Thanks guys!

Well, to be honest, I've quite literally followed the LTSpice schematic for layout of the components, including the Vcc and GND rail. I'm more than willing to make a picture of the solder-side, but I doubt it'll help much, since it's a veroboard. Let me know.

Well I think it can't harm, it just depends on your eagerness! I think that since it works, it is a follow-me example after all. 🙂

Ok, but don't bash my vero-board skills 😀

Hahaha, be sure that I won't! Nice work, thanks. 🙂

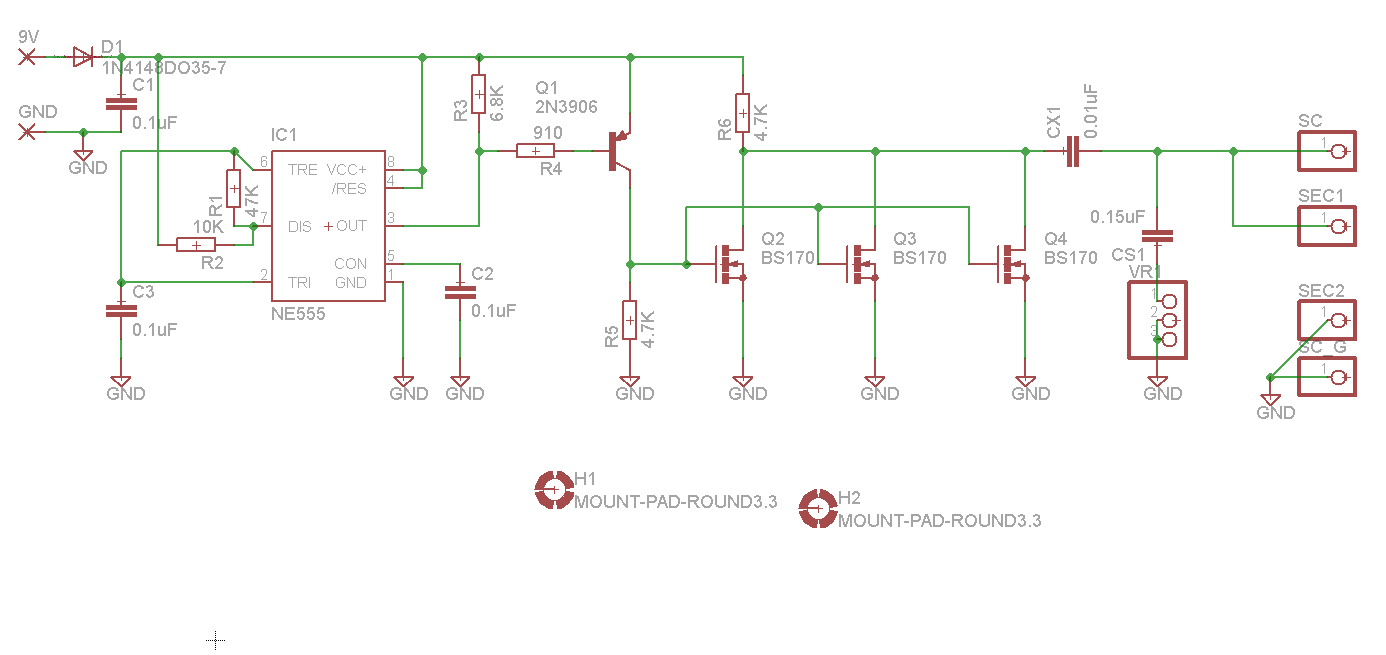

Today I made a quick PCB layout of a CheapoModo using the single-PNP gate driver circuit. I sent the attached .zip file of Gerber data & got the attached price quote back from OSH Park: $13.75 for 3 boards, and shipping is free (inside the USA anyway). Schematic is attached.

I'll receive the boards back from OSH Park in 2-3 weeks, and stuff+solder them to see whether they work. It's not a complicated design so I think the prognosis is excellent.

If anyone here would like to download the PCB data and order their own boards, here are the files. I suspect you'll have an easy time finding people who'd like to have any & all extra blank boards you're willing to sell or to give away.

BEWARE: the layout assumes an E-B-C pinout of the bipolar transistor (e.g. the 2N3906). The BC547 does not have this pinout. Check your datasheet!

I'll receive the boards back from OSH Park in 2-3 weeks, and stuff+solder them to see whether they work. It's not a complicated design so I think the prognosis is excellent.

If anyone here would like to download the PCB data and order their own boards, here are the files. I suspect you'll have an easy time finding people who'd like to have any & all extra blank boards you're willing to sell or to give away.

BEWARE: the layout assumes an E-B-C pinout of the bipolar transistor (e.g. the 2N3906). The BC547 does not have this pinout. Check your datasheet!

Attachments

Hi all, Forgive me if this is a stupid question, but will this device be usable with an old analog scope with no capture functionality. i.e. does it continuously ring the transformer in such a fashion the scope will be able to trigger on it and hold a stable image.

Yes.

But the signal is very narrow and quite low.

You need to use the timing switch to get one cycle on screen after you have found the very narrow resonant peaks.

Then use the expand facility to see the ripple at the peaks.

I use the invert on the trigger to swap between the rising and falling waveforms.

The ripple is present when VR is set to highest (as if the Zobel was not there)

The ripple is present when VR is set to zero (as if the single capacitor was inserted without a snubbing resistor).

I can see the null somewhere in the range from max to min resistance. I am finding a range of resistance from 5r to 500r for a wide range of transformer VA.

I use a 1k VR. But I think I will add a (pluggable) 100r VR for the bigger transformers.

I never got any guidance on how fast the edges need to be with the Cheapo, but my 1us times seem to show the effect.

I don't know if the required resistance values would be different using the fast Quasimodo.

It is 30 to 300 times faster than my version of the cheapo.

But the signal is very narrow and quite low.

You need to use the timing switch to get one cycle on screen after you have found the very narrow resonant peaks.

Then use the expand facility to see the ripple at the peaks.

I use the invert on the trigger to swap between the rising and falling waveforms.

The ripple is present when VR is set to highest (as if the Zobel was not there)

The ripple is present when VR is set to zero (as if the single capacitor was inserted without a snubbing resistor).

I can see the null somewhere in the range from max to min resistance. I am finding a range of resistance from 5r to 500r for a wide range of transformer VA.

I use a 1k VR. But I think I will add a (pluggable) 100r VR for the bigger transformers.

I never got any guidance on how fast the edges need to be with the Cheapo, but my 1us times seem to show the effect.

I don't know if the required resistance values would be different using the fast Quasimodo.

It is 30 to 300 times faster than my version of the cheapo.

Last edited:

A reader cautioned me that the 1N5819 Schottky diode may not qualify as a "junkbox part," and he's right. I apologize.

That diode's purpose is to protect CheapoModo in case the user accidentally connects the battery or power supply backwards. A Schottky diode is slightly better in this application because its forward voltage drop is lower, but just about ANY diode, silicon or Schottky, with >15V max reverse voltage, will work fine: 1N4148, 1N400x, BYV26, BA159, whatever's in your junkbox.

And of course you could just install a jumper wire instead of D1. You may not want or need this kind of protection.

That diode's purpose is to protect CheapoModo in case the user accidentally connects the battery or power supply backwards. A Schottky diode is slightly better in this application because its forward voltage drop is lower, but just about ANY diode, silicon or Schottky, with >15V max reverse voltage, will work fine: 1N4148, 1N400x, BYV26, BA159, whatever's in your junkbox.

And of course you could just install a jumper wire instead of D1. You may not want or need this kind of protection.

Attachments

Well it seems my analog scope has no issues picking up this trace, though i can only just get it to display the initial ring. I didn't even have to use the x10 magnification mode.

In the test images i was using a cheap 5va 6v transformer that came from eBay china. With no Cs capacitor i quickly got the scope dialed in on the ringing, and with a little experimentation i ended up with a 100nf in the Cs position, and the pot set to ~ 55ohms to produce a flat line. It certainly seems to work, now i just need to learn how to use it properly 🙂

Cheers Mark!

In the test images i was using a cheap 5va 6v transformer that came from eBay china. With no Cs capacitor i quickly got the scope dialed in on the ringing, and with a little experimentation i ended up with a 100nf in the Cs position, and the pot set to ~ 55ohms to produce a flat line. It certainly seems to work, now i just need to learn how to use it properly 🙂

Cheers Mark!

Attachments

Does it vary with primary winding that is shorted, open, or loaded with characteristic impedance ?

mcandmar, I recommend you connect a fixed inductor whose inductance is known within 10%, to Cheapomodo. Then calculate the ideally perfect Rs value which gives zeta=1.000 (at this L and this Cx) using the equation in Appendix A. Set your potentiometer to this Rs value. Look at the CheapoModo waveform on your scope; at the ideal perfect zeta=1.000, your scope trace is not a flat line. The goal is not to achieve a flat line, the goal is to achieve zeta=1.000. The ideal perfect scope waveform for zeta=1.000 is shown in post #143 of the Quasimodo thread, and in several Figures of the design note.

Mark any news on the osh park pcb ? Are they safe for ordering?

Thanks a lot for a very nice idea and implementation

Thanks a lot for a very nice idea and implementation

Mark any news on the osh park pcb ? Are they safe for ordering?

I built it and found that I hated it. The board functioned correctly, and I successfully used it to find zeta=1 snubbers for a few transformers. Despite this I hated it.

Why did I hate it: because it has too few external I/O pins. In particular, it doesn't have pins for the transformer secondary AND for the oscilloscope probe & groundclip. To use the board you have to wire up a little shiite-rig of crocodile clip jumpers, which connect the board to the transformer AND to the scope probe. Bleah.

So I tweaked the board design and made a rev.2. It worked and I didn't hate it. There were plenty of I/Os for the transformer and for the scope probe. Maybe I'll upload the PCB fab "Gerber" files in a few weeks, if I can eventually find them. Stuff is kinda jumbled up around here.

If anyone on DIYaudio wants to lay out a CheapoModo PCB, and share it with others (or sell it), please go right ahead. You have my blessings and good wishes.

Fair enough.

Do you guys mind having a look at my schematic to verify that I have not done any booboo?

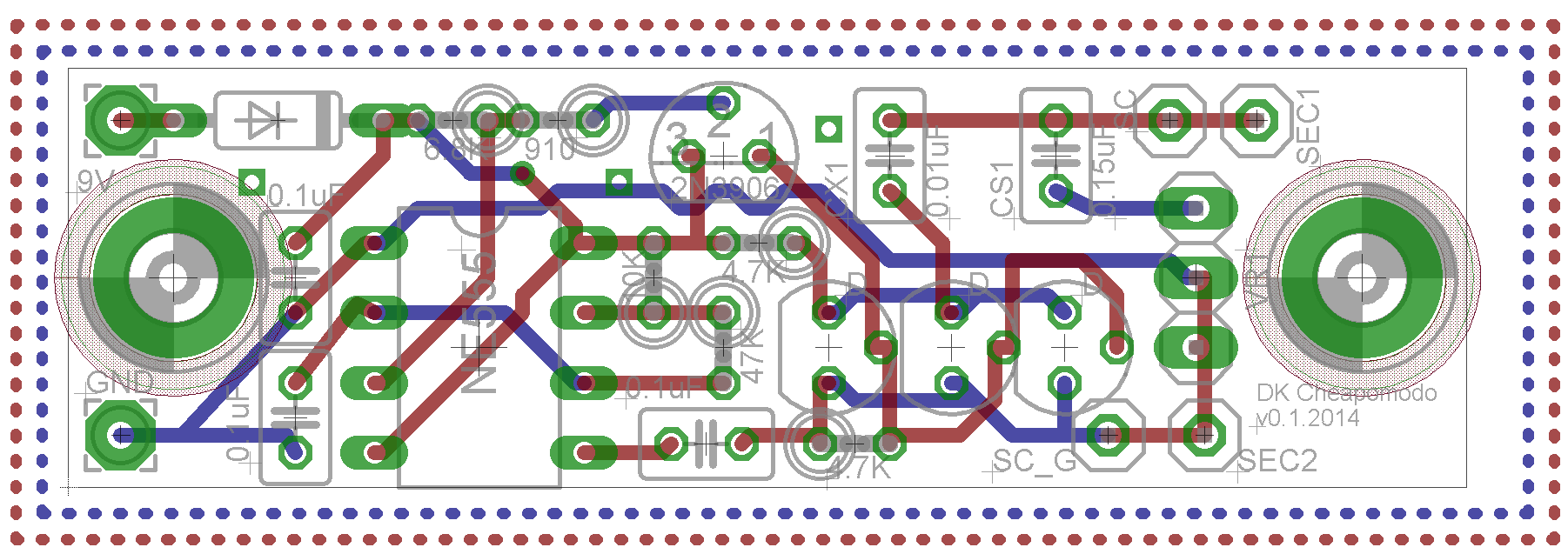

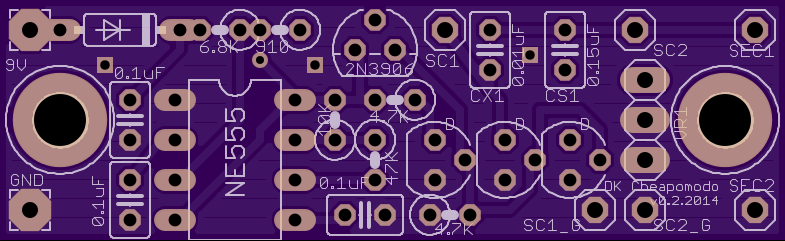

And here is the board

It's 51x16mm and cost is going to be 6 dollars for 3 pieces from OSH park, including shipment...

How is that for a cheapo? 🙂

Any comments more than welcome. I plan to order the samples at the end of the week.

Do you guys mind having a look at my schematic to verify that I have not done any booboo?

And here is the board

It's 51x16mm and cost is going to be 6 dollars for 3 pieces from OSH park, including shipment...

How is that for a cheapo? 🙂

Any comments more than welcome. I plan to order the samples at the end of the week.

Attachments

Here we go 🙂

Pins for two channel scopes, holes to attach clips to grab the secondaries, fixed width 10nF and 150nF caps (it is a cheapo anyway), mosfet drains marked with D to help orient the device of your choice and a 3pin socket for a trimmer.

Oh and it is a tiny bit smaller, so it now costs 5,85 for three pieces 🙂

Have I forgotten anything?

Pins for two channel scopes, holes to attach clips to grab the secondaries, fixed width 10nF and 150nF caps (it is a cheapo anyway), mosfet drains marked with D to help orient the device of your choice and a 3pin socket for a trimmer.

Oh and it is a tiny bit smaller, so it now costs 5,85 for three pieces 🙂

Have I forgotten anything?

Attachments

Will you include a GND flood on both blue and maroon layers? The naked via next to CS1 suggests that you will. It would be a good idea.

I don't see any electrolytic bypass caps; check your deltaV = (deltaT * I / C) calculations to be sure the supply ripple will be okay when operating from a 9V battery with its relatively high internal resistance.

If you're going to discard the 2N7000 junkbox MOSFET anyway, why not replace it with a low-RDSon TO-92 MOSFET ? The one in the attachment has the same pinout as your BS170, but 15X lower Rds. You could build one of your 3 boards with good FETs and the other 2 boards with cheap FETs and see if there's a difference. {On high current 6.3VAC heater windings/transformers, there may indeed be}

I don't see any electrolytic bypass caps; check your deltaV = (deltaT * I / C) calculations to be sure the supply ripple will be okay when operating from a 9V battery with its relatively high internal resistance.

If you're going to discard the 2N7000 junkbox MOSFET anyway, why not replace it with a low-RDSon TO-92 MOSFET ? The one in the attachment has the same pinout as your BS170, but 15X lower Rds. You could build one of your 3 boards with good FETs and the other 2 boards with cheap FETs and see if there's a difference. {On high current 6.3VAC heater windings/transformers, there may indeed be}

Attachments

Yes ground planes on both sides.

I used the BS170 because I saw it as an alternative on a previous post and I found it in the eagle libraries. I m keeping a note for the Zetex 🙂 It is available on mouser for about a euro.

About the electrolytic bypass, I got a rush as soon as I saw that function 🙂

Any rough guestimates on what should be used? Something like low esr 100uF?

I used the BS170 because I saw it as an alternative on a previous post and I found it in the eagle libraries. I m keeping a note for the Zetex 🙂 It is available on mouser for about a euro.

About the electrolytic bypass, I got a rush as soon as I saw that function 🙂

Any rough guestimates on what should be used? Something like low esr 100uF?

Last edited:

One more successful Cheapomodo

Similar to the previous poster, I also used BC556/546, some BS170 mosfets and a prototype board to produce a cheapomodo.

It works like a charm, thanks a bunch Mark.

Similar to the previous poster, I also used BC556/546, some BS170 mosfets and a prototype board to produce a cheapomodo.

It works like a charm, thanks a bunch Mark.

Attachments

Congratulations Oliphant! Nice power supply (homebrew?) in photo 3.

I assume the unconnected transformer wire in photo 3 is an electrostatic shield, rather than a primary winding connection?

I assume the unconnected transformer wire in photo 3 is an electrostatic shield, rather than a primary winding connection?

- Home

- Amplifiers

- Power Supplies

- CheapoModo: quick and dirty transformer snubber bellringer jig