enclosures. You could just type in the input screens that I provided, and look around in Hornresp; if you do that don't get confused with the Hornresp impulse response in graph form, it does not represent the impulse response of the partially stuffed enclosure, and does not have any provision for representing the effect of low-cut and high-cut filters; use the impulse response spectrogram instead.

From Post #38: "...The driver that sits further away from the mouth could be reversed for improved distortion cancelling, but that will require a 3/4"-1" shim, and it will restrict the duct, so it would have to be tried. ..."

As to the construction: personally I use something like Titebond glue with a nail gun and clamps/straps. The nail gun makes positioning easy. Sometimes I'll use a bisquit joiner for more difficult, or stressed, corners. Col's advice sounds fine too.

Whatever you do, make sure that you can get the drivers in and out, and that you can modify the filling/stuffing easily. For the PPSL that will be more difficult. I did obviously not draw all the fine details for cleats, or blocking, etc....

Regards,

Hi reminence,

With both I ment the T-TQWT from Post #38 and the PPSL T-TQWT from Post #40.

I was under the mistaken impression that you were using Hornresp, that way you could get all the data/graphs you want for both enclosures. You could just type in the input screens that I provided, and look around in Hornresp; if you do that don't get confused with the Hornresp impulse response in graph form, it does not represent the impulse response of the partially stuffed enclosure, and does not have any provision for representing the effect of low-cut and high-cut filters; use the impulse response spectrogram instead.

From Post #38: "...The driver that sits further away from the mouth could be reversed for improved distortion cancelling, but that will require a 3/4"-1" shim, and it will restrict the duct, so it would have to be tried. ..."

As to the construction: personally I use something like Titebond glue with a nail gun and clamps/straps. The nail gun makes positioning easy. Sometimes I'll use a bisquit joiner for more difficult, or stressed, corners. Col's advice sounds fine too.

Whatever you do, make sure that you can get the drivers in and out, and that you can modify the filling/stuffing easily. For the PPSL that will be more difficult. I did obviously not draw all the fine details for cleats, or blocking, etc....

Regards,

Attachments

Sorry tb46, I have had much trouble downloading hornresp and haven't used it before, though not for a lack of trying.

It seams to me that getting at the drivers and throat stuffing will be near impossible for both designs. I guess I was hopping to just seal the box and be done with the fiddling. My studio is residential and I am a very courteous neighbour so I doubt it will ever be pushed hard enough to do driver damage.

Also I have never build a speaker before so these "cleats and blocking" im pretty unaware of.

It seams to me that getting at the drivers and throat stuffing will be near impossible for both designs. I guess I was hopping to just seal the box and be done with the fiddling. My studio is residential and I am a very courteous neighbour so I doubt it will ever be pushed hard enough to do driver damage.

Also I have never build a speaker before so these "cleats and blocking" im pretty unaware of.

Hi reminence,

Go with the T-TQWT (Post #38), much easier build, much easier access. Just a few pointers:

- make the front baffle removable (!), that'll give you access for easy speaker mounting (use T-nuts or hurricane nuts on the back of the speaker baffle)

- provide access to the sections that need stuffing if you feel like you would like to fiddle with it; or, just apply about 1 lb (16 oz.) evenly as indicated in the drawing, and leave it as that. Maybe bjorno can help with a more scientific explanation.

- with cleats and blocking I'm just referring to corner reinforcement.

- you also may add some board to board bracing as DrDyna did here, Post #21:

http://www.diyaudio.com/forums/subwoofers/188283-fiddling-hornresp-peerless-831759-a-3.html

- if you add braces, cut holes in the braces to reduce their acoustic influence (I'll try to find a better picture for you, or maybe somebody else can provide one)

Take a good look at how ODougbo solved his problems:

http://www.diyaudio.com/forums/subwoofers/203345-isobaric-less-then-20-a.html

He even retrofitted access holes in a box he had already glued together (Post #125), just a lot of ways of doing all this.

If your studio is residential, you'll get more than enough output out of even one of the T-TQWT.

Regards,

Go with the T-TQWT (Post #38), much easier build, much easier access. Just a few pointers:

- make the front baffle removable (!), that'll give you access for easy speaker mounting (use T-nuts or hurricane nuts on the back of the speaker baffle)

- provide access to the sections that need stuffing if you feel like you would like to fiddle with it; or, just apply about 1 lb (16 oz.) evenly as indicated in the drawing, and leave it as that. Maybe bjorno can help with a more scientific explanation.

- with cleats and blocking I'm just referring to corner reinforcement.

- you also may add some board to board bracing as DrDyna did here, Post #21:

http://www.diyaudio.com/forums/subwoofers/188283-fiddling-hornresp-peerless-831759-a-3.html

- if you add braces, cut holes in the braces to reduce their acoustic influence (I'll try to find a better picture for you, or maybe somebody else can provide one)

Take a good look at how ODougbo solved his problems:

http://www.diyaudio.com/forums/subwoofers/203345-isobaric-less-then-20-a.html

He even retrofitted access holes in a box he had already glued together (Post #125), just a lot of ways of doing all this.

If your studio is residential, you'll get more than enough output out of even one of the T-TQWT.

Regards,

Last edited:

The Ande 15" LB15-1 will in fact fit Dag Johansen's 40 Hz TH even better than the Eminence Lab-15 for about half the price. Dag's thread is here:

http://www.diyaudio.com/forums/subwoofers/190909-40hz-th.html .

/Erling

http://www.diyaudio.com/forums/subwoofers/190909-40hz-th.html .

/Erling

That sounds awesome tb46.

By baffle do you mean the sheet directly in front of both drivers? that sheet seams to be the best to remove for access but I'm not sure if it will effect the stability of the mouth nor how to make it removable, maybe rubber seal and lots of bolts/screws.

as for damping i have read the cheats way is to do it near the end of the throat, possible on the corner away from the mouth but as to what damping material to use im not sure what we have over here.

Thanks skorpion for the insight into that driver, Dag's horn was an option before but probably no longer, even for the PA build I will do later on. Since I will no longer be constrained by the same limited weight and dimensions I would probably aim for a 30hz box of larger size but that's for way after this build.

By baffle do you mean the sheet directly in front of both drivers? that sheet seams to be the best to remove for access but I'm not sure if it will effect the stability of the mouth nor how to make it removable, maybe rubber seal and lots of bolts/screws.

as for damping i have read the cheats way is to do it near the end of the throat, possible on the corner away from the mouth but as to what damping material to use im not sure what we have over here.

Thanks skorpion for the insight into that driver, Dag's horn was an option before but probably no longer, even for the PA build I will do later on. Since I will no longer be constrained by the same limited weight and dimensions I would probably aim for a 30hz box of larger size but that's for way after this build.

are you refering to this: http://www.diyaudio.com/forums/subwoofers/143714-lab12-tapped-horn.html

as I was looking at that but with some driver available in aus. If so how good is the box i have read it gets down to 18hz at its rolloff?

Eminence LAB12

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 20-30hz tapped horn for studio with ande drivers