lol fiberglass..yes, I mean no!

I'm thinking to use carbon fibre/kevlar

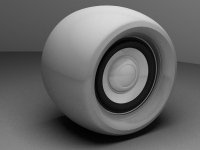

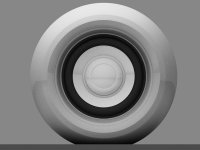

djn I have some earlier renderings but they aren't very good, I'll post some more when I can

I'm thinking to use carbon fibre/kevlar

djn I have some earlier renderings but they aren't very good, I'll post some more when I can

Last edited:

Well, what is the Q of the two drivers mentioned in that volume. Very small for a sub. Model it and see which works better.

Why the cost of CF or kevlar? Are you planning on launching it? How thick? Half an inch? Any internal core?

Why the cost of CF or kevlar? Are you planning on launching it? How thick? Half an inch? Any internal core?

Its just one driver with the amp plate mounted at the back, dimensions are 44x31cm atm. I'm making it in Thailand so the costs of composites are less than UK. The thickness is only a few mm and curvature makes it very stiff but I would brace if needed

How about a 1 cu foot enclosure with a 10" driver on each horizontal face? (4 of them) And about a 50% fill of activated coconut charcoal (with a good desiccant like 'molecular sieve') which should essentially double the internal compliance? That's something I might try if I was into that type of SW.

looks hard to make that shape

I have worked allot with both CF and Kevlar in my high power rocket building endeavors (in a past life).

I must say, the shape that you are going to try looks quite hard to do.

You may want to make a styrofoam core, cover it and melt the styrofoam out with Acetone.

I built a custom nosecone that way.

Anyway, good luck.

It looks like it will be a fast sub😀

Bob Evans farm in the backround

Dave

I have worked allot with both CF and Kevlar in my high power rocket building endeavors (in a past life).

I must say, the shape that you are going to try looks quite hard to do.

You may want to make a styrofoam core, cover it and melt the styrofoam out with Acetone.

I built a custom nosecone that way.

Anyway, good luck.

It looks like it will be a fast sub😀

Bob Evans farm in the backround

Dave

Last edited:

Not easy but I'll get the shape RP'd in 2 pieces then take a mold off - I love laying up carbon fibre, it stinks but its more fun than working in MDF

btw those rockets look great fun

Coconut charcoal?? I'll look into it 😉

btw those rockets look great fun

Coconut charcoal?? I'll look into it 😉

Last edited:

All this concern with building a round box, but nothing on modeling the driver in a volume to determine which driver is best suited, if either, for this box. Then no discussion of building a conventional prototype to confirm the design before embarking on an exotic build. Please, work through the design in the right order.

How about a 1 cu foot enclosure with a 10" driver on each horizontal face? (4 of them) And about a 50% fill of activated coconut charcoal (with a good desiccant like 'molecular sieve') which should essentially double the internal compliance? That's something I might try if I was into that type of SW.

I guess you have not had the time yet to study the relationship of T/S parameters and how it relates to a box volume. I really encourage you do do a bit of background reading, or show me a 10 inch sub driver that can work in a quarter cubic foot. One foot is pretty small for a SINGLE 10 inch drier. No stuffing identified so far is going to give more than about 10 to 15% volume equivalent. A Q of 2 and massive eq does not a high fidelity system make. Sunfire proved that.

either the RSS265HF or SB acoustics SW26DAC76-4 both work well just under 1 cuft sealed but will probably got for the Dayton; rough calculations inc amp, driver and some bracing internal vol comes out around 25litres

I've modelled about 50 drivers

I've modelled about 50 drivers

Last edited:

Coconut charcoal?? I'll look into it

KEF did a white paper on this a few years back and designed some HT speakers that used coconut charcoal for compliance enhancement.

Your system does look really cool, especially against the brushed Aluminum drywall.

.

Very futuristic. I love it.

Dave

.

Very futuristic. I love it.

Dave

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- 1 cu ft sealed sub design