How about a 1 cu foot enclosure with a 10" driver on each horizontal face? (4 of them) And about a 50% fill of activated coconut charcoal (with a good desiccant like 'molecular sieve') which should essentially double the internal compliance? That's something I might try if I was into that type of SW.

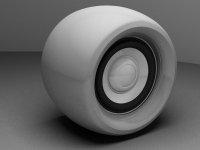

looks hard to make that shape

I have worked allot with both CF and Kevlar in my high power rocket building endeavors (in a past life).

I must say, the shape that you are going to try looks quite hard to do.

You may want to make a styrofoam core, cover it and melt the styrofoam out with Acetone.

I built a custom nosecone that way.

Anyway, good luck.

It looks like it will be a fast sub

Bob Evans farm in the backround

Dave

I have worked allot with both CF and Kevlar in my high power rocket building endeavors (in a past life).

I must say, the shape that you are going to try looks quite hard to do.

You may want to make a styrofoam core, cover it and melt the styrofoam out with Acetone.

I built a custom nosecone that way.

Anyway, good luck.

It looks like it will be a fast sub

Bob Evans farm in the backround

Dave

Last edited:

All this concern with building a round box, but nothing on modeling the driver in a volume to determine which driver is best suited, if either, for this box. Then no discussion of building a conventional prototype to confirm the design before embarking on an exotic build. Please, work through the design in the right order.

How about a 1 cu foot enclosure with a 10" driver on each horizontal face? (4 of them) And about a 50% fill of activated coconut charcoal (with a good desiccant like 'molecular sieve') which should essentially double the internal compliance? That's something I might try if I was into that type of SW.

I guess you have not had the time yet to study the relationship of T/S parameters and how it relates to a box volume. I really encourage you do do a bit of background reading, or show me a 10 inch sub driver that can work in a quarter cubic foot. One foot is pretty small for a SINGLE 10 inch drier. No stuffing identified so far is going to give more than about 10 to 15% volume equivalent. A Q of 2 and massive eq does not a high fidelity system make. Sunfire proved that.

Coconut charcoal?? I'll look into it

KEF did a white paper on this a few years back and designed some HT speakers that used coconut charcoal for compliance enhancement.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- 1 cu ft sealed sub design