solder?Jpin -> Solder to board -> bend over the short end.

I thought from the top side pics, that you were using perf board.

Thanks again.

solder?

I thought from the top side pics, that you were using perf board.

Thanks again.

I am using Dot Board. Assembling is a breeze...

Attachments

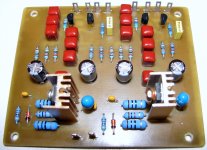

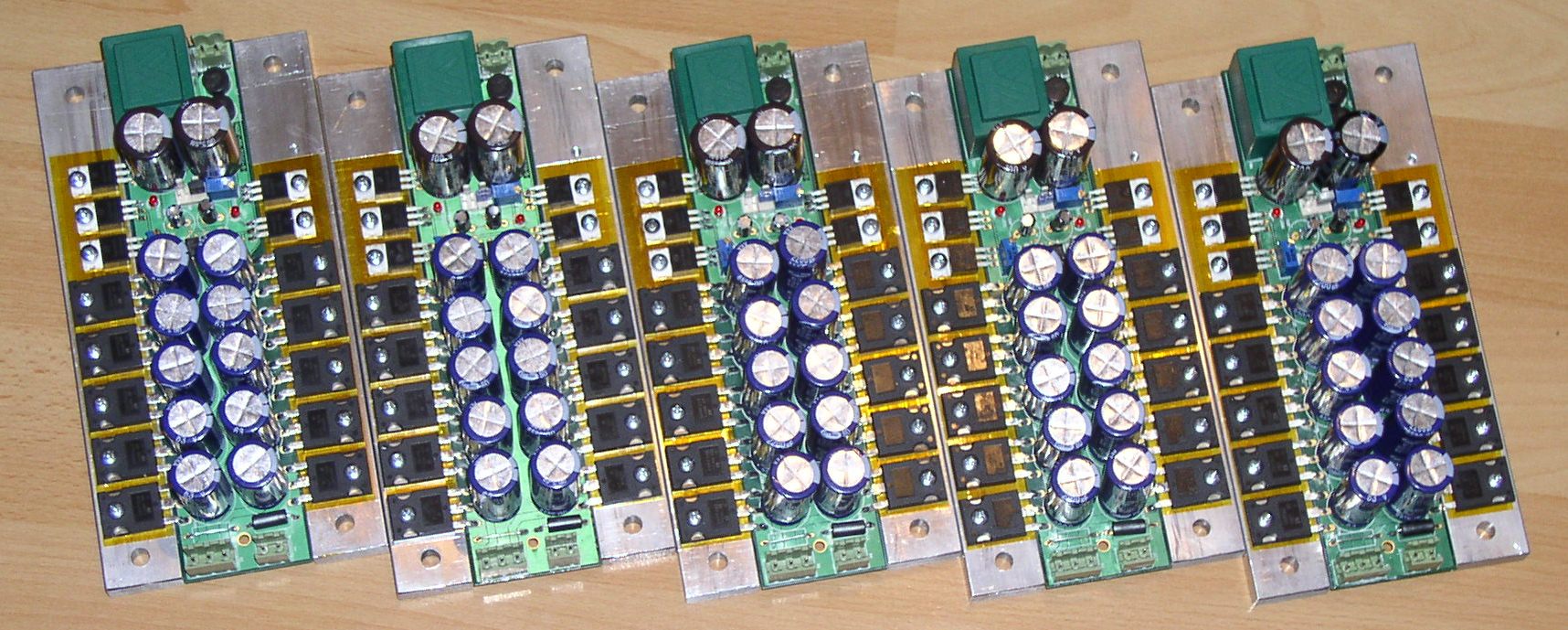

My JFET_CD out PCB ..... not tested , just assembled

Attachments

Last edited:

My JFET_CD out PCB ..... not tested , just assembled

Nice job Alex...

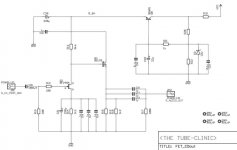

Nice but look like si-bi radio station =)ok, so here is mine...

What design is that exactly?ok, so here is mine...

LOL thanks mate, 'si-bi radio station', that is a good one. You got it all wrong, it is a Toaster...

The basic design started out as a HPA by GMarsh and I just added a few extra features to it. Eventually I added more and more stuff until I run out of room. Features such as IR, servo volume control, a lot more inputs, LCD, VU Meter, QTouch ect.

Cheers

The basic design started out as a HPA by GMarsh and I just added a few extra features to it. Eventually I added more and more stuff until I run out of room. Features such as IR, servo volume control, a lot more inputs, LCD, VU Meter, QTouch ect.

Cheers

Attachments

Last edited:

Banned

Joined 2002

LOL thanks mate, 'si-bi radio station', that is a good one. You got it all wrong, it is a Toaster...

The basic design started out as a HPA by GMarsh and I just added a few extra features to it. Eventually I added more and more stuff until I run out of room.

Such as IR, servo volume control, a lot more inputs, LCD, VU Meter, QTouch ect.

Cheers

I want one

LOL thanks mate, 'si-bi radio station', that is a good one. You got it all wrong, it is a Toaster...

The basic design started out as a HPA by GMarsh and I just added a few extra features to it. Eventually I added more and more stuff until I run out of room. Features such as IR, servo volume control, a lot more inputs, LCD, VU Meter, QTouch ect.

Cheers

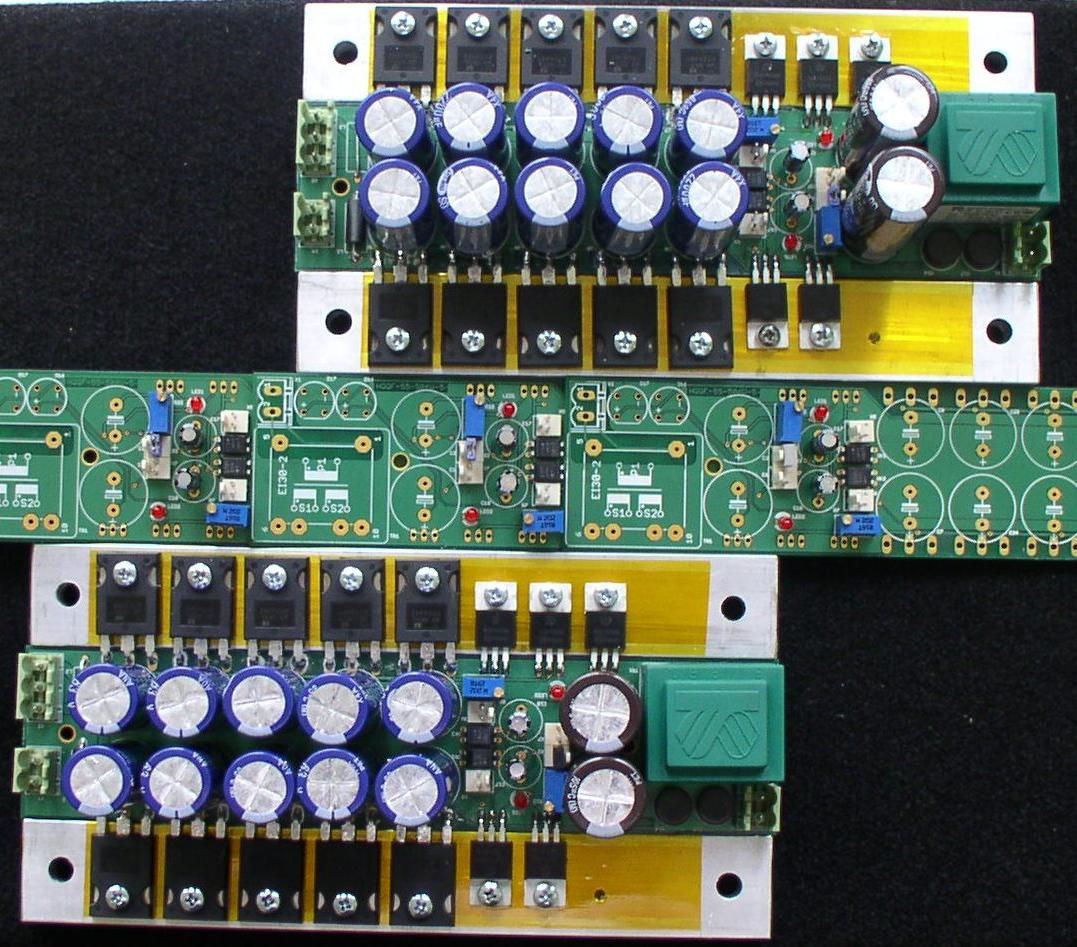

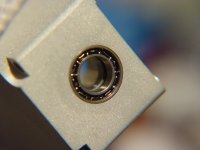

Nice looking volume control unit (2nd picture). I have seen for first time. Looking at the foot-print on the PCB (1st picture) it seems to be a motorized volume pot. Its brand? Thanks for any information.

Last edited:

Nice looking volume control unit (2nd picture). I have seen for first time. Looking at the foot-print on the PCB (1st picture) it seems to be a motorized volume pot. Its brand? Thanks for any information.

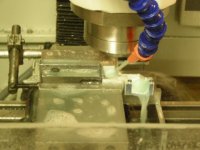

Thanks fotios, yes, it is motorized. The quadrature encoder is made by Bourns and the Aluminum (7075 alloy) is made by ALCOA and machined to my spec.

Of course it would have been much easier to skip the servo thing and just do the remote volume control by software however I wanted moving parts in there

because I like clockwork

Cheers

Attachments

Thanks fotios, yes, it is motorized. The quadrature encoder is made by Bourns and the Aluminum (7075 alloy) is made by ALCOA and machined to my spec.

Of course it would have been much easier to skip the servo thing and just do the remote volume control by software however I wanted moving parts in there

because I like clockwork

Cheers

Hmmm... So, is a custom made motorized encoder machined in a CNC milling machine. However, is a masterpiece of mechanical process. I like it very much, especially the ball bearing base

I had in my mind a different approach (based on my preference of the absolute isolation of the analog and digital part) which i will realize when i will have money left over

BTW, the frame of my MTB (a 12 years old "GT Pantera") is made from 6061 aluminum tubes, is this alloy good?

Happy Easter to all

a good alloy but not for a bike. Fatigue is the problem. Carbon and Titanium are very good for fatigue resistance, but they cost far to much to be classed as good.the frame of my MTB (a 12 years old "GT Pantera") is made from 6061 aluminum tubes, is this alloy good?

@ kct

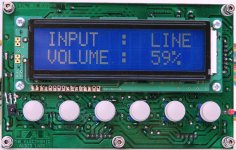

And here is mine volume control and the mcu unit.

Instead of an encoder, i use a traditional ALPS Blue Velvet motorized pot which of the shaft is joined with the shaft of a second 1KΩ mono linear pot thru a "couplier". The two pots are rotated simultaneously from the motor of ALPS. The wiper of the mono pot, is connected at the RA0 analog input of the (really excellent) PIC16F887 and its voltage level (proportional to the rotation angle of ALPS) is translated thru the program code in percentage which in sequence is displayed on the LCD screen.

And here is mine volume control and the mcu unit.

Instead of an encoder, i use a traditional ALPS Blue Velvet motorized pot which of the shaft is joined with the shaft of a second 1KΩ mono linear pot thru a "couplier". The two pots are rotated simultaneously from the motor of ALPS. The wiper of the mono pot, is connected at the RA0 analog input of the (really excellent) PIC16F887 and its voltage level (proportional to the rotation angle of ALPS) is translated thru the program code in percentage which in sequence is displayed on the LCD screen.

Attachments

- Home

- Amplifiers

- Solid State

- Post your Solid State pics here